A kind of viscosity stabilizer and its application

A viscosity stabilizer and cross-linking agent technology, applied in the field of viscosity stabilizers, can solve the problems of affecting the oil displacement effect, unsatisfactory effect, viscosity loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]The viscosity stabilizer is: 10wt% of mercaptobenzothiazole sodium, 2wt% of epoxypropylmethyl diethoxysilane, 5wt% of metal ion complexing agent ethylenediamine tetramethylene phosphonate sodium and the rest of water.

[0055] The experimental polymer selects polyacrylamide (HPAM, 3640C of France Eisen Company), and the salinity of the simulated water used for preparation is 7000mg / L (wherein Ca 2+ with Mg 2+ The sum of the concentrations is 50mg / L), and the polymer concentration obtained by using the above-mentioned raw materials to prepare is 2000mg / L.

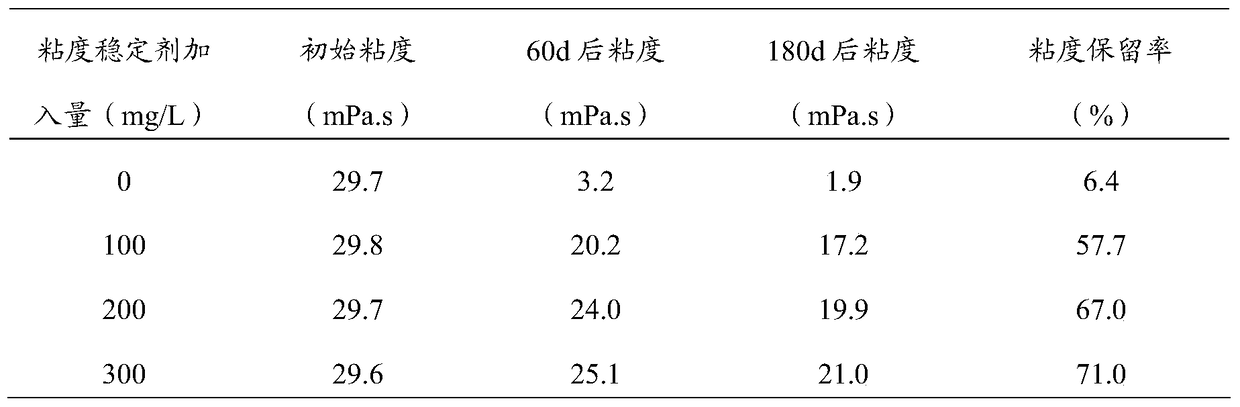

[0056] Add the viscosity stabilizer into the polymer solution in the amount of 100-300 mg / L as shown in Table 1, and test its viscosity after constant temperature at 85°C for 180 days. The results are shown in Table 1.

[0057] Table 1 embodiment 1 viscosity test result

[0058]

[0059] It can be seen from Table 1 that, compared with the blank polymer solution without adding a viscosity stabilizer, the addition o...

Embodiment 2

[0061] The viscosity stabilizer is: 10wt% of mercaptobenzothiazole sodium, 5wt% of glycidyltrimethoxysilane, 4wt% of metal ion complexing agent sorbitol and the rest of water.

