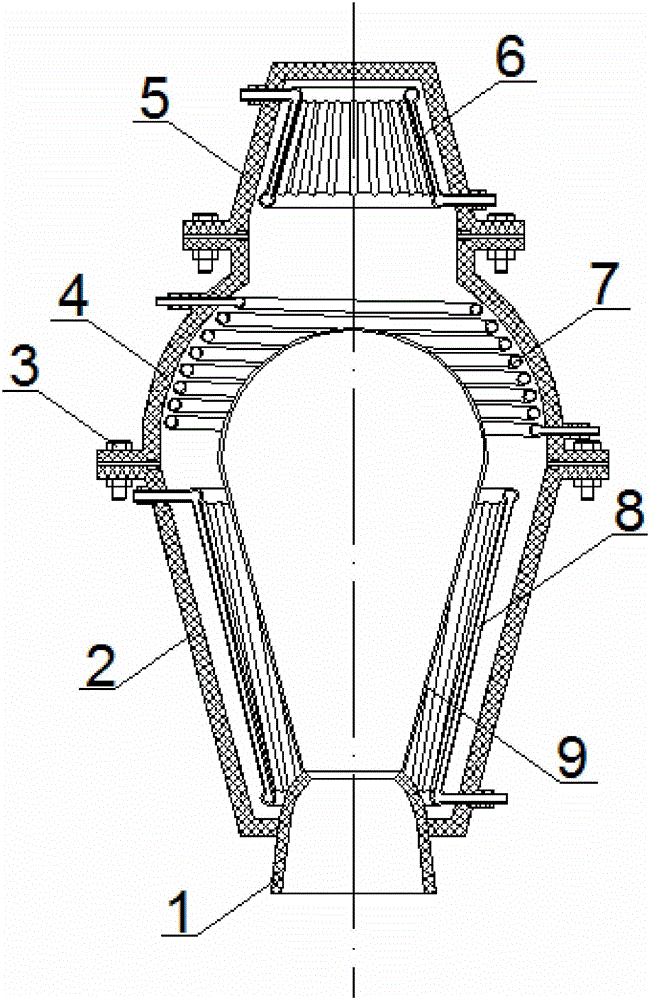

Composite cavity type solar absorber

A solar energy absorption and composite technology, which is applied in the field of cavity solar absorbers, can solve the problems of low photothermal conversion efficiency, inability to use on a large scale, and excessively long heat transfer coils. Heat loss, the effect of reducing heat conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

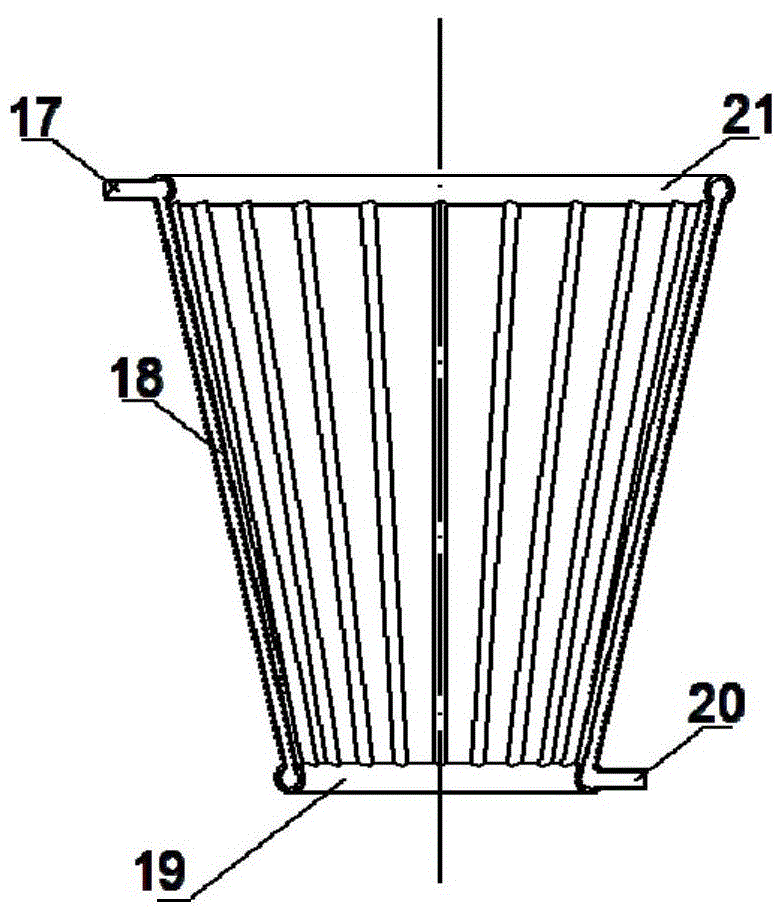

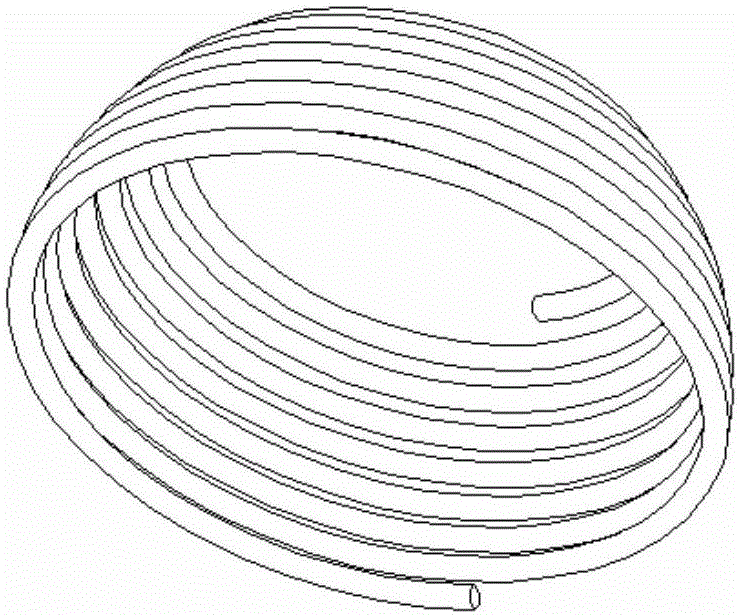

[0051] Embodiment: The device is fixed at the focal plane of the dish-type solar concentrator. When sunlight is irradiated during the day, water is passed into the inlet 20 of the low-temperature straight pipe. It can be used as a heat source after discharge. Extraction of low temperature molten KNO from cold brine tank 3 Enter the inlet pipe 16 of the middle temperature zone, and become high-temperature molten KNO after heating 3 Finally, it flows out from the medium temperature outlet pipe 15 and enters the hot brine tank for storage, and simultaneously extracts part of the high-temperature molten KNO from the hot brine tank. 3 Enter the steam generator to release heat, heat the water to generate steam to drive the steam turbine to generate electricity, release heat in the steam generator and cool the KNO 3 The molten salt enters the cold salt tank again.

[0052] The straight pipe in the high temperature area adopts a coaxial sleeve pipe filled with catalyst, and NH is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com