Method and device for identifying the soot and ash load of a particle filter

A particle filter, soot loading technology, applied in the direction of exhaust device, muffler device, electronic control of exhaust gas treatment device, etc., can solve the problem that absolute pressure difference cannot be realized, improve diagnosis quality, suppress signal fluctuation, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

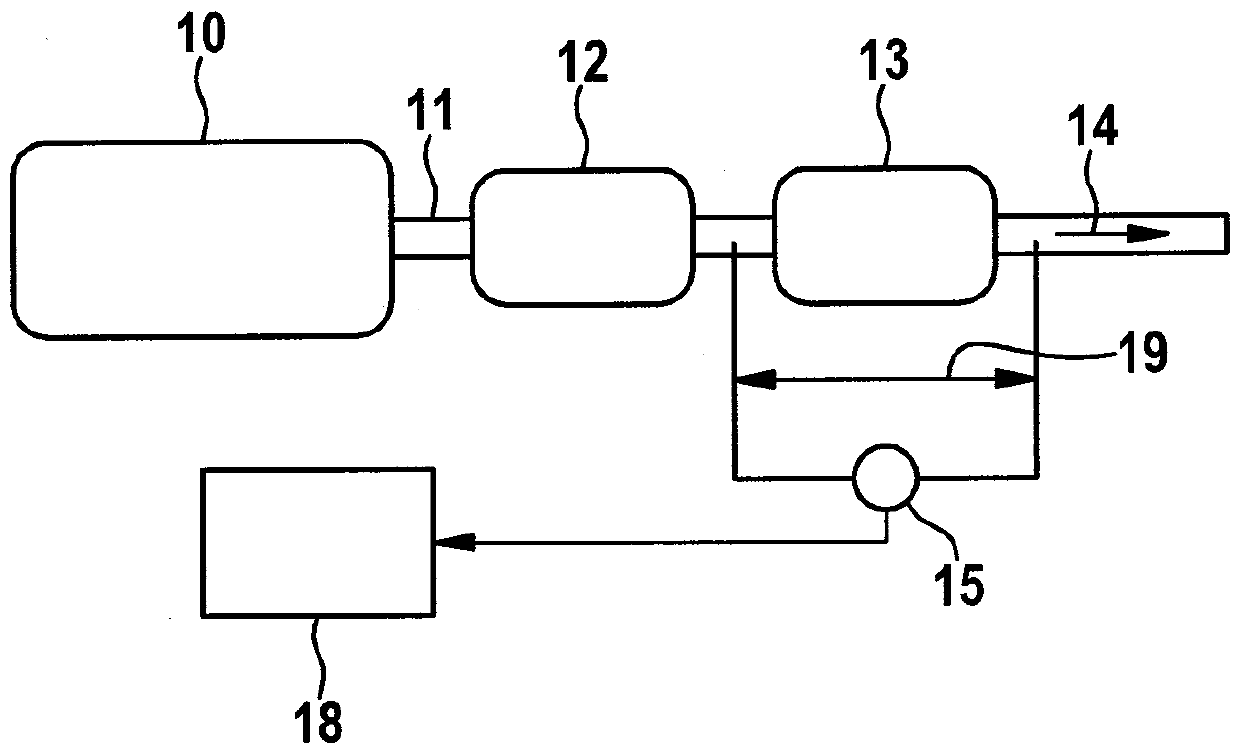

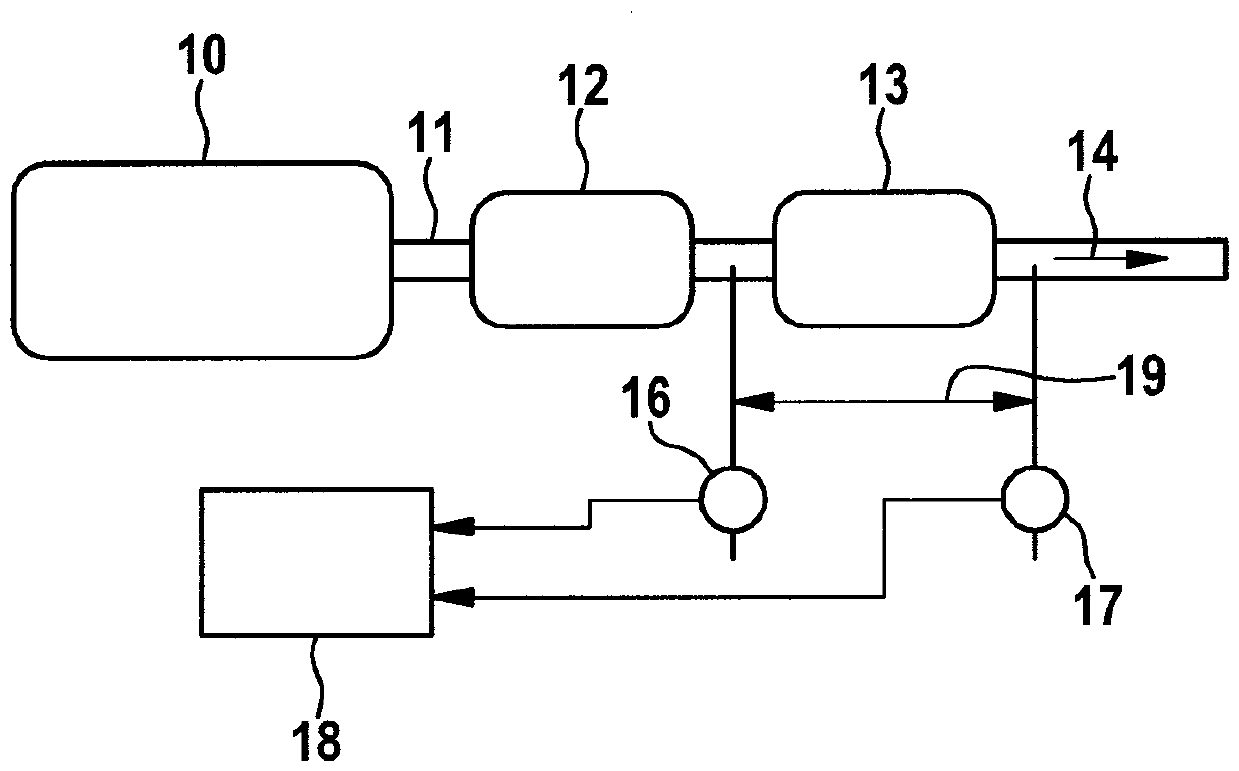

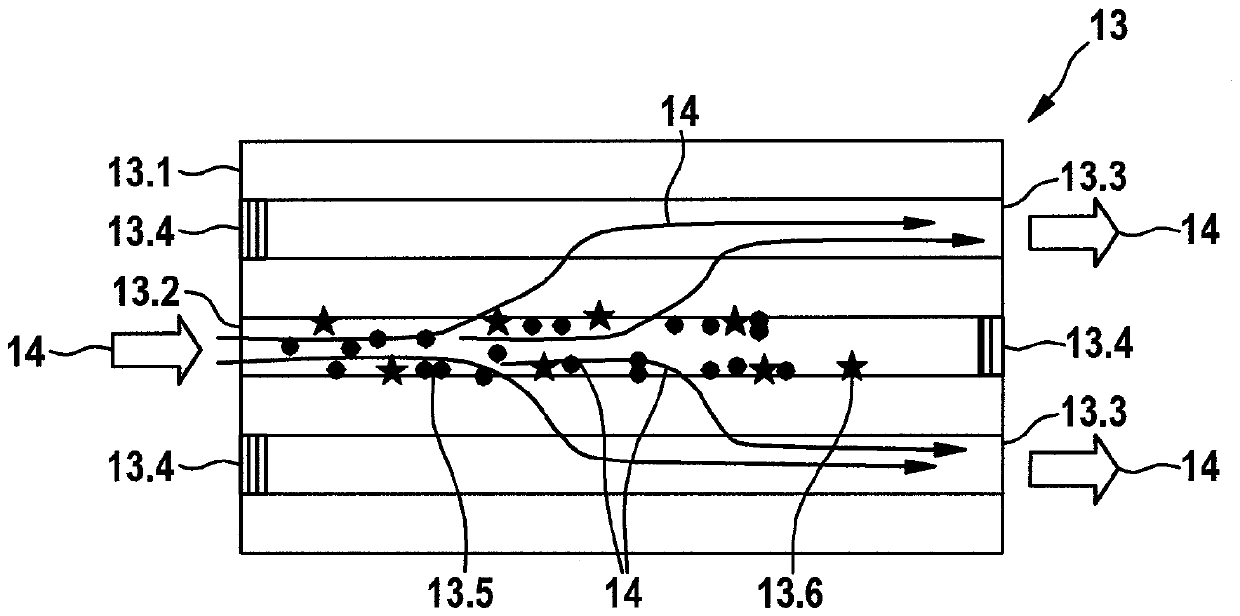

[0032] figure 1 The technical field in which the method according to the invention can be applied is schematically shown. An internal combustion engine 10 is shown as an example, which is embodied as a gasoline motor, wherein the exhaust gas of the internal combustion engine is conducted via an exhaust gas line 11 in which an exhaust gas cleaning device is arranged, which in the example shown is implemented in multiple stages . In the flow direction of the exhaust gas (exhaust gas flow 14 ), in the example shown there is firstly a catalytic converter 12 , which can be designed as a three-way catalytic converter, after which a particle filter 13 is arranged. Furthermore, exhaust gas sensors or other sensors, which of course are not shown in this schematic diagram, are usually arranged in the exhaust gas line 11 , the signals of which are fed to a motor control system (Electronic Control Unit ECU).

[0033] In order to diagnose the soot and ash load of the particle filter 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com