Degradable, flame-retarded and anti-bacterial surgical gown and making method thereof

A manufacturing method and technology of surgical gowns, which are applied in the field of flame-retardant, degradable, and antibacterial surgical gowns, can solve the problems of not mentioning the specific components of flame-retardant powder, unfavorable disposal of waste non-woven fabrics, and the use of materials that are difficult to degrade, etc., to achieve Improve the ventilation effect, protect the health of the body, and have the effect of strong degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

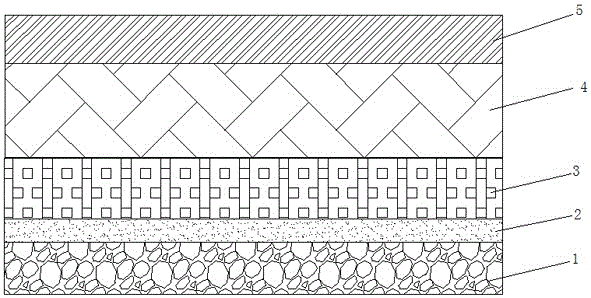

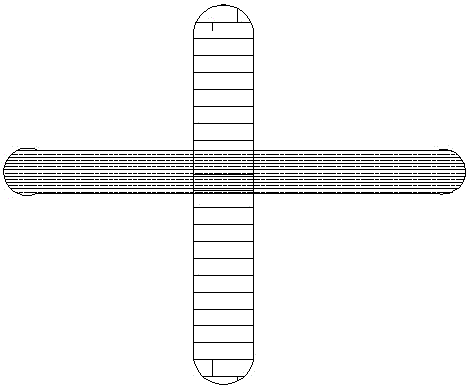

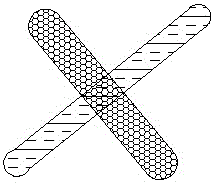

[0028] see Figure 1 ~ Figure 3 , a degradable, flame-retardant, antibacterial surgical gown according to the present invention, the surgical gown is made of degradable, flame-retardant, antibacterial non-woven fabric, the non-woven fabric includes: sequentially glued from bottom to top The first base fabric layer 1, the heat insulation layer 2, the waterproof layer 3, the antibacterial layer 4 and the second base fabric layer 5; the first base fabric layer 1 is melted and sprayed by polyhydroxybutyrate and polylactic acid The formed composite fibers are arranged in a criss-cross arrangement; the second base fabric layer 5 is formed by criss-cross arrangement of composite fibers formed by melting and spinning polypropylene and polyethylene terephthalate; the first base layer Several through holes (not shown) are opened on the surface of the cloth layer 1 and the second base cloth layer 5 respectively, the opening ratio is 90-95%, and the hole diameter is 0.1-0.2 mm.

[0029] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com