Anode saturation reactor of direct-current converter valve

A DC converter valve and reactor technology, applied in the direction of transformer/inductor shell, transformer/inductor cooling, transformer/inductor magnetic core, etc., can solve the complexity of waterway design, complicated waterway and poor heat dissipation effect of iron core And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

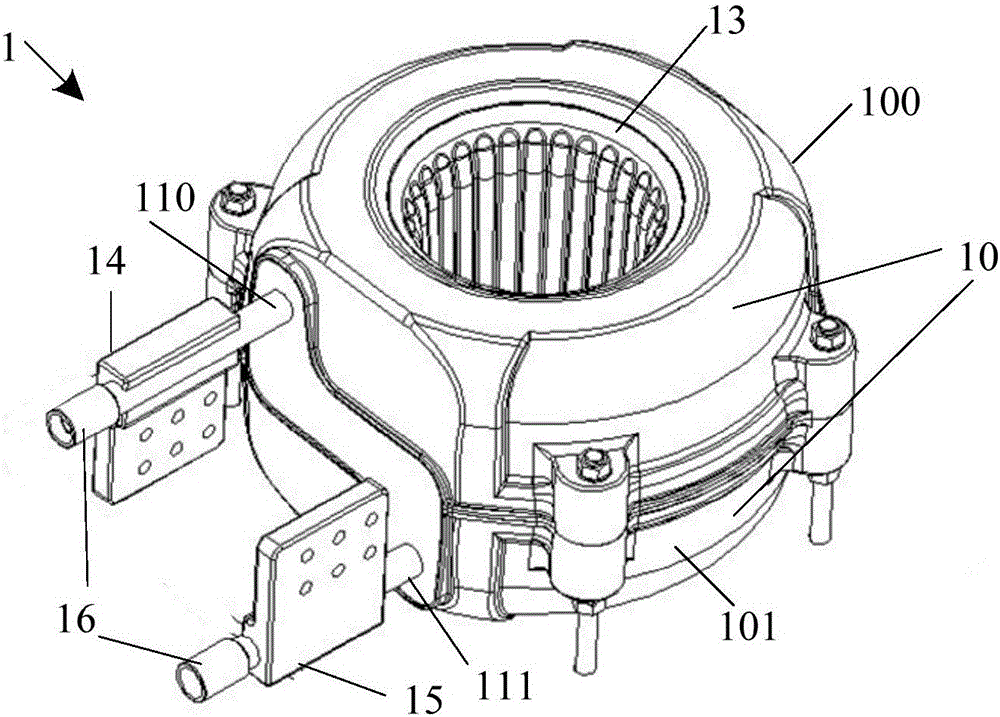

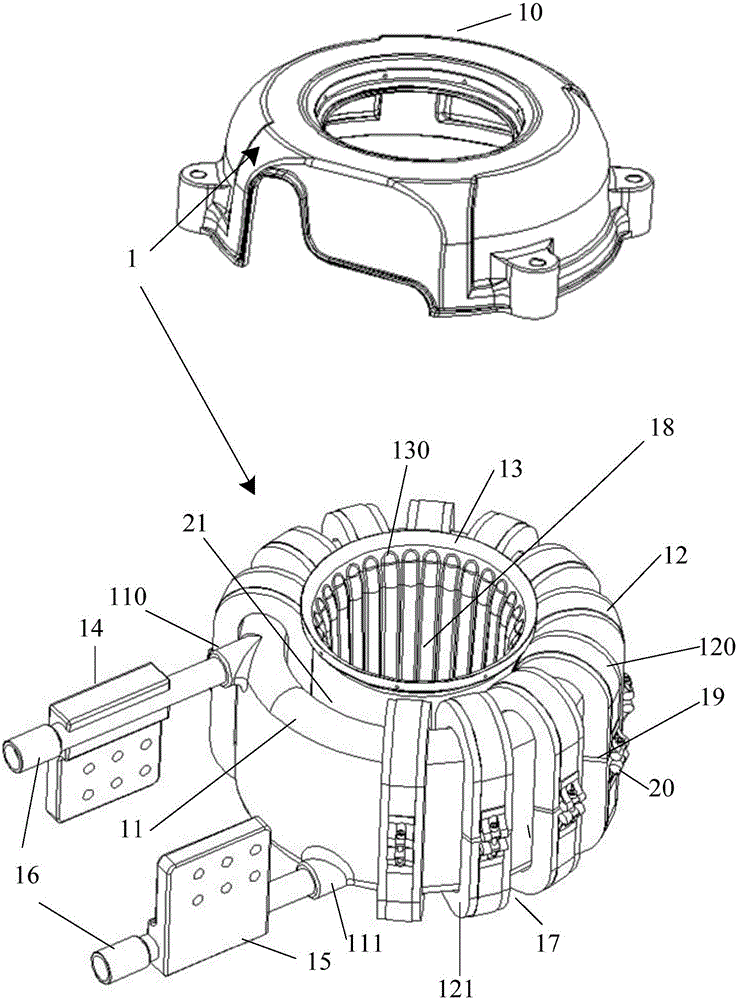

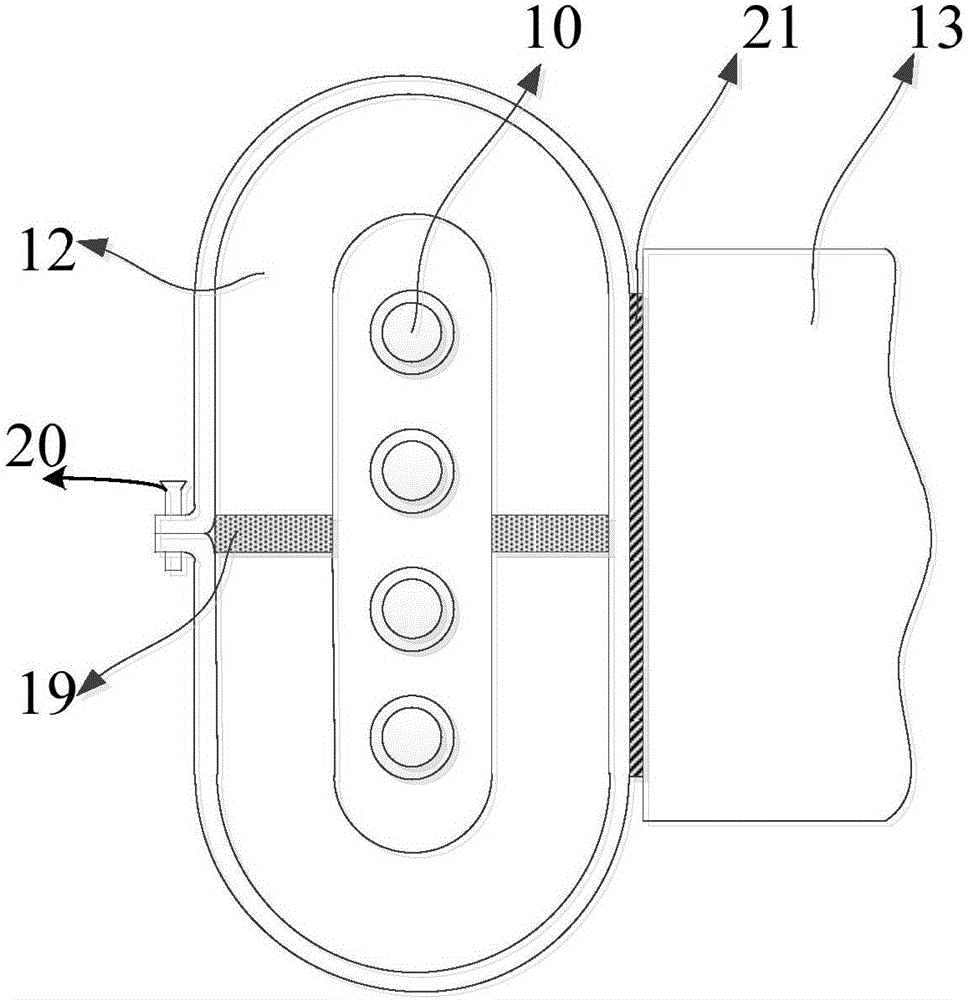

[0029] Exemplary combination figure 1 , figure 2 and image 3 It can be seen that the embodiment of the present invention provides an anode saturated reactor 1 for a DC converter valve, and the anode saturated reactor 1 for a DC converter valve includes: a casing 10, a set of coils 11, at least a pair of iron cores 12 and an iron core Radiator 13; each iron core 12 includes a first iron core part 120 and a second iron core part 121, and the first iron core part 120 and the second iron core part 121 are U-shaped structures up and down or C-shaped left and right structure.

[0030] The at least one pair of iron cores 12 is fastened in pairs between the inner and outer walls of the group of coils 11 to form a closed coupling.

[0031] The at least one pair of iron cores 12 is arranged along the circumferential direction of the group of coils 11 .

[0032] The core radiator 13 is arranged inside the inner wall of the group of coils 11, contacts with the at least one pair of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com