High-efficiency melting furnace of phase-changing heat storage medium

A phase-change heat storage and melting furnace technology, which is applied to furnaces, crucible furnaces, furnace types, etc., can solve the problems of large heat loss, increase the overall weight of equipment, and cannot be repaired, so as to reduce the heat resistance requirements of equipment and save equipment The effect of investing money and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

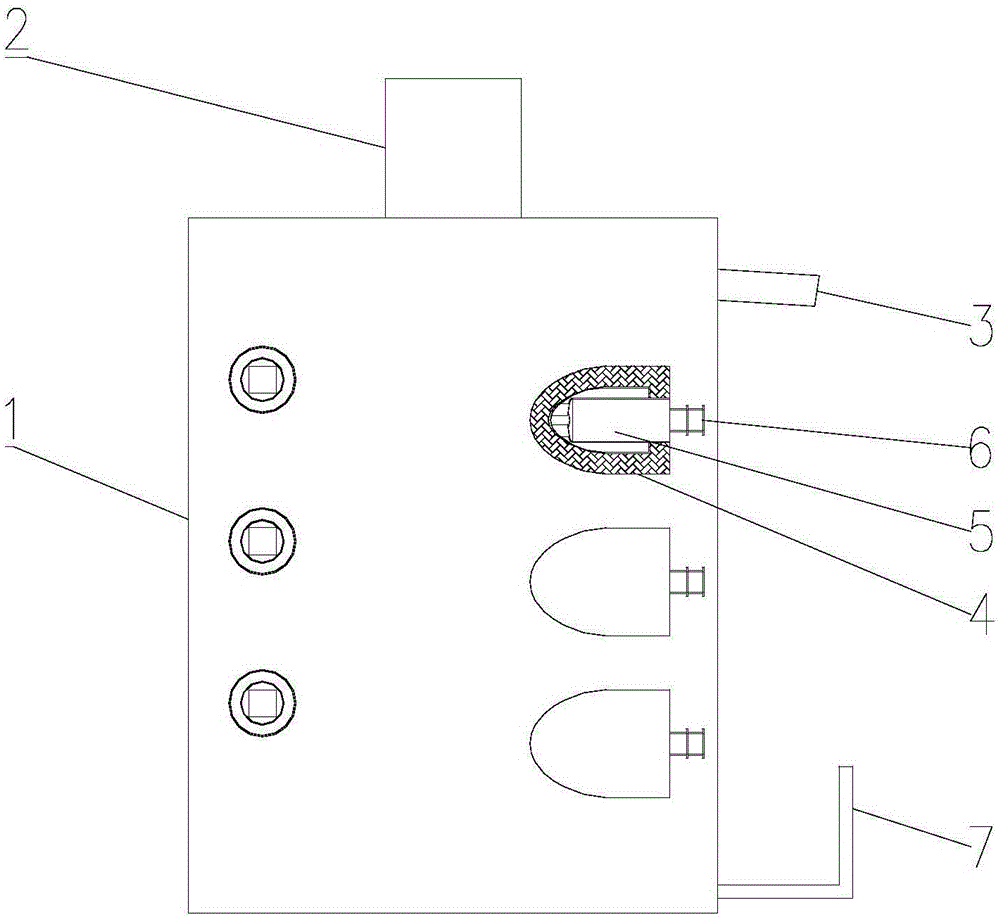

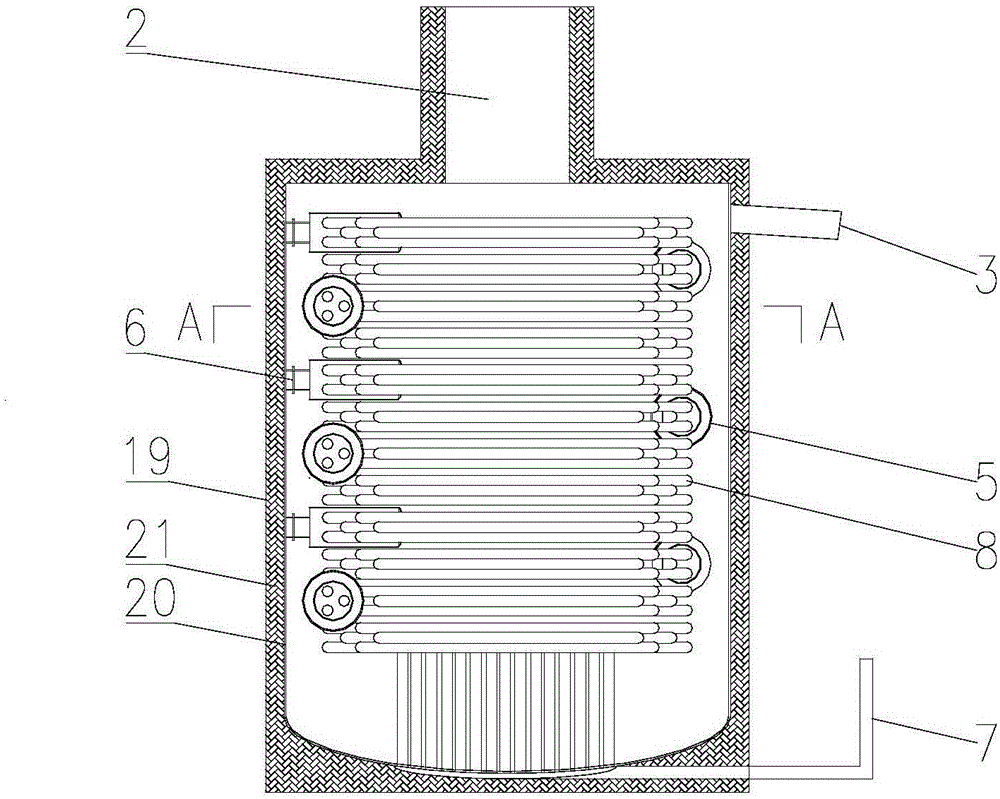

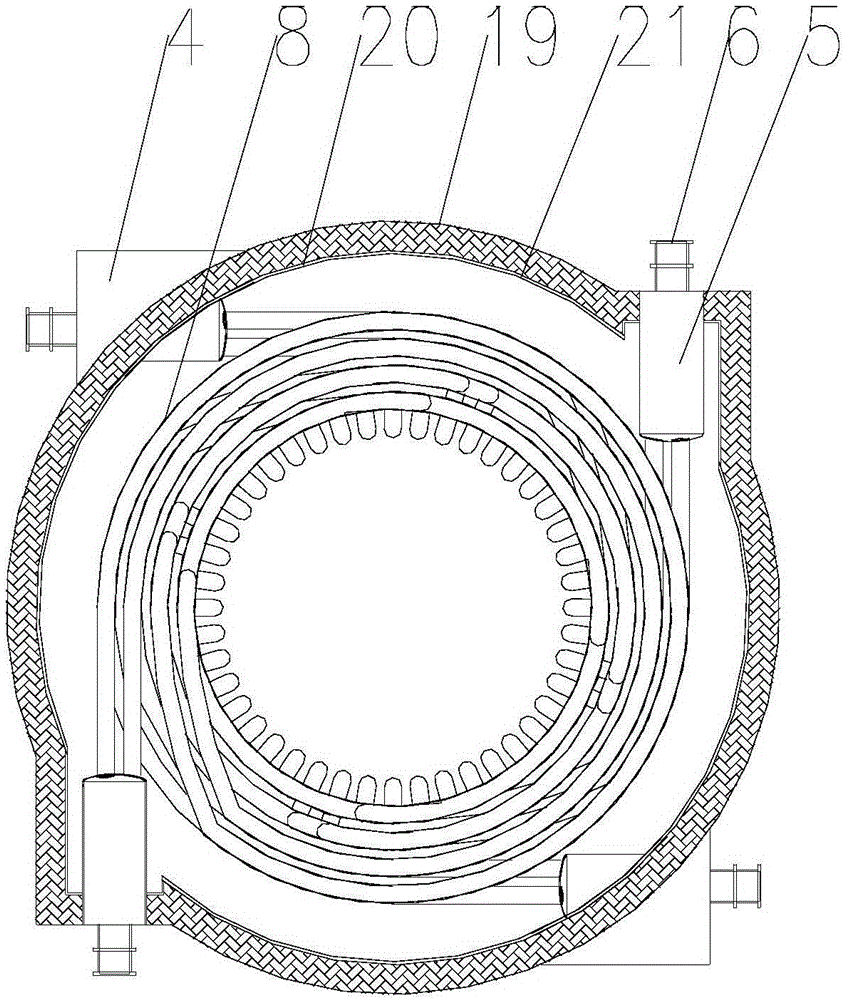

[0052] like Figure 1-Figure 3 As shown, a high-efficiency phase-change heat storage medium melting furnace includes:

[0053] Insulation cylinder 1, insulation cylinder 1 has a filling port 2 for filling phase change heat storage medium, and a discharge port 3 for discharging liquid phase change heat storage medium, and the outer wall of insulation cylinder 1 is provided with several The support pipe 4 that connects the inside and outside of the heat preservation cylinder 1, several support pipes 4 are evenly arranged on the outer wall of the heat preservation cylinder 1, a heating chamber 5 is fixed in the support pipe 4, and the heating chamber 5 is sealed and connected with the support pipe 4. The inside of the insulation cylinder 1 is isolated from the outside,

[0054] Heating burner 6, and heating burner 6 is fixedly arranged in heating chamber 5, and

[0055] The smoke exhaust pipe 7 , each heating chamber 5 and the smoke exhaust pipe 7 communicate with each other th...

Embodiment 2

