Automatic hot melt type twisted-pair stimulation electrode manufacturing device

A technology for stimulating electrodes and preparing devices, which is applied in the direction of electrodes and metal processing, etc., to achieve the effects of convenient operation, high yield and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

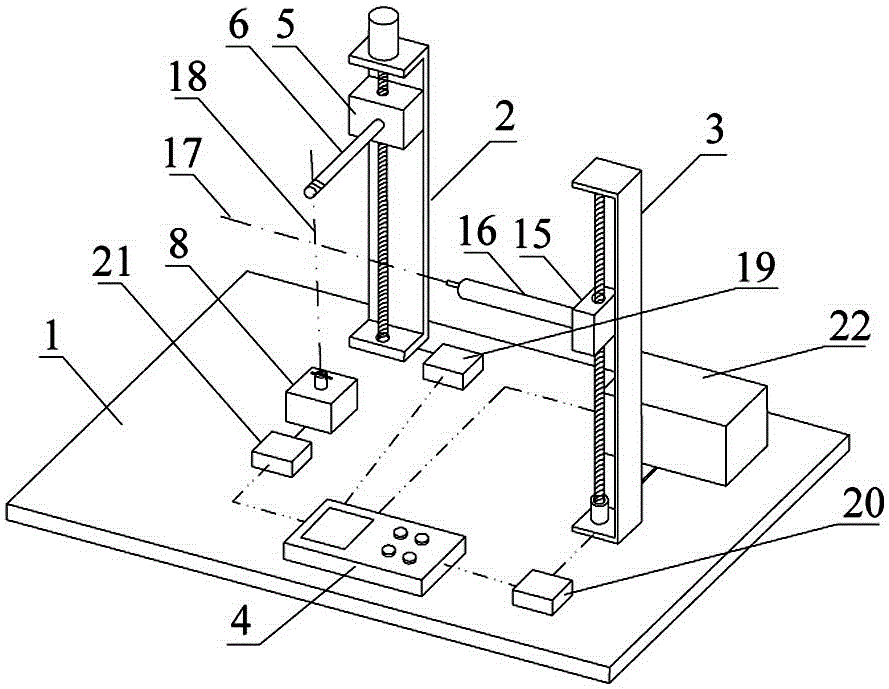

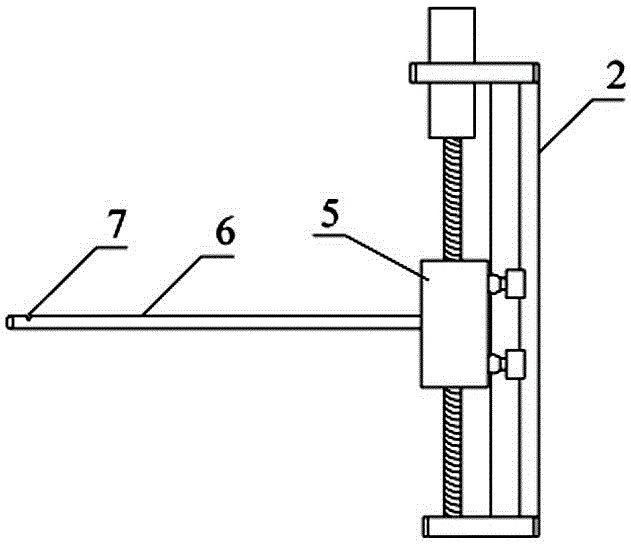

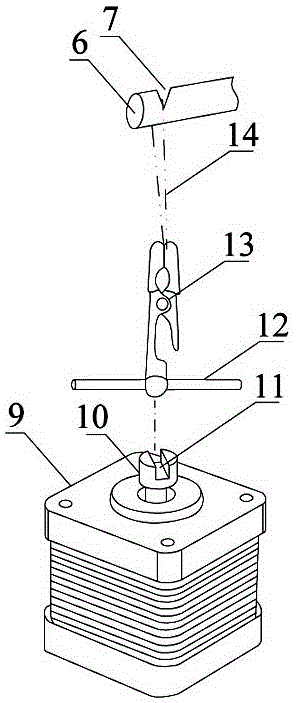

[0024] Such as figure 1 As shown, the automatic hot-melt twisted pair stimulating electrode preparation device of the present invention includes the first linear guide pair 2, the second linear guide pair 3 and the microcontroller 4 vertically fixed on the base plate 1, and the dual Stranded wire stimulating electrode assembly; e.g. figure 1 , 2 As shown, the slider 5 of the first linear guide rail pair 2 is horizontally fixed with an electrode wire support rod 6, and the front end of the electrode wire support rod 6 is provided with an upper opening hanging groove 7 of a V-shaped structure, which is located at the front of the upper opening hanging groove 7. A twisting device 8 is arranged on the bottom plate 1 below. Such as image 3 As shown, the twisting device 8 includes a stepper motor 9 arranged vertically upward, the power shaft end of the stepper motor 9 is provided with a coupling 10 made of magnetic material, and the upper end surface of the coupling 10 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com