Novel natural antibacterial finishing agent, and preparation method thereof

A natural antibacterial and finishing agent technology, which is applied in fiber treatment, textiles, papermaking, plant fibers, etc., can solve the problems of susceptibility to bacterial growth, etc., and achieve the effect of improving antibacterial effect, good antibacterial effect, and improving inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

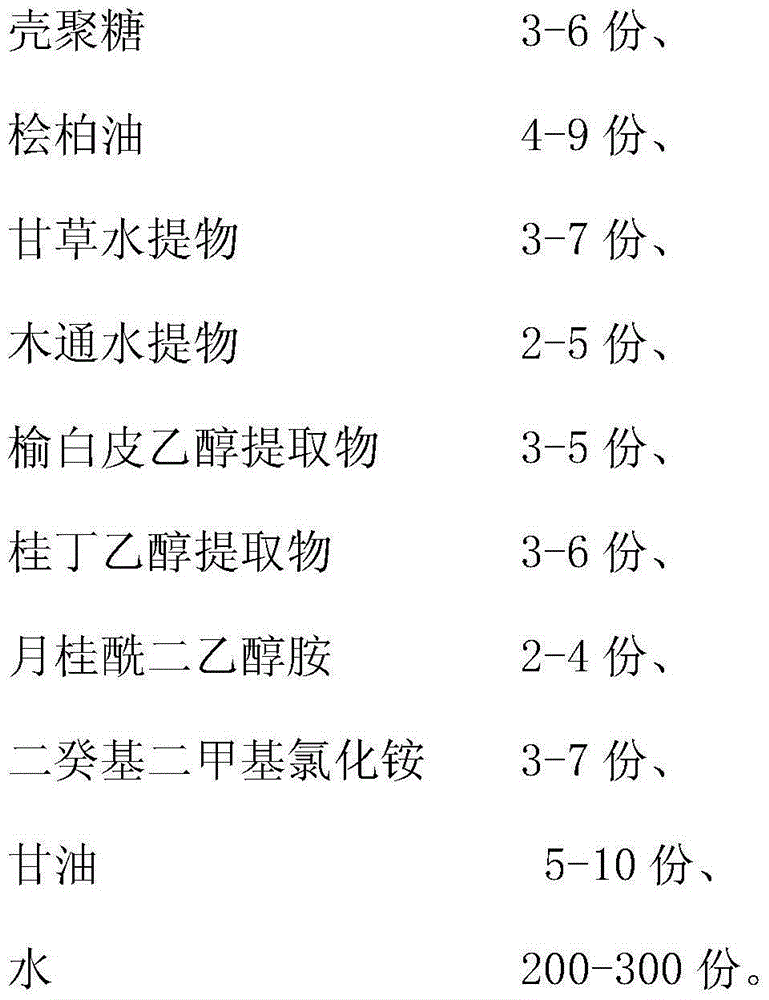

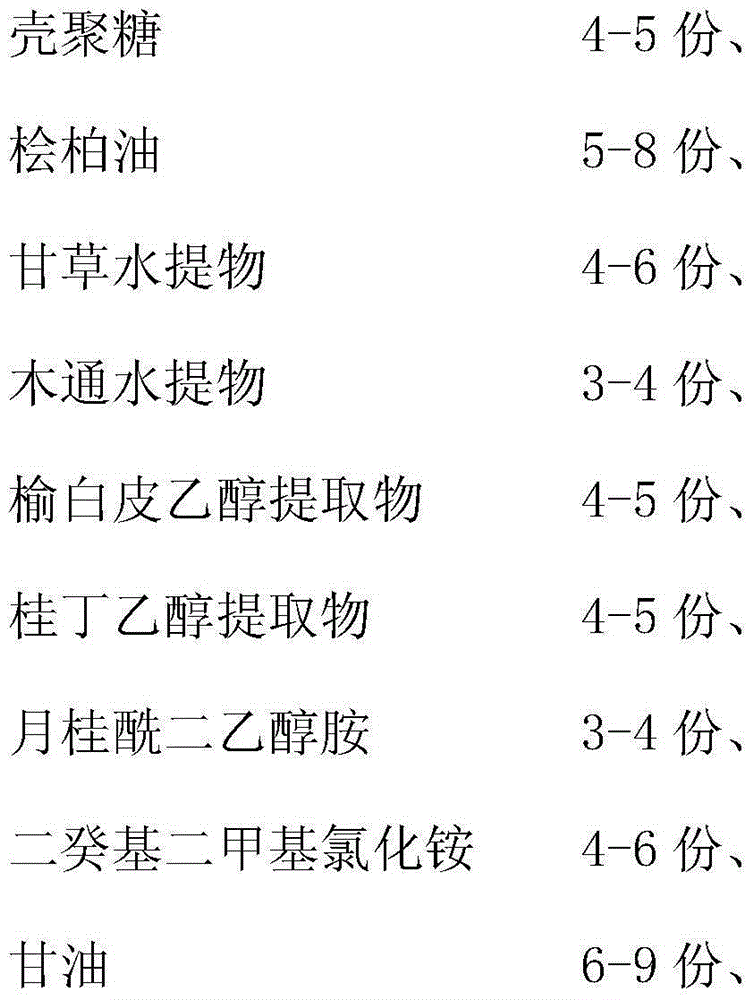

Embodiment 1

[0017] (1) Glycyrrhizae and Akebia were dried respectively, and after drying, they were pulverized respectively. After pulverization, hot-dip extraction was carried out with water respectively. The ratio of hot-dip extraction to material was 1:10. at 65°C, filter after hot leaching, vacuum film-dry the extracts respectively, and obtain licorice water extract and akebia water extract respectively after drying; Grinding, and then heating and extracting the powders of Yubaibapi and Guiding with ethanol, the ratio of solid to liquid is 1:6, the hot extraction time is 2h, and the hot extraction temperature is 60°C, and centrifuged after heating extraction , the supernatant was carried out vacuum film drying respectively, and it was Ulmus alba ethanol extract and cinnamon cinnamon ethanol extract; (3) respectively get 6 parts of chitosan, 9 parts of juniper oil, 3 parts of licorice water extract, 2 parts of Akebia water extract, 3 parts of Ulmus alba ethanol extract, 6 parts of cinn...

Embodiment 2

