Tunnel junction cantilever beam content testing instrument

A cantilever beam, tunnel junction technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as high price, complex structure of instruments and equipment, and limitations of use occasions or application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

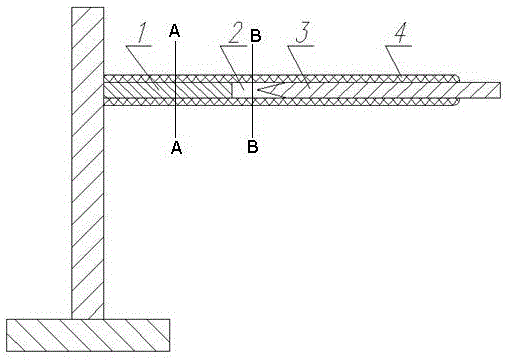

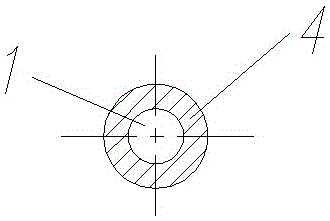

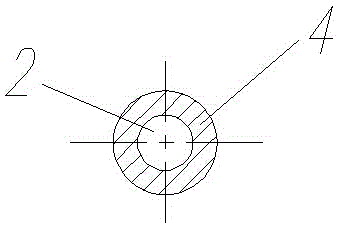

[0021] The specific implementation of a tunnel junction cantilever beam content measuring instrument of the present invention will be described below with reference to the accompanying drawings.

[0022] Such as figure 1 , figure 2 , image 3 As shown, there is a hole in the middle of a cantilever beam made of fiber, and metal electrode 1 and metal electrode 3 are arranged in the hole, and insulating fiber 4 wraps metal electrode 1 and metal electrode 3, leaving a distance between metal electrode 1 and electrode 3 2. The part of the metal electrode 3 close to the metal electrode 1 is in the shape of a needle point. The tester is a cantilever beam structure, and one or more pairs of tunnel junction electrodes are installed near the fixed end of the cantilever beam. The distance between two adjacent electrodes is 0.01nm-100nm, and the electrodes are insulated from the cantilever beam. The shape of the cantilever beam is uniform cross section or uneven cross section, the unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com