An automatic continuous zinc white furnace

A zinc white furnace and automatic technology, applied in the field of non-ferrous metal smelting equipment and automatic continuous zinc white furnace, can solve the problems of large energy waste, high labor intensity, and a large number of manual operations, so as to reduce labor costs, reduce labor quantity, The effect of reducing unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

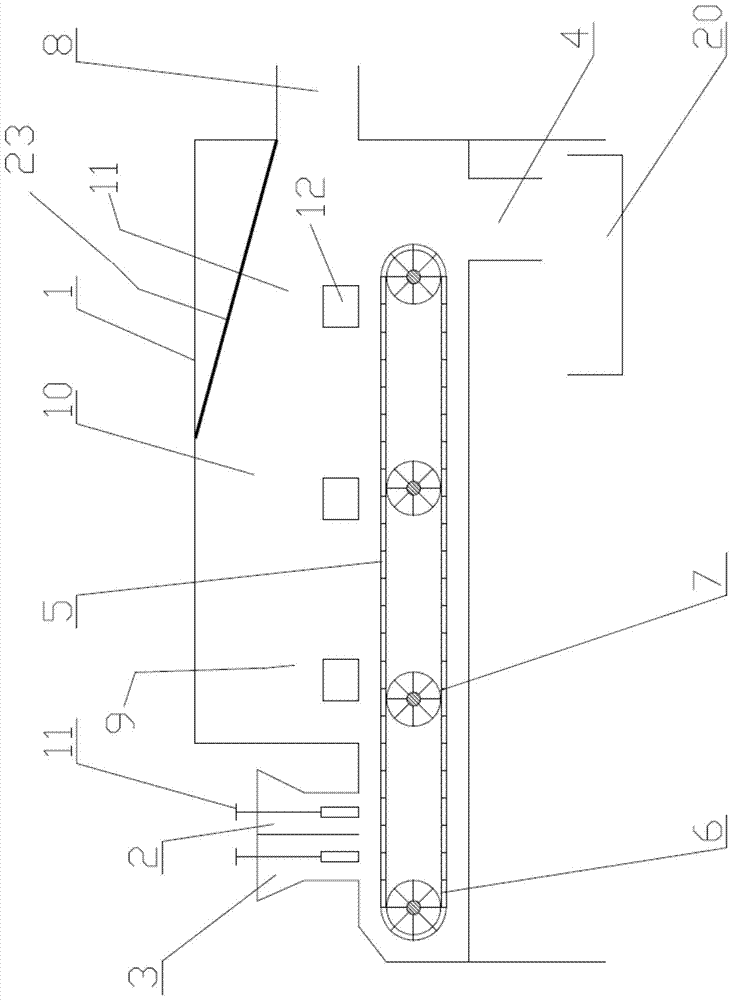

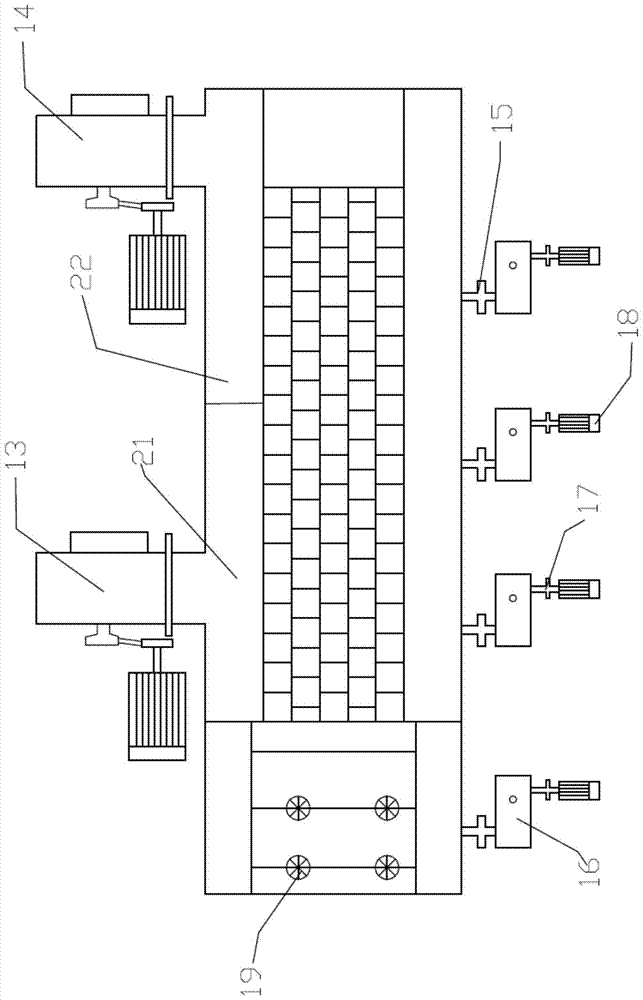

[0016] like figure 1 , figure 2 As mentioned above, each label in the figure is: 1, furnace body; 2, material distribution port; 3, coal distribution port; 4, slag discharge port; 5, crawler buckle; ;9, preheating area; 10, high temperature reaction area; 11, slag discharge area; 12, observation hole; 13, preheating blower; 14, high temperature blower; 15, driven shaft; 16, gear transmission mechanism; 17, active Shaft; 18, motor; 19, regulating valve; 20, pool; 21, preheating air duct; 22, high temperature air duct; 23, diversion layer.

[0017] An automatic continuous zinc white furnace according to the present invention comprises a furnace body 1; the upper front part of the furnace body 1 is provided with a material distribution port 2 and a coal distribution port 3, and the rear lower part of the furnace body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com