Commuting airplane fuel oil ventilation device

A ventilation device and aircraft technology, which is applied to the power plant, aircraft parts, fuel supply of the power plant and other directions on the aircraft, can solve the problems of different opening positions and forms, and achieve the effect of simplifying the design process, reducing the design cost, and avoiding the test link.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

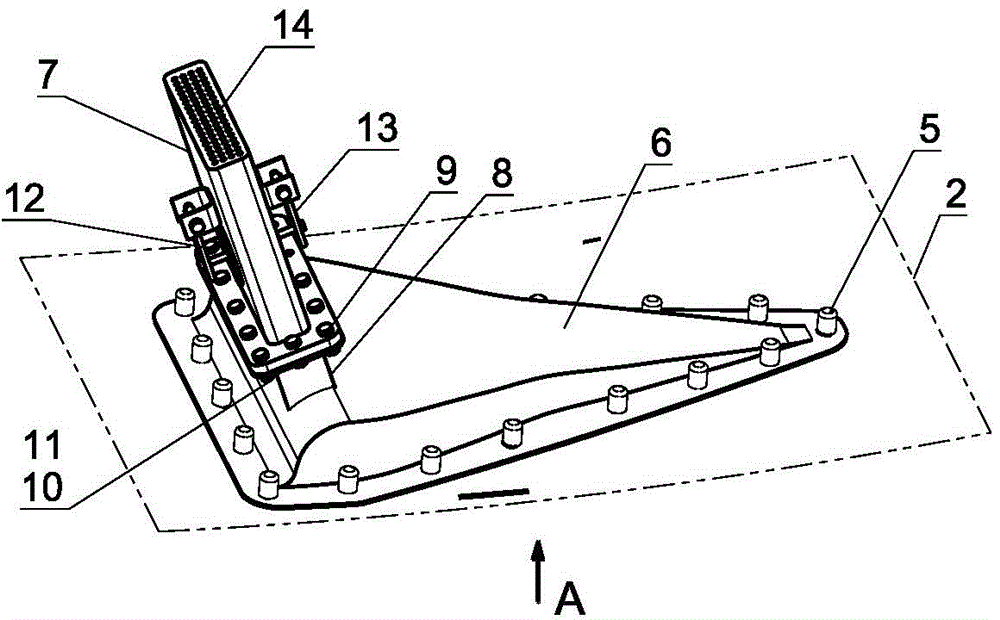

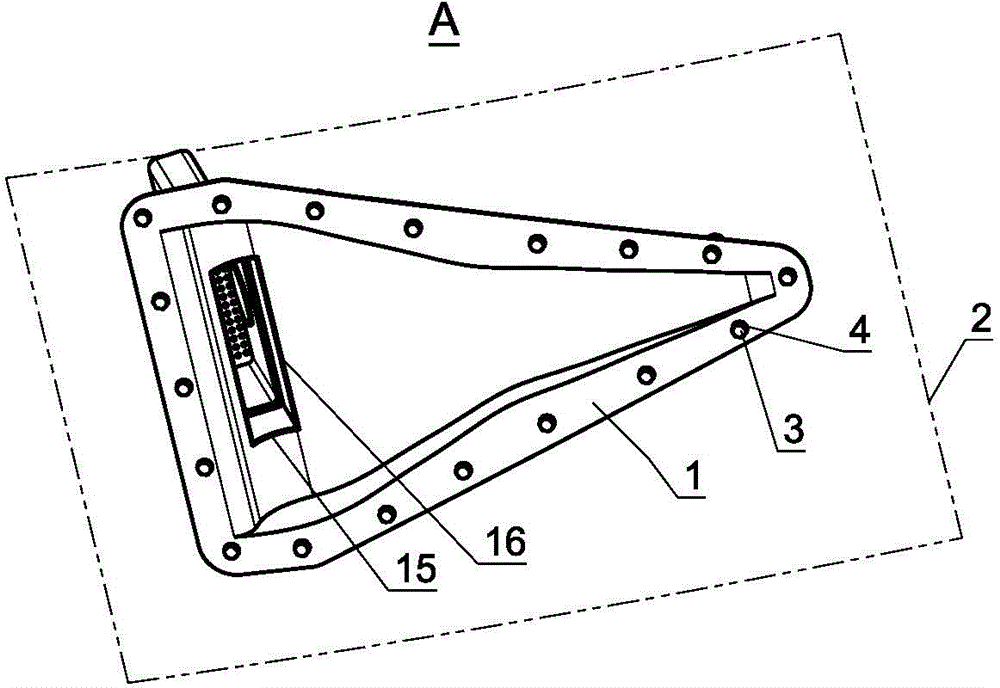

[0015] A commuter aircraft fuel ventilation device, in which, the embedded vent 1 is located on the lower wing surface of the fuel tank ventilation compartment, and the buried vent 1 is a bulge with a wedge-shaped slope, and the tip of the wedge-shaped slope is on the At the front of the course, the height of the tip of the wedge-shaped slope is flush with the airfoil, and the wide end of the wedge-shaped slope is at the rear of the course. The height of the wide end of the wedge-shaped slope makes the angle between the wedge-shaped slope and the airfoil 7°-9° The upper surface of the wide end of the wedge-shaped slope is equipped with a vent pipe 8, and the flame suppressor 7 is fixed on the vent pipe of the buried vent 1 through screws 9, nuts, gaskets 10 and rubber gaskets or sealants 11 8 on. The cross section of the vent pipe 8 is a rectangle with an aspect ratio of 4:1-3:1, and the length of the cross section of the vent pipe 8 is 0.5-0.6 of the width of the wide end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap