Multi-point laser welding clamping device for battery pack busbar

A technology of laser welding and busbar, which is applied in the direction of laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of unsatisfactory welding firmness, easy oxidation and blackening of solder joints, and reduced work efficiency, so as to achieve convenient control and prevent Oxidation and blackening, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

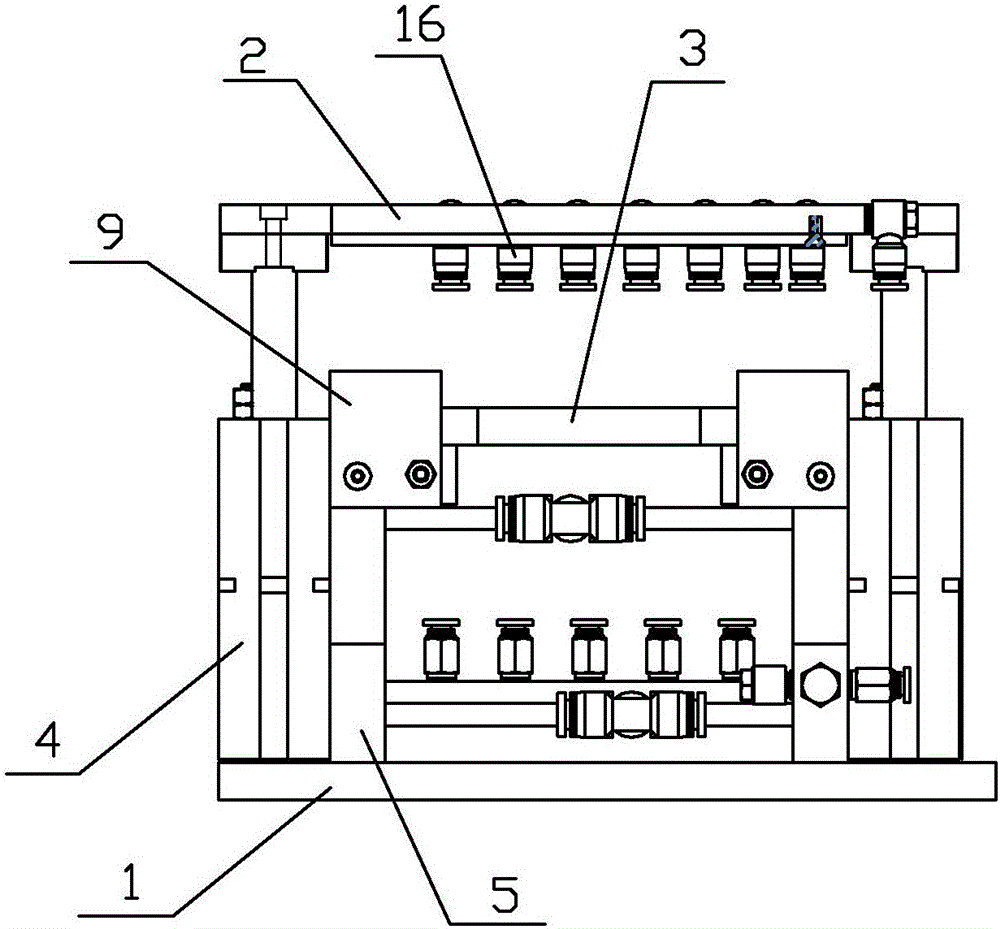

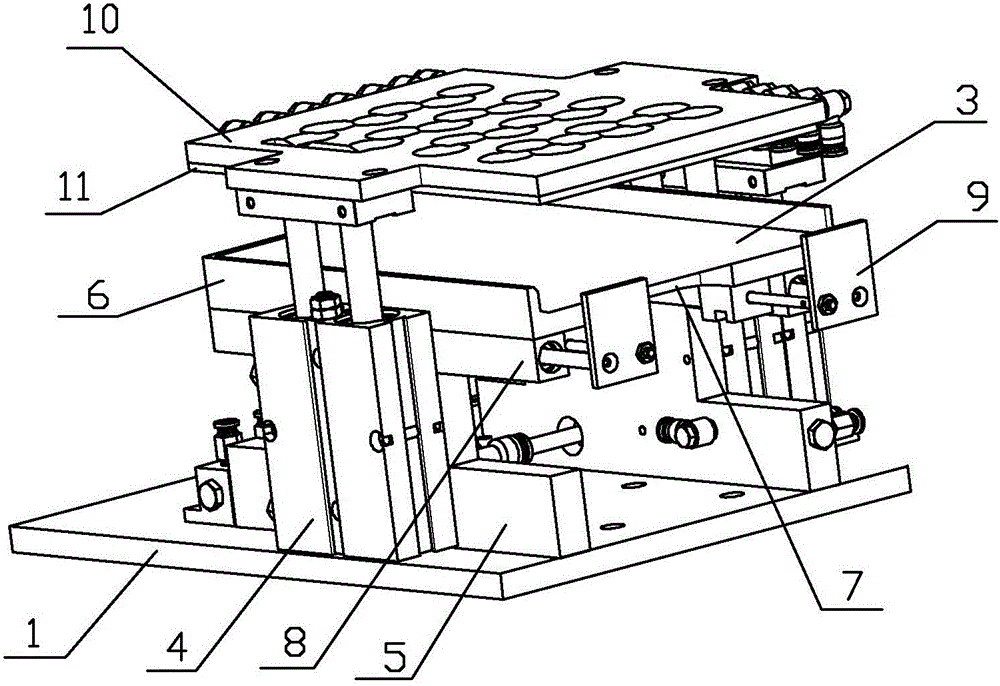

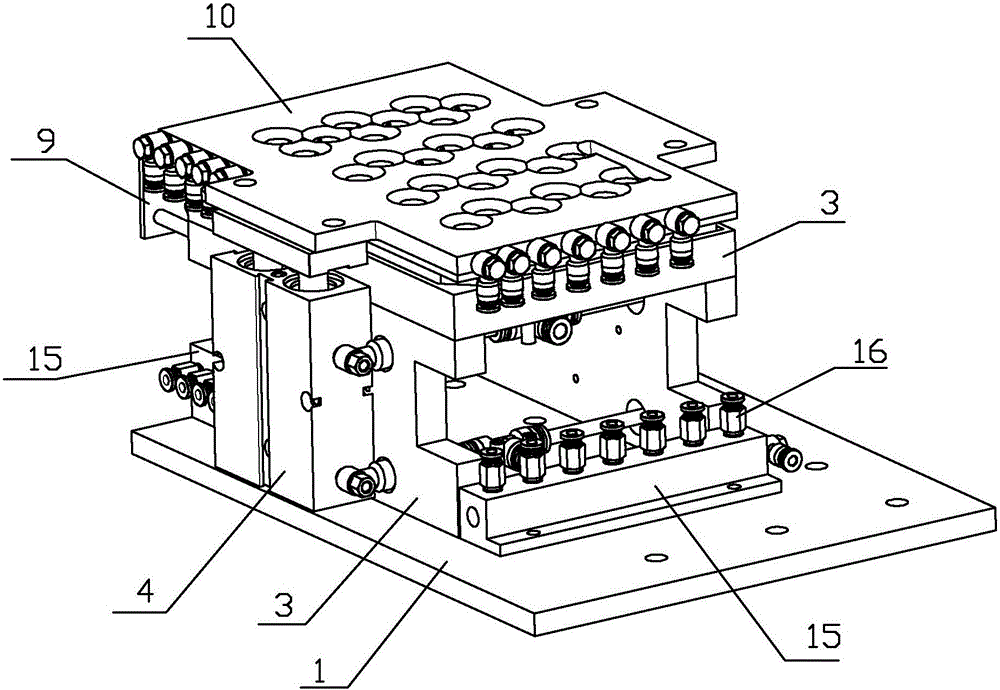

[0026] Embodiment 1: The battery pack busbar laser welding multi-point welding clamping device of this embodiment, such as figure 1 , image 3 As shown, including the base plate 1, the upper splint 2 and the lower splint, a vertical cylinder 4 and a support plate 5 are installed on the left and right sides of the base plate 1, and the support plate 5 is close to the inner side of the vertical cylinder 4 and is connected with the vertical cylinder The two vertical cylinders are connected through pipelines and air pipe joints and connected with high-pressure air pipes. The left side and right side of the lower splint are respectively installed on two support plates 5, and the left side and right side of the upper splint 2 are respectively installed on two 4 vertical cylinders. Such as figure 2 As shown, the lower splint is a pallet 3, the left side, the right side and the rear side of the pallet 3 are connected with an upward surrounding edge 6, and there is a gap 7 in the midd...

Embodiment 2

[0028] Embodiment 2: The battery pack busbar laser welding multi-point welding clamping device of this embodiment, such as Figure 8 As shown, two sets of battery pack busbar laser welding multi-point welding clamping devices with the same structure are installed on the bottom plate 1, and the structure of each battery pack busbar laser welding multi-point welding clamping device is the same as that of embodiment 1, two The battery pack bus bar laser welding multi-point welding clamping device is arranged adjacent to the left and right, and the vertical cylinders 4 on the two battery pack bus bar laser welding multi-point welding clamping devices are connected to the high-pressure air pipe through their own independent control valves, that is, the high-pressure air pipe It is connected to the vertical cylinder of the clamping device on the left through a control valve, and the high-pressure air pipe is connected to the vertical cylinder of the clamping device on the right throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com