Automatic cotton kneading device

An automatic, cotton board technology, applied in the direction of fabric kneading/softening, textile and papermaking, fabric surface trimming, etc., can solve the problems of high production cost, low work efficiency, uneven batting, etc., and achieve low production and processing costs. , The effect of strong work stability and easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

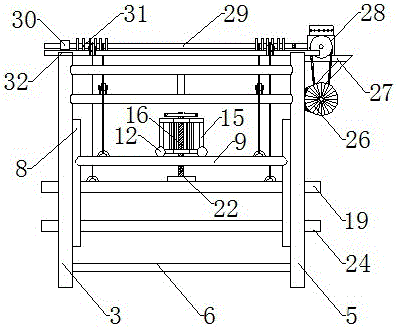

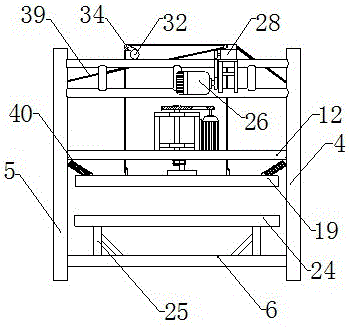

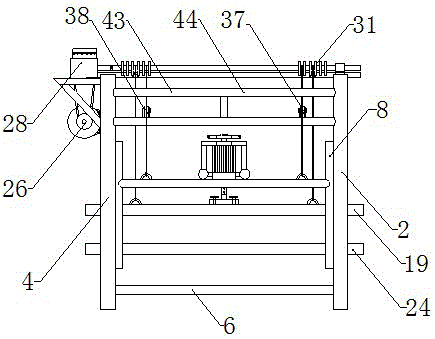

[0028] like figure 1 -Shown in 12: a kind of automatic kneading cotton device, comprises main frame 1, and described main frame 1 is the rectangular frame body that is built by steel pipe, and it comprises the pillar A2 that is arranged on four azimuths, pillar B3, pillar C4 and The pillar D5, between the pillar A2 and the pillar B3, between the pillar B3 and the pillar D5, between the pillar D5 and the pillar C4, between the pillar C4 and the pillar A2, is provided with a supporting pillar 6 near the bottom of the main frame 1, Between the pillar A2 and the pillar B3, between the pillar B3 and the pillar D5, between the pillar D5 and the pillar C4, between the pillar C4 and the pillar A2, there is a support frame 7 near the top of the main frame 1, which is characterized in that A slide rail 8 is arranged on the opposite side wall of the pillar A2 and the pillar C4, a slide rail 8 is also arranged on the opposite side wall of the pillar B3 and the pillar D5, and the main fram...

Embodiment 2

[0032] like figure 1 -Shown in 12: a kind of automatic kneading cotton device, comprises main frame 1, and described main frame 1 is the rectangular frame body that is built by steel pipe, and it comprises the pillar A2 that is arranged on four azimuths, pillar B3, pillar C4 and The pillar D5, between the pillar A2 and the pillar B3, between the pillar B3 and the pillar D5, between the pillar D5 and the pillar C4, between the pillar C4 and the pillar A2, is provided with a supporting pillar 6 near the bottom of the main frame 1, Between the pillar A2 and the pillar B3, between the pillar B3 and the pillar D5, between the pillar D5 and the pillar C4, between the pillar C4 and the pillar A2, there is a support frame 7 near the top of the main frame 1, which is characterized in that A slide rail 8 is arranged on the opposite side wall of the pillar A2 and the pillar C4, a slide rail 8 is also arranged on the opposite side wall of the pillar B3 and the pillar D5, and the main fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com