Natural gas dehydration unit

A dehydration device and natural gas technology, applied in the direction of gas fuel, dispersed particle filtration, petroleum industry, etc., can solve the problems of low dehydration efficiency and inability to dehydrate, and achieve the effect of preventing waste, not easy to freeze, and preventing dirt from clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

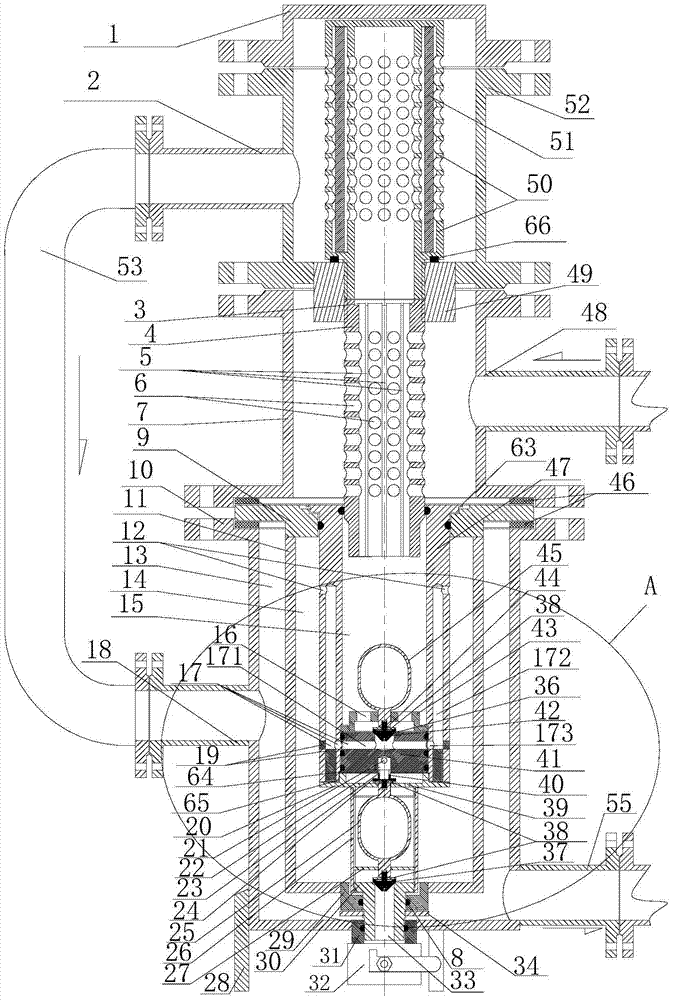

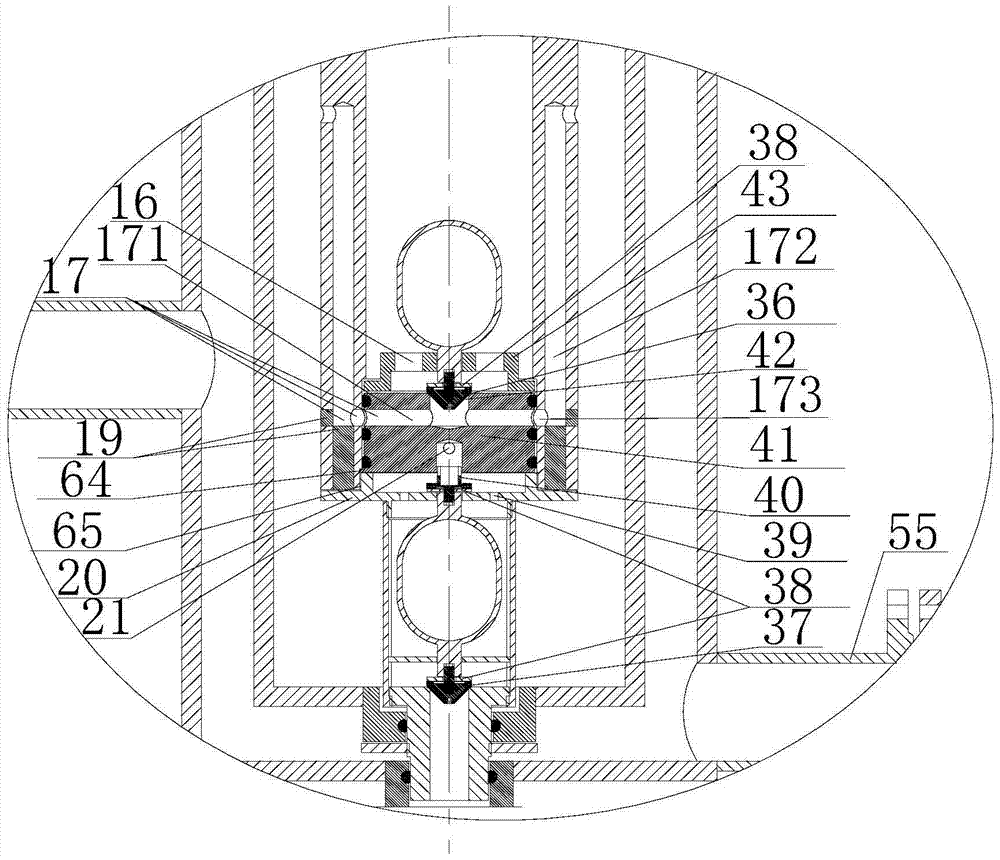

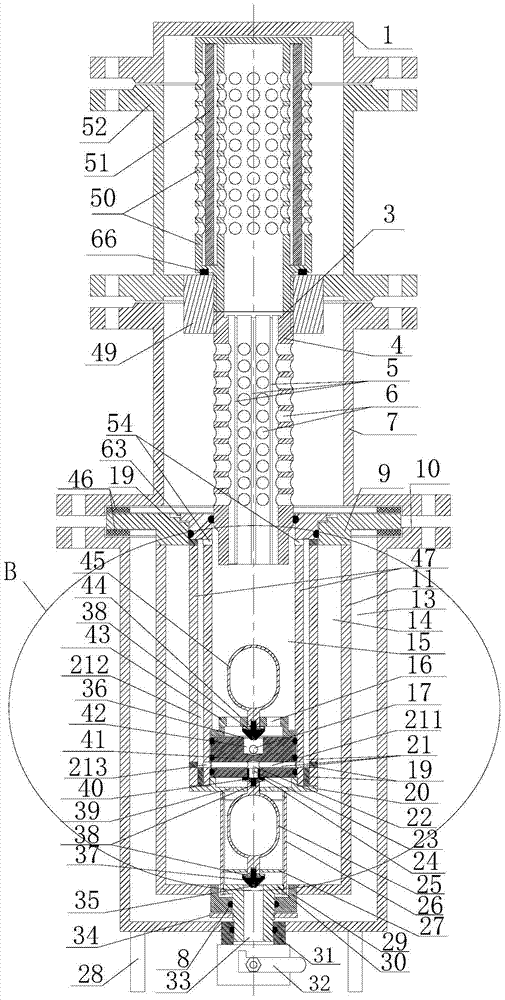

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0041] Such as Figure 1 to Figure 4 As shown, the present invention provides a natural gas dehydration device for dehydrating wet natural gas, wherein wet natural gas or wet gas refers to natural gas containing water vapor, or in oil production stations, when the temperature is below zero, the gas The natural gas that can be frozen in the pipeline is called wet natural gas or wet gas, and the natural gas that does not freeze is called dry natural gas or dry gas. The natural gas dehydration device includes a dehydration unit for dehydration and a drainage unit for drainage.

[0042] Wherein, the dehydration part comprises a first cylinder body 7 and a second cylinder body 52 sealingly connected above the first cylinder body 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com