High performance concrete composite mineral additive prepared from construction wastes and preparation method thereof

A high-performance concrete and construction waste technology, applied in the field of comprehensive utilization of construction waste, can solve the problems of sand powder utilization, secondary environmental pollution, etc., and achieve the effect of fine fineness, high product activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-performance concrete composite mineral admixture utilizing construction waste is prepared from construction waste powder with a weight of 300kg, slag powder with a weight of 400kg and fly ash with a weight of 300kg.

[0028] Its preparation method comprises the following steps:

[0029] (1) Pretreatment of construction waste powder: the collected construction waste is dedusted and collected powder, sieved to remove coarse particles with a particle size larger than 0.16cm, and collect powder with a particle size smaller than 0.16cm, and pass through the conveying equipment Continuously mixed and collected into construction waste powder;

[0030] (2) Raw material weighing: weigh construction waste powder, slag powder and fly ash according to the above weight;

[0031] (3) The construction waste powder, slag powder and fly ash in step (2) are transported to a gravity-free mixer for homogenization;

[0032] (4) The powder homogenized in step (3) is supplied to the ...

Embodiment 2-8

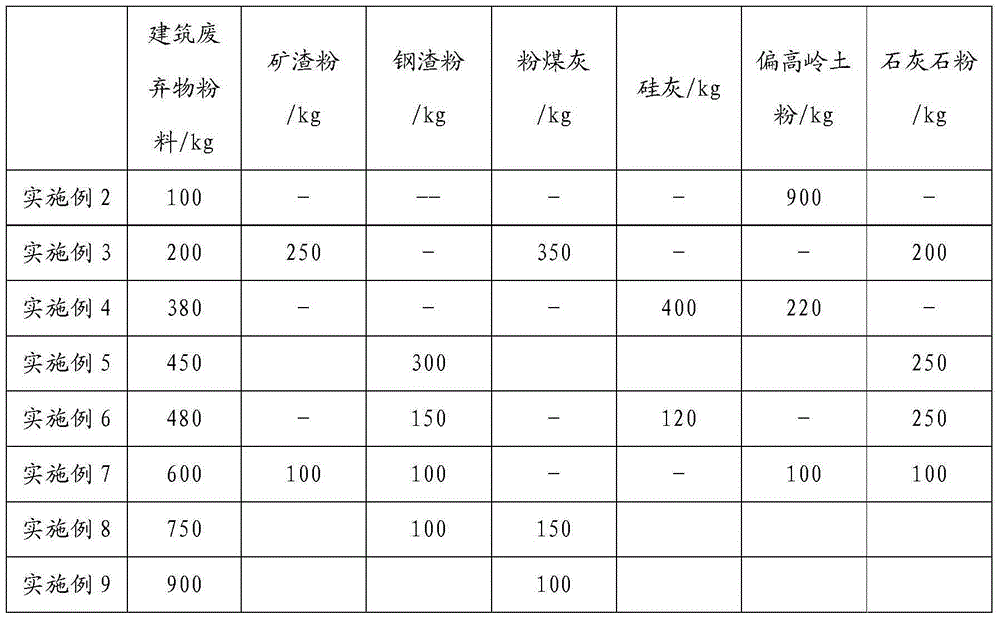

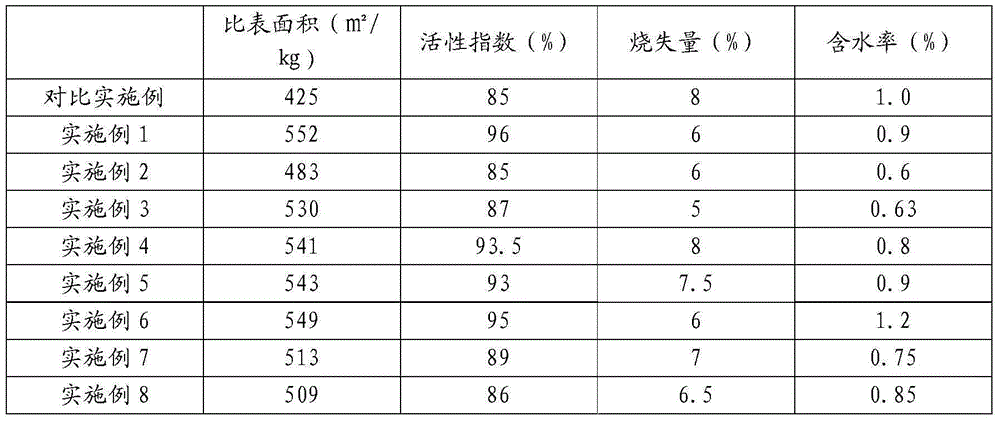

[0034] The raw materials were weighed according to the proportions in Table 1, and prepared according to the steps in Example 1. The difference is that the added raw material proportions are different, and the products are prepared. See Table 1 for details:

[0035] Table 1: Raw material ratio table of embodiment 2-8

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com