Washing machine water recycling treatment module and washing machine

A washing machine and water treatment technology, which is applied to other washing machines, washing machine control devices, applications, etc., can solve the problems of inability to recycle laundry water, cannot be used, and high cost of use, and achieve suitable promotion and use, convenient production and assembly, and a wide range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

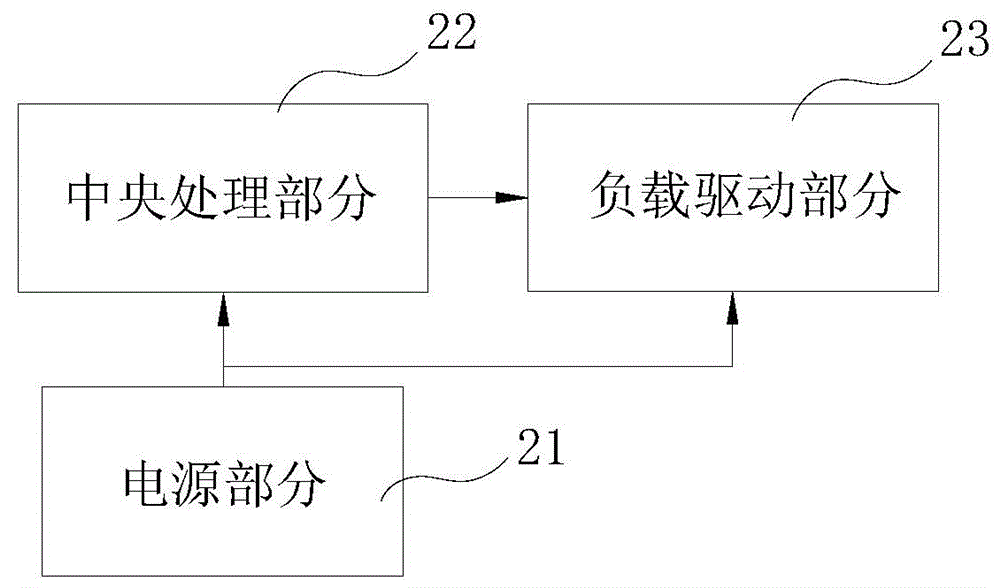

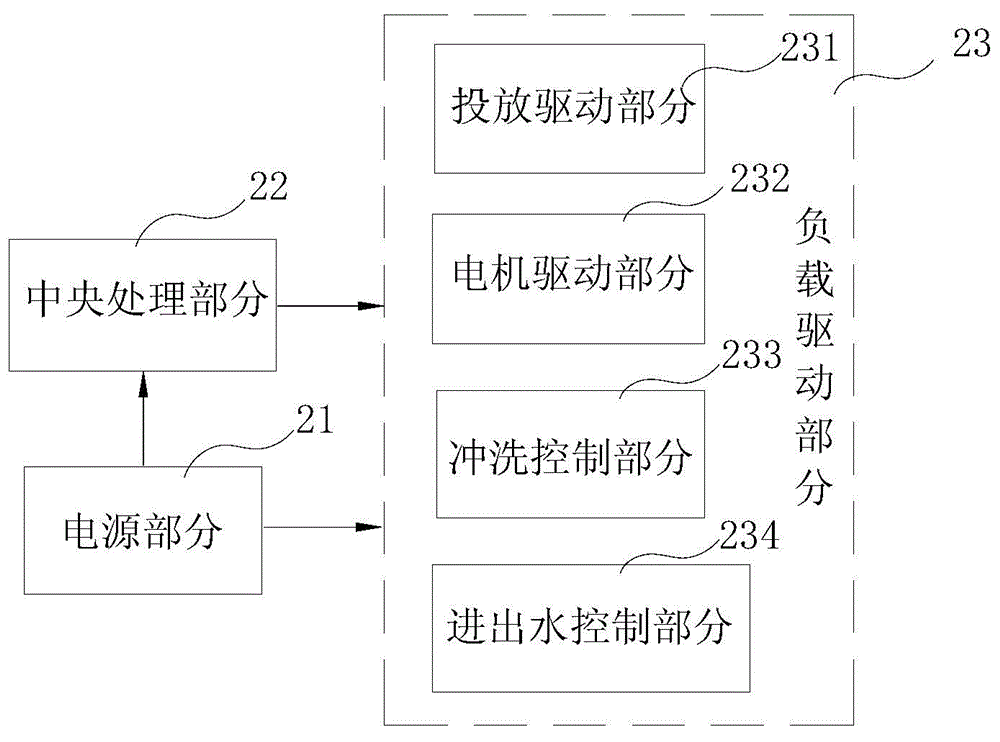

[0049] Such as Figure 4 As shown, in this embodiment, the main body 16 of the washing machine is connected to the circulating water treatment module 2, and the central processing part 22 of the circulating water treatment module 2 needs to be connected with the main control board 17 of the washing machine through the communication part 24, so as to be combined with the washing program. , smoothly complete the washing task and achieve the expected purpose of water saving. In addition, in order to achieve the expected flocculation effect, it is also necessary to detect the water quantity and water quality to be treated; at the same time, it is necessary to confirm the water quality after treatment, so the circulating water treatment module 2 also needs to increase the treated water detection part 25, so as to achieve closed-loop control.

