Drive device for electric vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

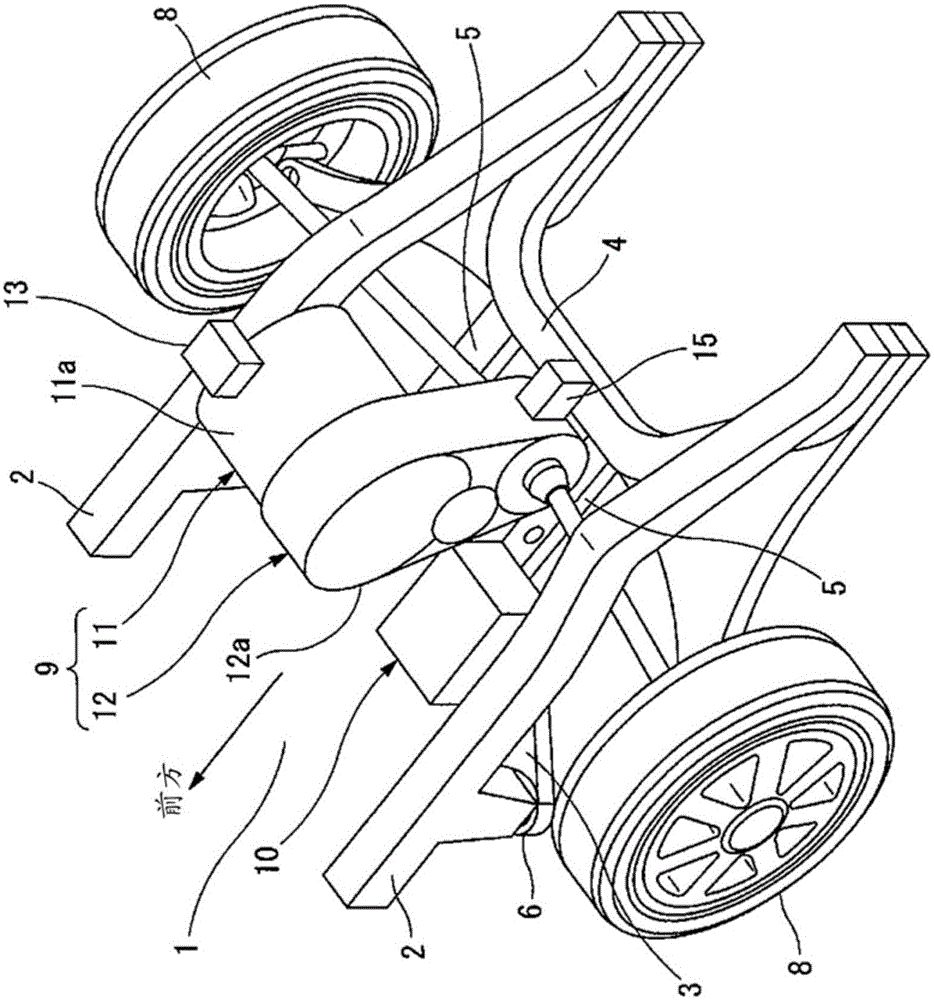

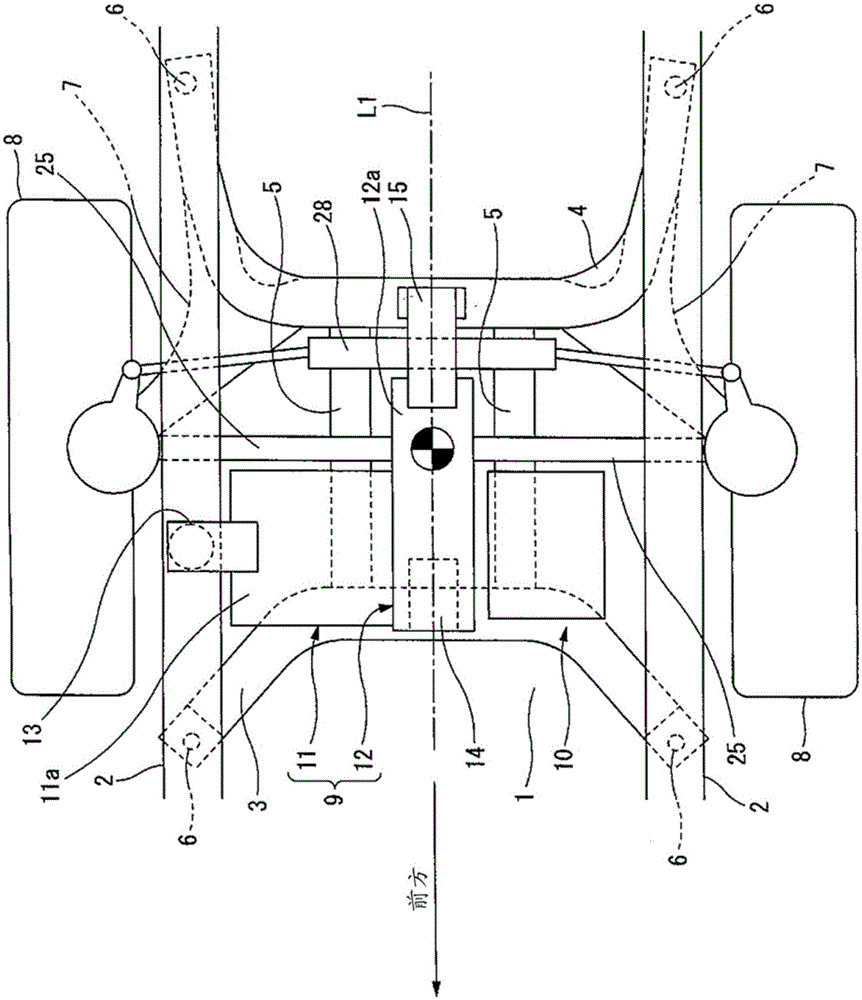

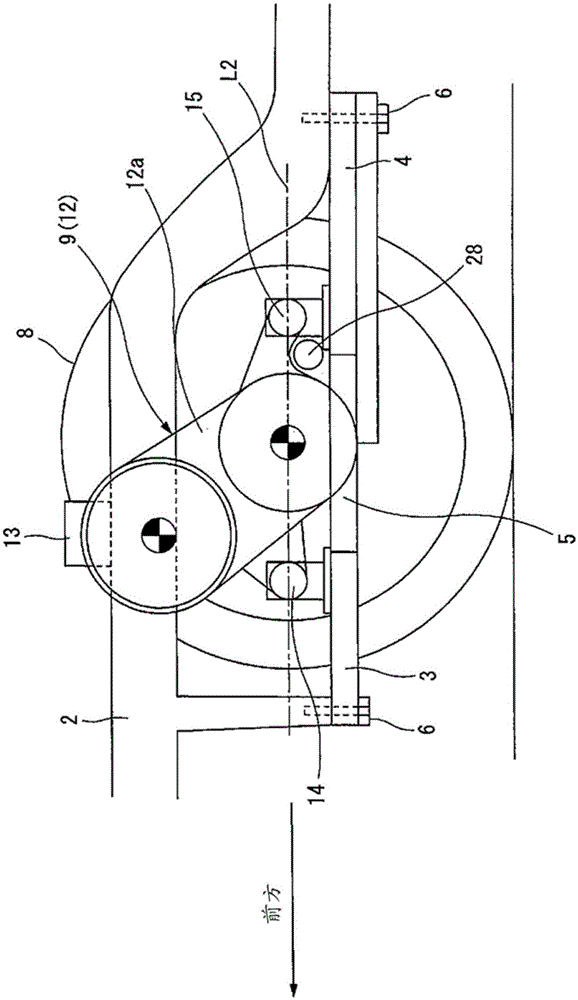

[0017] Figure 1 to Figure 5 A more specific first embodiment of the drive device for an electric vehicle for carrying out the present invention is shown, in particular, figure 1 It shows the schematic layout of the electric motor power unit as the driving device in the electric motor room of the front-wheel-drive electric vehicle. in addition, figure 2 yes figure 1 top view illustration of figure 2 yes figure 1 The side view explanatory drawing of , in addition, image 3 means from figure 1 An explanatory diagram of the front view of the front view.

[0018] remove figure 1 other than Figure 2 ~ Figure 4 As shown, in the motor room 1 at the front of the vehicle body, a pair of left and right side members 2 as strength members extending in parallel to the front of the vehicle and forming the skeleton of the motor room 1, as shown in FIG. figure 2 As shown, a pair of suspension members 3 and 4 independent in front and rear are arranged on the lower side of the pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com