[0067] like Figure 4 , Figure 5 As shown, a high-efficiency phase-change heat storage medium melting furnace has the same structure as that of Embodiment 1, the difference is that: the filling port 2 is provided with a sealed filling box 9 that prevents the hot gas in the melting furnace from overflowing, and the sealing Filling box 9 comprises box body 10, and box body 10 is provided with rotating shaft 11, and rotating shaft 11 is fixed with some sealing baffles 12 upwards, and the rotation of rotating shaft 11 is driven by drive motor 13 outside box body 10.

[0068] Preferably, several sealing baffles 12 are evenly arranged in the circumferential direction of the rotating shaft 11 .

Embodiment 3

[0070] like Image 6 , Figure 7 As shown, a high-efficiency phase-change heat storage medium melting furnace has the same structure as that of embodiment 1 or embodiment 2. The discharge port 3 is arranged on the upper part of the side wall of the melting furnace, and a discharge port 3 inside the insulation cylinder 1 is fixedly provided with a The baffle 14 used to prevent the solid phase-change heat storage medium added from the filling port 2 from entering the discharge port 3 .

[0071] Preferably, the baffle plate 14 , the inner wall of the insulation cylinder 1 and the top of the insulation cylinder 1 form a liquid phase-change heat storage medium discharge channel 15 with an opening at the bottom.

[0072] Preferably, the discharge channel 15 is provided with a vent 16 for releasing the air in the discharge channel 15 .

[0073] Preferably, the vent 16 is located at the top of the insulation cylinder 1 or at the side wall of the insulation cylinder 1 and above the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com