Method and apparatus for casting concrete products

A technology for pouring concrete and concrete products, applied in program control, manufacturing tools, comprehensive factory control, etc., can solve problems affecting efficiency and achieve rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

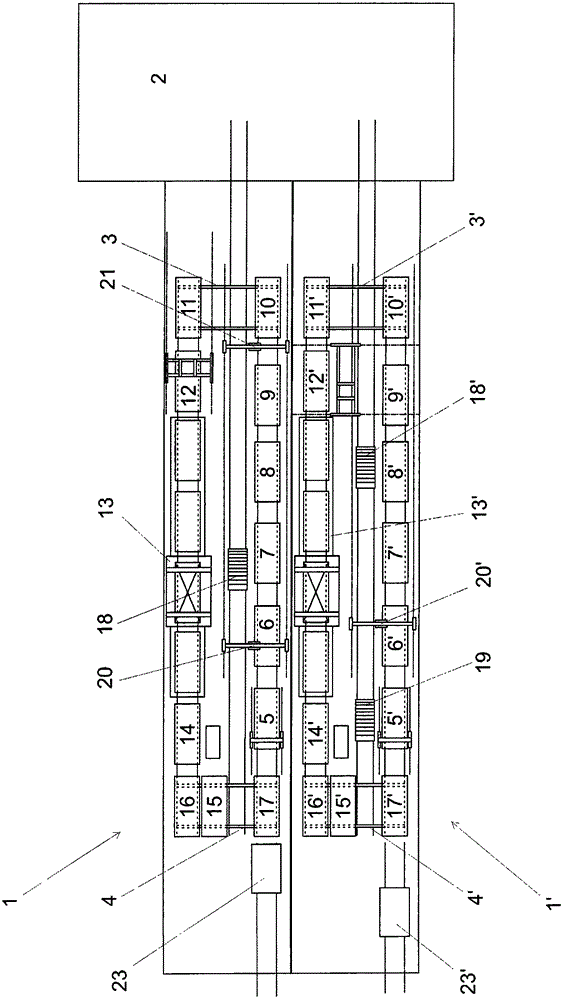

[0023] figure 1 The layout of the manufacturing plant is schematically shown, which includes two circulation line casting processes 1, 1' and a reinforcement workshop 2.

[0024] The circular line pouring process 1, 1' comprises a plurality of work sections or stations which are located side by side along the length of the process in two separate work station lines on transverse transfer tracks located at the ends of the work station line 3,3' and 4,4' are connected together. The mold tables or molds are transferred from one workstation to another along rails extending along the workstation lines, and from one workstation line to another via transverse transfer rails 3, 3' and 4, 4'.

[0025] In the pouring process 1, 1' of the circular line, the first work stage carried out in the first work station 5, 5' is the cleaning of the mold table, after which the mold table is moved to the feeding stage, the side walls of the mold are in Here it is fixed to the mold table so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com