A rapid screening method for non-starch polysaccharide zymogram of pig feed

A non-starch polysaccharide enzyme and non-starch polysaccharide technology, which is applied in the field of rapid screening of non-starch polysaccharide zymograms in pig feed, can solve the problems of systematic errors and accidental errors, many factors, lack, cost, etc., and achieve rapid optimization of non-starch polysaccharides Zymogram, Efficacy Enhancement, Overcoming Blindness Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

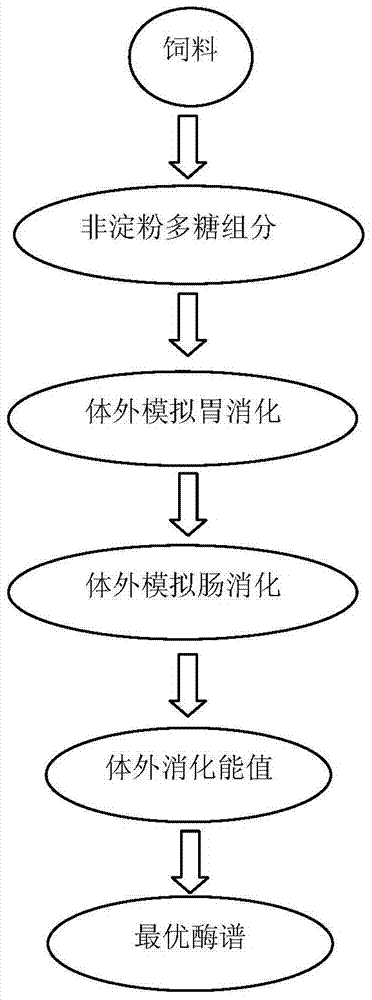

[0021] Such as figure 1 As shown, the specific implementation method of the present invention can be implemented in the following manner:

[0022] Select corn-soybean meal-type compound feed and put it into a pulverizer, wherein the feed includes corn-soybean meal-type compound feed and corn and soybean meal raw materials that make up the compound feed; then control the speed of the pulverizer at 8000-10000 rpm per minute, and the crushing time is 5 to 10 minutes; pass the crushed feed through a 0.25 to 0.42 mm sieve; accurately weigh 100 to 250 mg of feed sample, and measure the content of non-starch polysaccharide components in compound feed and feed raw materials;

[0023] According to the non-starch polysaccharide components of the compound feed and feed raw materials, according to the results of principal component analysis, weigh 1 to 2 grams of corn-soybean meal compound feed, and add three kinds of non-starch polysaccharide enzymes, i.e. wood Glycanase, cellulase, β-g...

Embodiment 2

[0030] Select the wheat-soybean meal type compound feed and put it into a micro pulverizer, wherein the feed includes wheat-soybean meal type compound feed and the wheat and soybean meal raw materials that make up the compound feed; then control the speed of the micro pulverizer at 8000~ 10,000 rpm, crushing time is 5-10 minutes; pass the crushed feed through a 0.25-0.42 mm sieve; accurately weigh 100-250 mg of feed sample, and measure the content of non-starch polysaccharide components in compound feed and feed raw materials;

[0031] According to the non-starch polysaccharide components of the compound feed and feed raw materials, according to the results of principal component analysis, weigh 1 to 2 grams of wheat-soybean meal compound feed, and add four kinds of non-starch polysaccharide enzymes in the feed, namely wood Glycanase, cellulase, β-glucanase, pectinase, the concentration gradient levels of each non-starch polysaccharide enzyme additive were set to 0, 100, 200, 3...

Embodiment 3

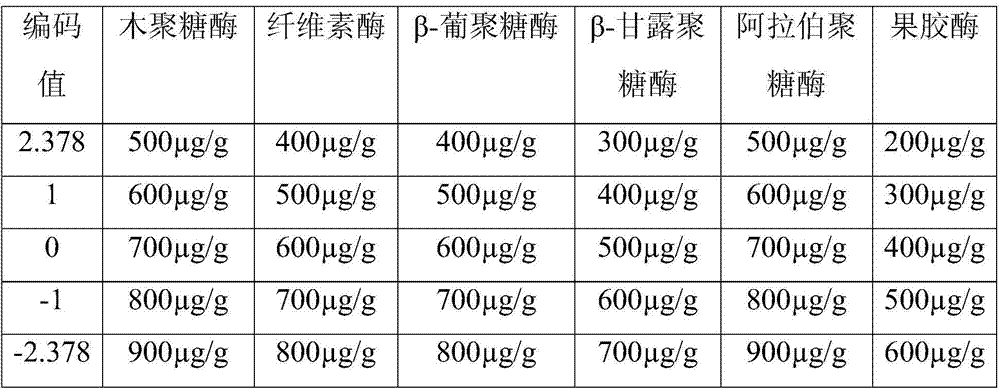

[0038] (1) Choose a corn-soybean meal-cotton meal-rape meal ration, and add six kinds of non-starch polysaccharases, namely xylanase, cellulase, β-glucanase, β-mannose, respectively, to the feed Glycanase, arabinanase and pectinase, the concentration gradient levels of each non-starch polysaccharide enzyme additive were set to 0, 100, 200, 300, 400, 500, 600, 700, 800, 900 μg / g, Prepared a series of corn-soybean meal-cotton meal-rape meal type diets added with different concentrations of non-starch polysaccharidase;

[0039] Select corn-soybean meal-cotton meal-rape meal type compound feed and put it into the pulverizer, wherein said feed comprises corn-soybean meal-cotton meal-rape meal type compound feed and the corn, soybean meal, cotton meal, rapeseed meal that make up the compound feed Meal raw material; then control the speed of the micro pulverizer at 8,000 to 10,000 rpm, and the pulverization time is 5 to 10 minutes; pass the pulverized feed through a 0.25 to 0.42 mm s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com