Threaded spring buffer rolling washing device of copper alloy disk-type motor

A threaded spring and disc motor technology, which is applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of longer sealing of the motor shaft, increase of the bottom size of the outer casing, and increase of the diameter of the motor shaft to achieve vibration Reduced width, compact overall size, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment:

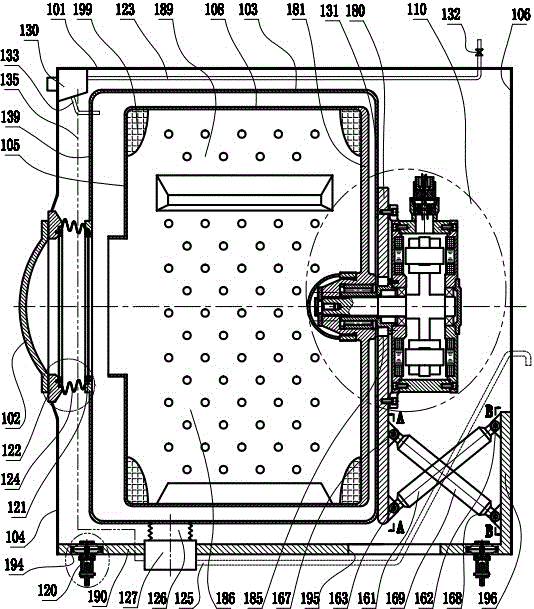

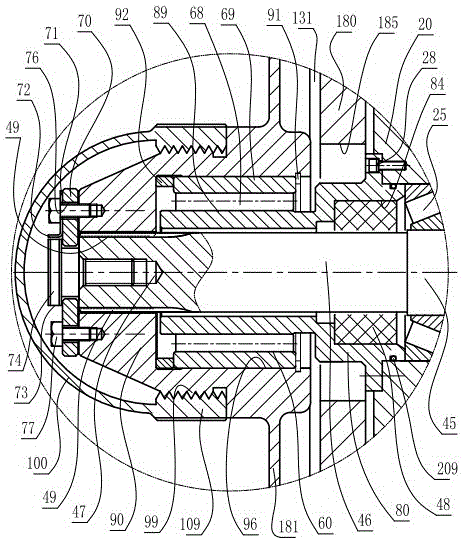

[0047] figure 1 with Figure 7 Middle: copper alloy disc motor threaded spring buffer washing machine, including: outer shell 101, drum door 102, water tank 103, tumbling drum 108, upright plate 180, base plate 190, disc flameproof motor assembly 110 and Outer water supply pipe 123 and drain outer pipe 125, outer casing 101 has control operation box 130 on the front upper part, the inner end of outer water supply pipe 123 is connected with control operation box 130, the outer end of outer water supply pipe 123 is connected with water inlet valve 132, the outer water supply The pipe 123 is connected to the internal anti-vibration water inlet pipe 133 after passing through the control operation box 130, and the outlet of the internal anti-seismic water inlet pipe 133 is located at the upper part of the inner cavity of the water tank 103; the control operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com