Solder mask preparing method for thick copper plates

A technology of thick copper plate and solder resist, which is applied in the field of solder resist preparation of PCB boards and thick copper plates, can solve the problems of long production process and low production efficiency, and achieve significant cost reduction, process length reduction and quality improvement significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

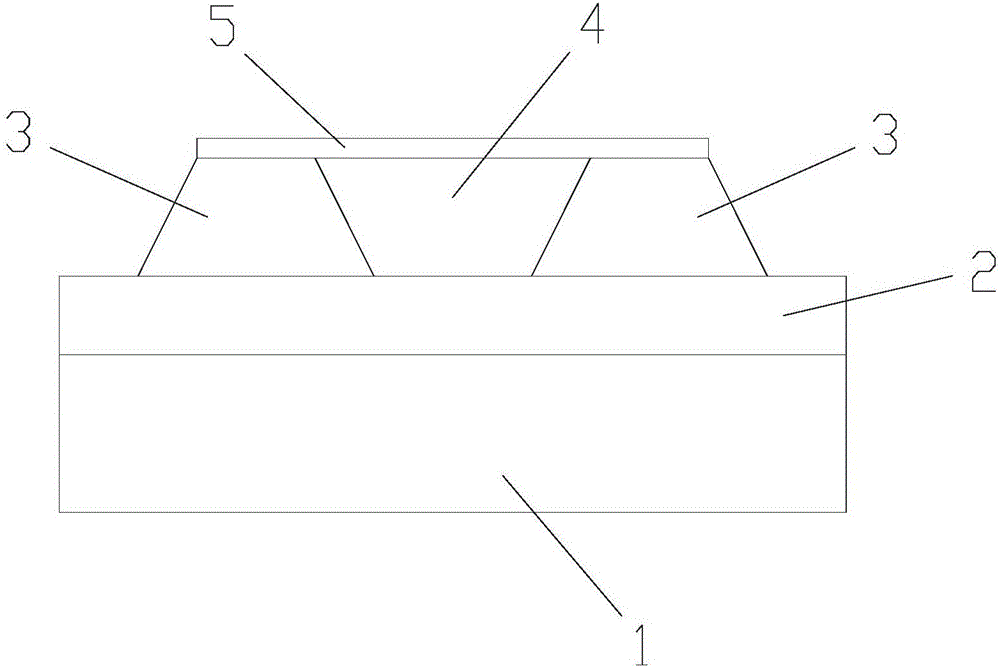

Image

Examples

Embodiment 1

[0022] In an embodiment of the present invention, a method for preparing a solder resist of a thick copper plate comprises the following steps:

[0023] A. Use mixed water brown corundum with a volume ratio of 1:5 and a particle size of 180# to spray the circuit surface of the thick copper plate, and the spray pressure is not less than 3kg / cm 2 , The speed of the whole line is 30% of the 1oz thick copper plate, to clean the surface of the thick copper plate and roughen the copper layer to ensure the quality of line processing;

[0024] B. Filling resin with optional viscosity between 160-180dpa.s, resin content of 90wt%-95wt%, and filler content of 5wt%-10wt% is used to print the circuit layer of the thick copper plate with a conventional 18T inclined screen filling;

[0025] C. After vacuuming for 0.5H, place the thick copper plate at 150°C and bake for 15 minutes to cure the filling resin;

[0026] D. Use 500# non-woven cloth brush to eliminate glue overflow on the circuit...

Embodiment 2

[0029] In an embodiment of the present invention, a method for preparing a solder resist of a thick copper plate comprises the following steps:

[0030] A. Use mixed water brown corundum with a volume ratio of 1:5 and a particle size of 180# to spray the circuit surface of the thick copper plate, and the spray pressure is not less than 3kg / cm 2 , The speed of the whole line is 30% of the 1oz thick copper plate, to clean the surface of the thick copper plate and roughen the copper layer to ensure the quality of line processing;

[0031] B, alternative viscosity is 160dpa.s, resin content is 90wt%, filler content is at the filling resin of 10wt%, uses conventional 18T inclined screen to print and fill the circuit layer that thick copper board obtains;

[0032] C. After vacuuming for 0.5H, place the thick copper plate at 150°C and bake for 15 minutes to cure the filling resin;

[0033] D. Use a 500# non-woven cloth brush to eliminate the glue overflow on the circuit surface on t...

Embodiment 3

[0036] In an embodiment of the present invention, a method for preparing a solder resist of a thick copper plate comprises the following steps:

[0037] A. Use mixed water brown corundum with a volume ratio of 1:5 and a particle size of 180# to spray the circuit surface of the thick copper plate, and the spray pressure is not less than 3kg / cm 2 , The speed of the whole line is 30% of the 1oz thick copper plate, to clean the surface of the thick copper plate and roughen the copper layer to ensure the quality of line processing;

[0038] B, alternative viscosity between 180dpa.s, resin content of 95wt%, filler content of 10wt% filling resin, use conventional 18T inclined screen to print and fill the circuit layer obtained from the thick copper plate;

[0039] C. After vacuuming for 0.5H, place the thick copper plate at 150°C and bake for 15 minutes to cure the filling resin;

[0040] D. Use a 500# non-woven cloth brush to eliminate the glue overflow on the circuit surface on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com