Embodiment 2

[0051] Such as Figure 5 As shown, in this embodiment, the circulating water treatment module 2 and the main body 16 of the washing machine are designed in a unified manner. When the power of the washing machine power board 18 is sufficient, the power required for the circulating water treatment module 2 is directly provided by the washing machine power board 18, which can save costs and simplify structure.

Embodiment 3

[0053] Such as Figure 6 As shown, in this embodiment, the circulating water treatment module 2 and the main body 16 of the washing machine are designed independently, so the power supply part 21 needs to be reserved and the operation and display part 26 needs to be added. The power supply part of the circulating water treatment module supplies power to the operation and display part, the central processing part and the load driving part respectively.

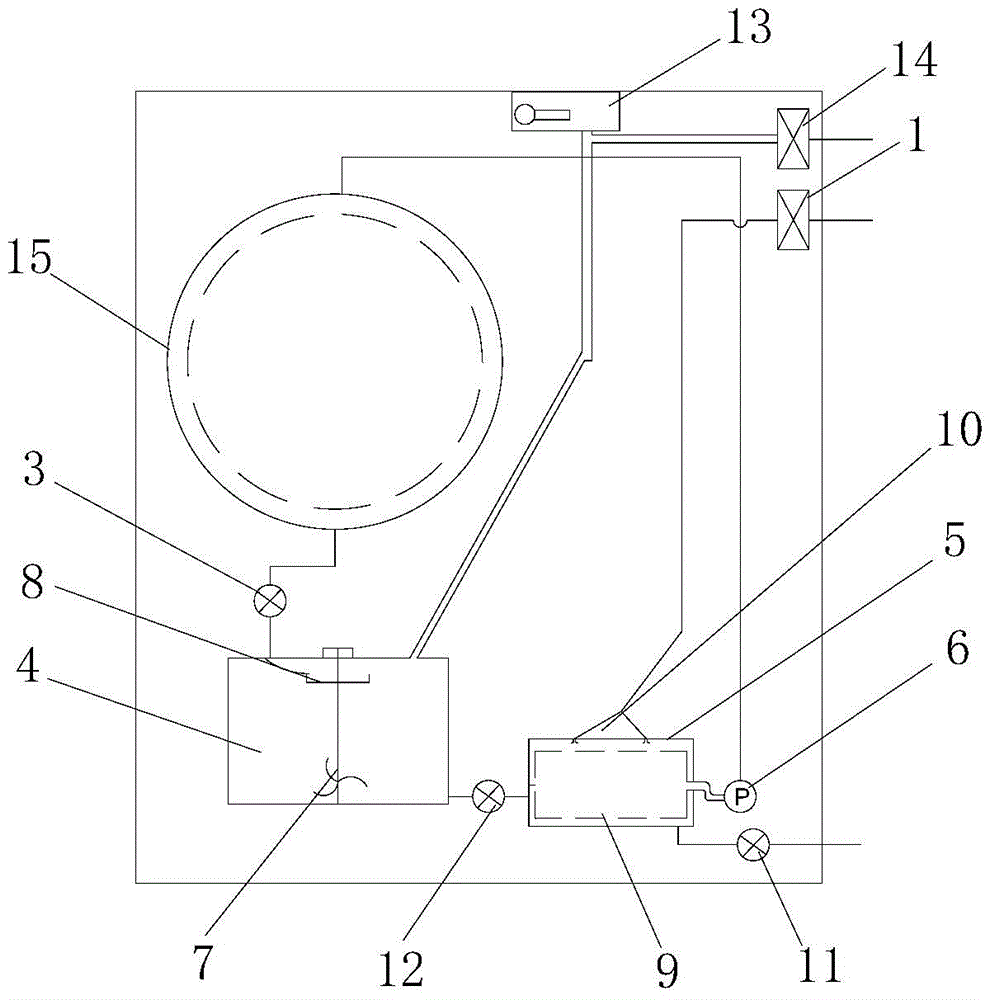

[0054] Such as figure 1 and Figure 7 As shown, the filter container 5 described in the washing machine of the present invention is provided with a filter water outlet 51 communicated with the water tub 15 and a sewage outlet 52 that cleans water is discharged (see Figure 8 ), the flocculation container 4 communicates with the filter container 5, and the cleaning water for cleaning the flocculation container 4 is discharged into the filter container 5 and discharged by the filter container sewage outlet 52. The flocculation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com