[0019] (1) Glycyrrhizae and Akebia were dried respectively, and after drying, they were pulverized respectively. After pulverization, hot-dip extraction was carried out with water respectively. The ratio of hot-dip extraction to material was 1:10. at 65°C, filter after hot leaching, vacuum film-dry the extracts respectively, and obtain licorice water extract and akebia water extract respectively after drying; Grinding, and then heating and extracting the powders of Yubaibapi and Guiding with ethanol, the ratio of solid to liquid is 1:6, the hot extraction time is 2h, and the hot extraction temperature is 60°C, and centrifuged after heating extraction , the supernatant liquid is carried out vacuum film drying respectively, is Ulmus alba ethanol extract and cinnamon din ethanol extract; (3) get respectively 3 parts of chitosan, 4 parts of juniper oil, 7 parts of licorice water extract by weight, 5 parts of Akebia water extract, 5 parts of Ulmus alba ethanol extract, 3 parts of c...

Embodiment 3

[0021] (1) Glycyrrhizae and Akebia were dried respectively, and after drying, they were pulverized respectively. After pulverization, hot-dip extraction was carried out with water respectively. The ratio of hot-dip extraction to material was 1:10. at 65°C, filter after hot leaching, vacuum film-dry the extracts respectively, and obtain licorice water extract and akebia water extract respectively after drying; Grinding, and then heating and extracting the powders of Yubaibapi and Guiding with ethanol, the ratio of solid to liquid is 1:6, the hot extraction time is 2h, and the hot extraction temperature is 60°C, and centrifuged after heating extraction , the supernatant was carried out vacuum film drying respectively, and it was Ulmus alba ethanol extract and cinnamon ding ethanol extract; (3) respectively get 5 parts of chitosan, 8 parts of juniper oil, 4 parts of licorice water extract, 3 parts of Akebia water extract, 4 parts of Ulmus alba ethanol extract, 5 parts of cinnamon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com