Preparation method of catagraphites slabs

The technology of stone plate and pattern is applied in the field of preparation of artificial pattern stone plate, which can solve the problems of high production cost, complicated method and process, and achieve the effect of strong workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

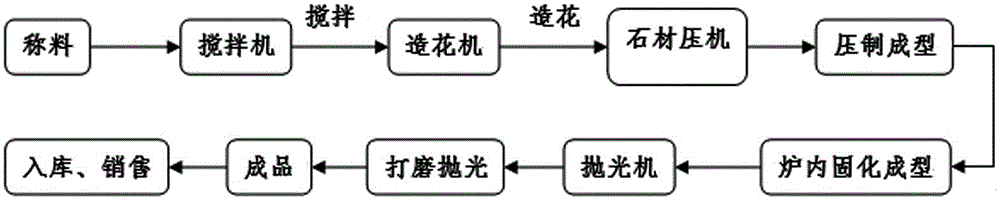

Method used

Image

Examples

Embodiment 1

[0022] Get raw material by weight as follows:

[0023] Unsaturated polyester resin 8kg, curing agent methyl ethyl ketone peroxide 0.4kg, quartz powder 40kg, glass fiber 25kg, color paste 0.2kg, coupling agent 0.3kg, alloy powder 0.1kg, composite powder 24kg, water 2kg.

[0024] Add unsaturated polyester resin into the mixing tank, add compound powder during high-speed stirring, stir for 16 minutes, mix well, continue stirring for 15 minutes until well mixed. Add the color paste and accelerator into the mixing tank, and stir at high speed for 5 minutes to mix well. Wait for 10 minutes, add curing agent, and continue to stir for 10 minutes until the mixture is uniform. Put the uniformly mixed raw materials into the flower making machine for flower making treatment, then cut the glass fiber according to the surface size of the mold and place it inside the mold. Pour the homogeneously mixed raw materials that have undergone flower-making treatment into the mold quickly, solidify...

Embodiment 2

[0026] Unsaturated polyester resin 9kg, curing agent methyl ethyl ketone peroxide 0.4kg, quartz powder 40kg, glass fiber 24kg, color paste 0.2kg, coupling agent 0.3kg, alloy powder 0.1kg, composite powder 25kg, water 1kg.

[0027] Add unsaturated polyester resin into the mixing tank, add compound powder during high-speed stirring, stir for 18 minutes, mix well, continue stirring for 16 minutes until well mixed. Add the color paste and accelerator into the mixing tank, and stir at high speed for 8 minutes to mix well. Wait for 10 minutes, add curing agent, and continue to stir for 12 minutes until the mixture is uniform. Put the uniformly mixed raw materials into the flower making machine for flower making treatment, then cut the glass fiber according to the surface size of the mold and place it inside the mold. Pour the homogeneously mixed raw materials that have undergone flower-making treatment into the mold quickly, and solidify at room temperature for 20 minutes to make i...

Embodiment 3

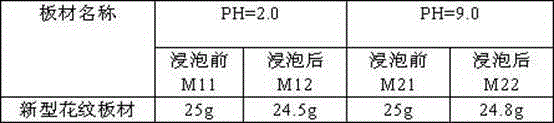

[0029] Anti-corrosion test of pattern stone plate:

[0030] (1) Take two small pieces of the finished product in Example 1 or 2, divide them into two parts and mark them as A and B, weigh and record the corresponding masses as m1 and m2.

[0031] (2) Prepare 500mL of PH=2 acidic solution and 500mL of pH=9 alkaline solution.

[0032] (3) Put the two stones to be tested, A and B, into the prepared PH=2 acidic solution and PH=9 alkaline solution and soak for 24 hours.

[0033] (4) Take out the two test stones A and B after soaking, weigh their masses M1 and M2, and observe their surface changes.

[0034] The experimental results show that the quality of the two test stones A and B has no obvious change before and after soaking, and there is no obvious change on the surface of the stone, which shows that the stone does not undergo chemical reactions with acid and alkali, and has excellent acid and alkali corrosion resistance.

[0035] Table 1 The mass change of the new pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com