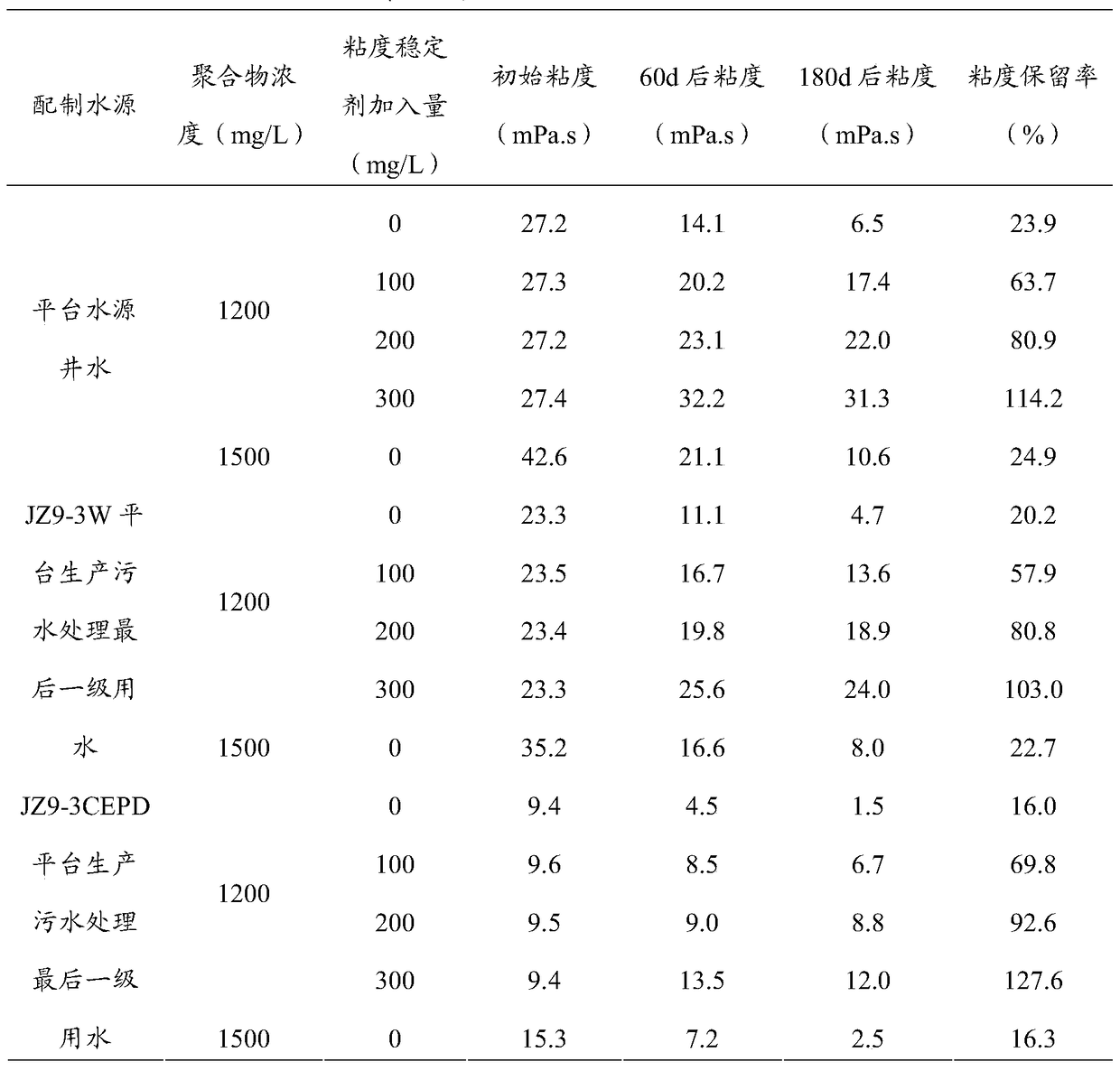

[0062] The experimental polymer polyacrylamide (HPAM, 3640C from France Eisen Company), the preparation water is respectively platform water source well water, JZ9-3W platform production sewage treatment final stage water and JZ9-3CEPD platform production sewage treatment final stage water; The above-mentioned raw materials are respectively configured into 1200mg / L and 1500mg / L polymer solutions.

[0063] Add the viscosity stabilizer into the polymer solution in the amount of 100-300 mg / L as shown in Table 2, and test its viscosity after constant temperature at 57°C for 180 days. The results are shown in Table 2.

[0064] Table 2 embodiment 2 viscosity test result

[0065]

[0066] It can be seen from Table 2 that the polymer solution with a concentration of 1200mg / L prepared by the platform water ...

Embodiment 3

[0068] The viscosity stabilizer is: 12wt% of mercaptobenzothiazole sodium, 2.5wt% of epoxypropylmethyldiethoxysilane, 4wt% of heptasodium diethylenetriamine pentamethylene phosphonate, and the balance of water.

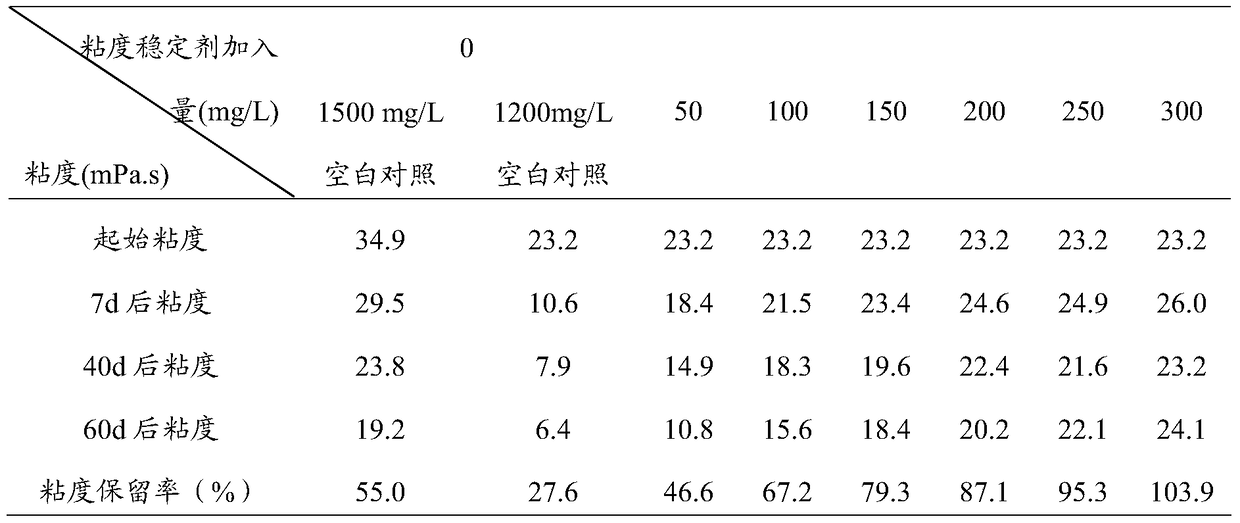

[0069] Add 5mg / L of Fe in the source well water of the platform 2+ , use it to prepare polyacrylamide polymer (HPAM, France Eisen 3640C) solution concentration is 1200mg / L and 1500mg / L respectively.

[0070] Add the viscosity stabilizer to the 1200mg / L polymer solution according to the dosage in Table 3, and use the 1500mg / L polymer solution as a blank control, place it in an oven at 60°C, and test its viscosity. The results are shown in Table 3.

[0071] Table 3 embodiment 3 viscosity test result

[0072]

[0073] It can be seen from Table 3 that the viscosity retention rate of the polymer solution with a concentration of 1200mg / L has been greatly improved after adding the viscosity stabilizer. After the addition of the viscosity stabilizer is greater than 100mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com