Preparation method of anti-sinking material in body armor

An anti-sag, bulletproof vest technology, used in protective equipment, offensive equipment, personnel protection equipment and other directions, can solve the problem of the heavy weight of the buffer layer PC board and lack of ballistic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of aramid anti-sag material

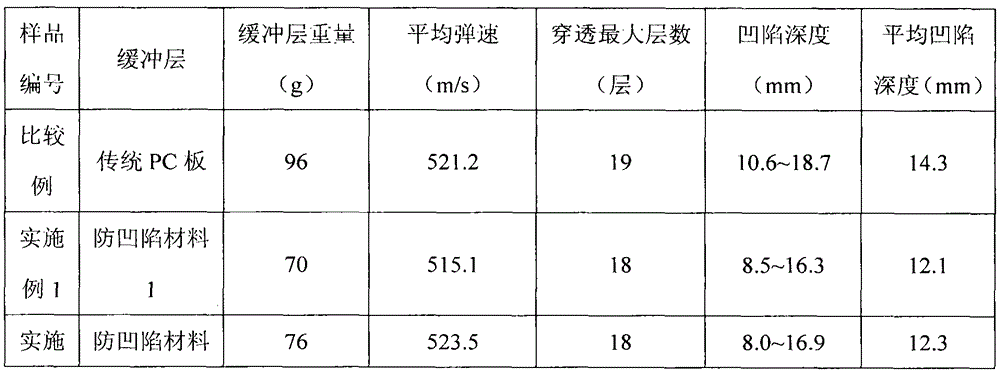

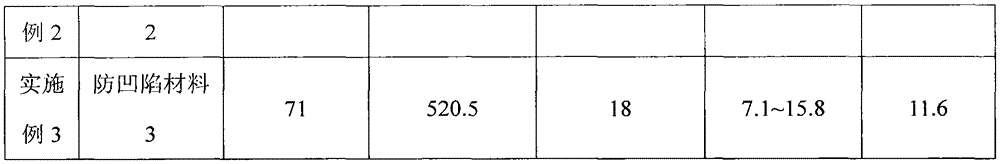

[0015] Prepare 1000g of water-based epoxy resin adhesive with a solid content of 30%, add 30g of triethanolamine curing agent, stir evenly, and put it into the glue tank; the aramid fiber is obtained through the glue tank, yarn spreading and drying process [0° / 90° [0 ° / 90°, 0° / 90°] in the press molding machine, the pressure is 5MPa, the temperature is 100°C, the pressing time is 15min, and finally the sample is cold pressed in the normal temperature press molding machine for 20min, The sample taken out is the anti-sag material 1, and the bulletproof test is carried out on this material. The results are shown in Table 1.

Embodiment 2

[0017] Preparation of aramid anti-sag material

[0018] Prepare 1000g of water-based polyurethane adhesive with a solid content of 40%, add 20g of isocyanate curing agent, stir evenly, and put it into the glue tank; the aramid fiber is made of [0° / 90°] double Laminated aramid non-weft fabric; remove the backing film from the woven aramid non-weft fabric, cut into several pieces of 40cm×40cm sheet-like non-weft fabric, select 2 layers of sheet-like non-weft fabric, and use [0° / 90 °, 0° / 90°] in the press molding machine, the pressure is 5MPa, the temperature is 120°C, and the pressing time is 15min. Finally, the sample is cold-pressed in the normal temperature pressure molding machine for 20min, and the sample is taken out. That is, the anti-sag material 2, the bullet resistance test was carried out on this material, and the results are shown in Table 1.

Embodiment 3

[0020] Preparation of aramid anti-sag material

[0021] The water-based epoxy resin and water-based polyurethane adhesive were prepared in a ratio of 2:1 to prepare 1000 g of an adhesive with a solid content of 35%, add 15 g of triethanolamine curing agent, stir evenly, and put it into the glue tank; [0° / 90°] double-layered aramid non-woven fabric was obtained in the drying process; the woven aramid non-woven fabric was removed from the bottom film, and cut into a number of sheet-like non-woven fabrics of 40cm×40cm, and 2 The layered non-woven fabric is placed in a press molding machine in the manner of [0° / 90°, 0° / 90°], the pressure is 7MPa, the temperature is 120°C, and the pressing time is 15min. Finally, the sample is placed at room temperature. After 20 minutes of cold pressing in the pressure molding machine, the sample taken out is the anti-sag material 3, and the bullet resistance test is carried out on this material. The results are shown in Table 1.

[0022] The ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com