Mechanical seal arrangement having sliding surfaces of differing hardness

A technology of mechanical seals and sliding surfaces, applied in mechanical equipment, engine seals, engine components, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

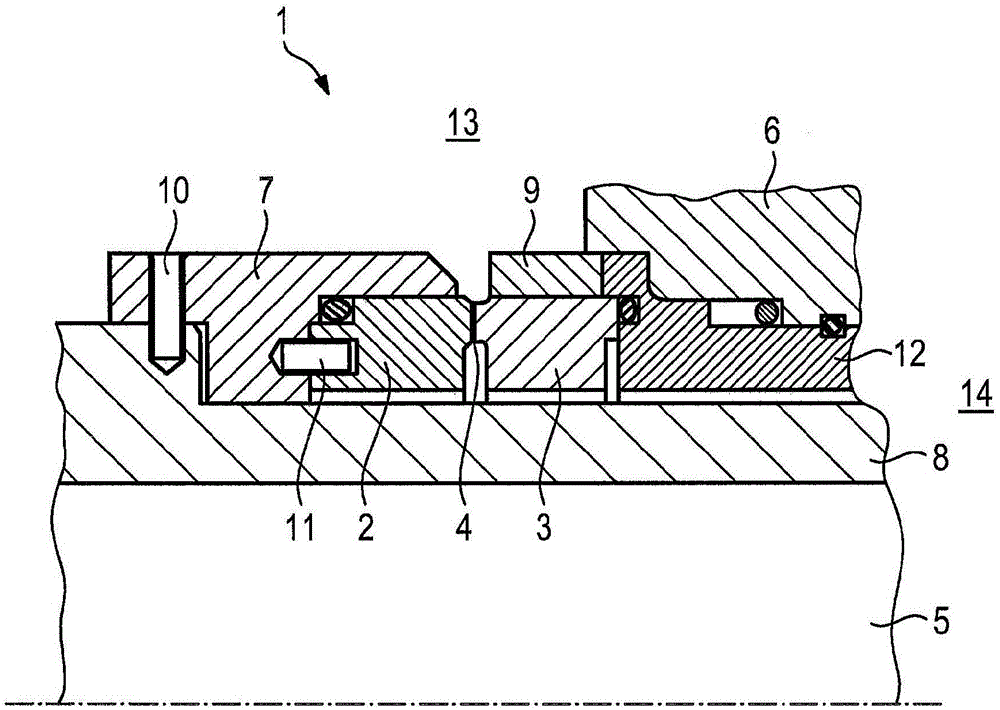

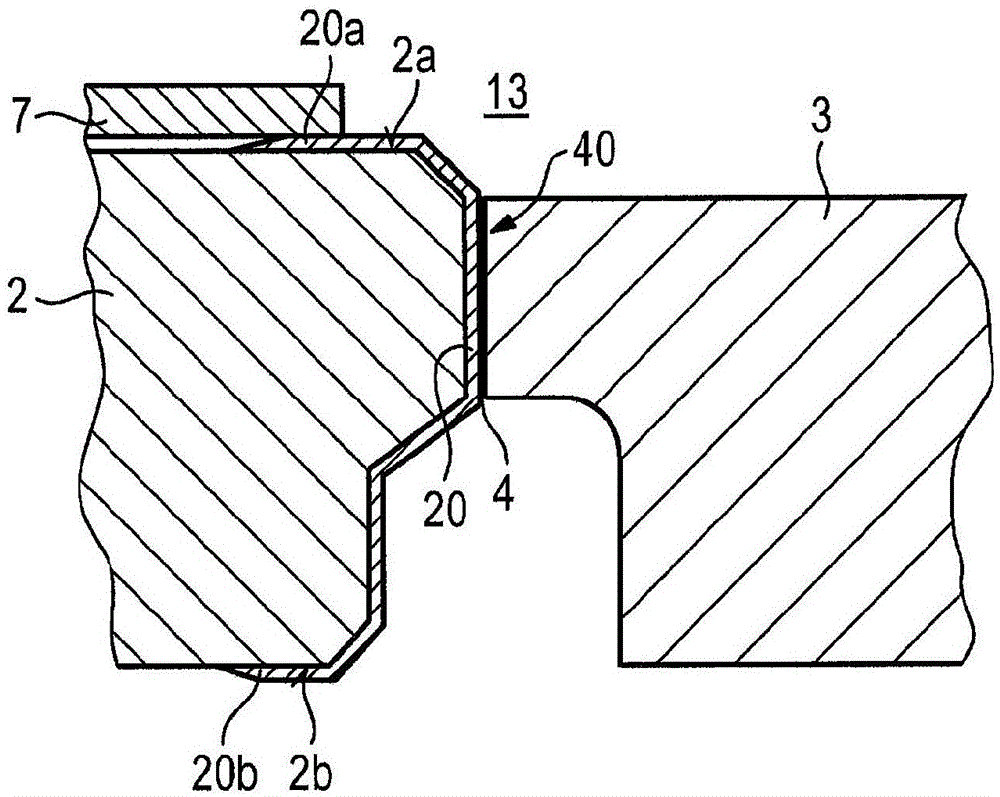

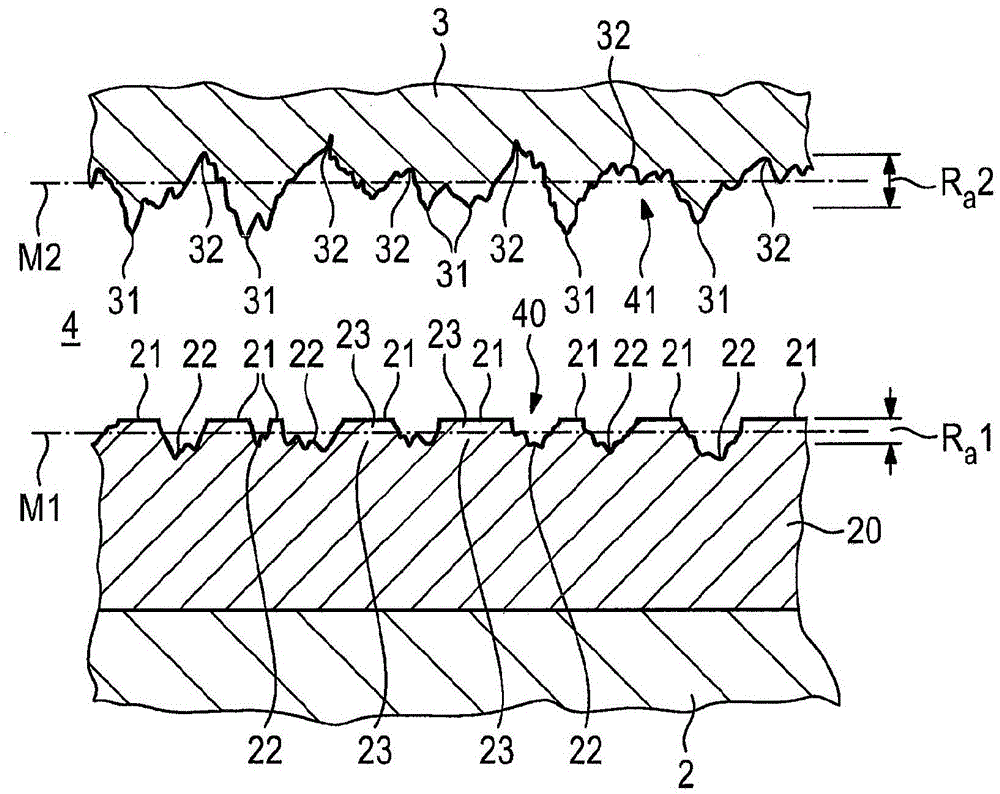

[0024] Refer to the following Figure 1 to Figure 3 A mechanical seal device 1 according to a preferred exemplary embodiment of the present invention is explained in detail.

[0025] figure 1 A mechanical seal device 1 for a power station feed pump is schematically shown, and the mechanical seal device 1 includes a rotating slip ring 2 and a stationary slip ring 3 . A sealing gap 4 is formed between the two slide rings 2 , 3 in a known manner. The rotary slip ring 2 is connected to a shaft bushing 8 via a rotary support ring 7 . The first pin 10 and the second pin 11 are provided for rotation and for torque transmission. The shaft bush 8 is disposed on the rotary shaft 5 .

[0026] The fixed slip ring 3 has a joint 9 fixed to the housing 6 via a fixed support ring 12 .

[0027] The mechanical seal 1 thus seals off the medium 13 to be conveyed by the power station supply pump from the environment 14 . The medium 13 in this exemplary embodiment is pure water. The low cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com