Microwave energy receiving plate

A technology of energy reception and microwave, applied in the direction of electromagnetic wave system, etc., can solve the problems of low energy conversion efficiency and lower energy utilization rate, and achieve the effects of variable structure, improved efficiency, and uniform effective aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0046] This specific embodiment is described by taking a microwave energy receiving board with a structural working frequency of 5.8 GHz, that is, a working wavelength of about 50 mm, as an example.

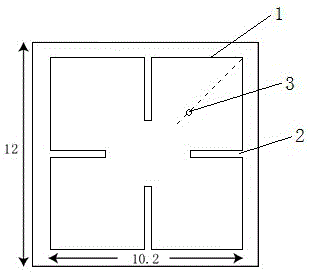

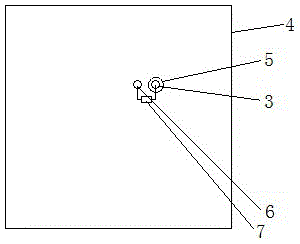

[0047] In this specific embodiment, the microwave energy receiving plate is constituted by a single sub-wavelength resonant structural unit. Such as figure 1 and figure 2 As shown, the sub-wavelength resonant structure unit is a square structure, including a sub-wavelength resonant structure and a high-frequency rectifier circuit connected to it; the high-frequency rectifier circuit includes a high-frequency rectifier chip and its auxiliary circuit; the sub-wavelength resonant structure including from top to bottom,

[0048] The top metal layer 1 is a square structure, and the middle position of each side is provided with a strip-shaped gap 2 extending to the center of the top metal layer, a total of four strip-shaped gaps; the width of the four strip-shaped gaps is equal; Th...

specific Embodiment 2

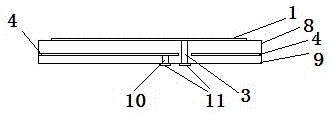

[0056] Such as image 3 As shown, similar to the specific embodiment 1, the difference is that the sub-wavelength resonant structural unit also includes an underlying insulating dielectric layer 9, and two through holes are arranged on the underlying insulating dielectric layer, one of which is connected to the positive input Corresponding to the through hole 3, the other through hole 10 is connected to the ground metal layer; two pads 11 are provided at the bottom of the bottom insulating dielectric layer, and each of the two through holes corresponds to a pad, and the high frequency rectifier through the pad The positive and negative poles of the diode are connected. Such a structure facilitates the formation of a large-area and high-efficiency microwave energy receiving plate by multiple sub-wavelength resonant structural units. In this specific embodiment, the thickness of the underlying insulating dielectric layer is 0.5 mm; the thickness of the pad is 0.035 mm.

specific Embodiment 3

[0057] Such as Figures 4 to 6 As shown, the difference from Embodiment 2 is that in this embodiment, the microwave energy receiving plate is composed of multiple sub-wavelength resonant structural units described in Embodiment 2. For each structural unit, the top metal layer The size of is smaller than the size of the whole structural unit. . Many sub-wavelength resonant structural units are periodically arranged to form a receiving board. When working, the rectifier chips on each unit will convert the radio frequency AC signals absorbed by them into DC voltages, and connect the DC voltages output by multiple units in series. The DC power supply generated by the unit is connected in series to generate a DC power supply of the required voltage to realize a high-efficiency microwave energy receiving board. When the high-efficiency wireless energy receiving board is working, the circularly polarized electromagnetic waves incident on the sub-wavelength resonant structure will g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com