Method for establishing air pre-heater clean factor calculation model by using smoke pressure difference, and application

A cleaning factor and calculation model technology, applied in the field of establishing the calculation model of the air preheater cleaning factor, can solve the problems that cannot reflect the change of the area coefficient, the dust blocking of the air preheater, etc., so as to improve the calculation speed and simplicity, and reduce the operating cost. cost, the effect of improving safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

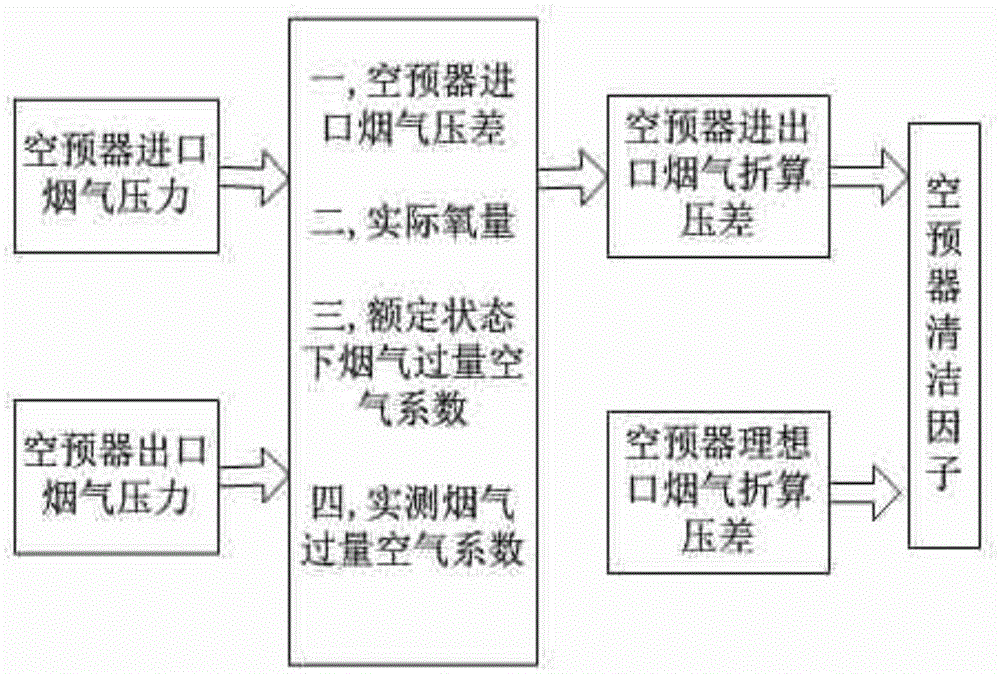

[0059] The present invention proposes a method for establishing an air preheater cleaning factor calculation model using the flue pressure difference method, comprising the following steps:

[0060] Step 1: First convert the actual measured pressure difference under different loads and excess air coefficients to the calculated value under the rated load, the calculation formula is as follows:

[0061] Δp z s = Δ p ( α 0 α × N 0 N ) 2 - - - ( 1 )

[0062] Among them, Δp ZS Represents the converted pressure difference, unit Pa; Δp represents the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com