A sealless lng submersible pump

A sealless, submersible pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of long time, inability to refill the submersible pump, and inexhaustible unloading, etc. Anti-cavitation performance, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

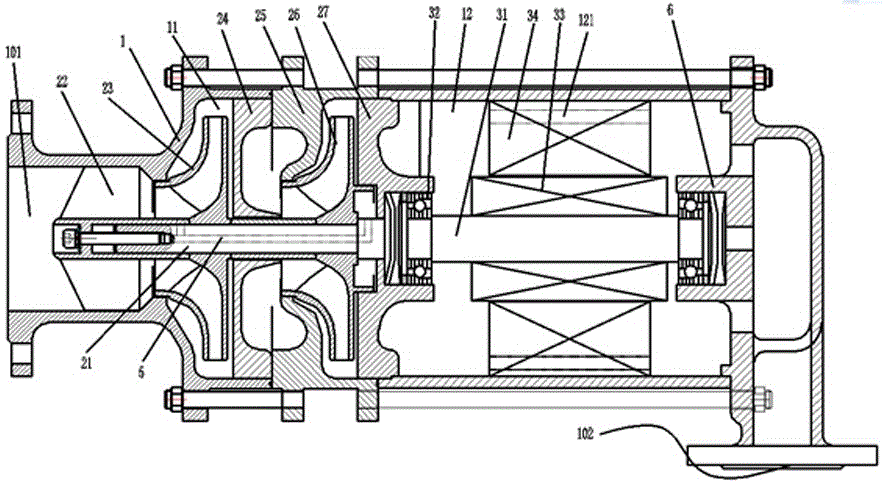

[0020] A kind of sealless LNG submersible pump, as attached figure 1 As shown, it includes a casing 1 forming a first cavity 11 and a second cavity 12, a pump main body set in the first cavity 11 through a pump main shaft, and a low temperature bearing 32 set in the second cavity 12. Drive motor; the second cavity 12 is located above the first cavity 11, the housing 1 has a liquid inlet 101 below the first cavity 11, and a liquid outlet 102 above the second cavity 12, LNG It is output from the liquid inlet 101 through the first cavity 11 and the second cavity 12 to the liquid outlet. The functional parts arranged along the pump main shaft 21, from the liquid inlet 101 to the liquid outlet 102, sequentially include the inducer 22, the first impeller 23, the first guide vane 24, the secondary housing 25, the secondary impeller 26, and the secondary guide vane 27 , the driving shaft 31 of the driving motor is arranged coaxially with the pump main shaft 21, and the secondary guid...

Embodiment 2

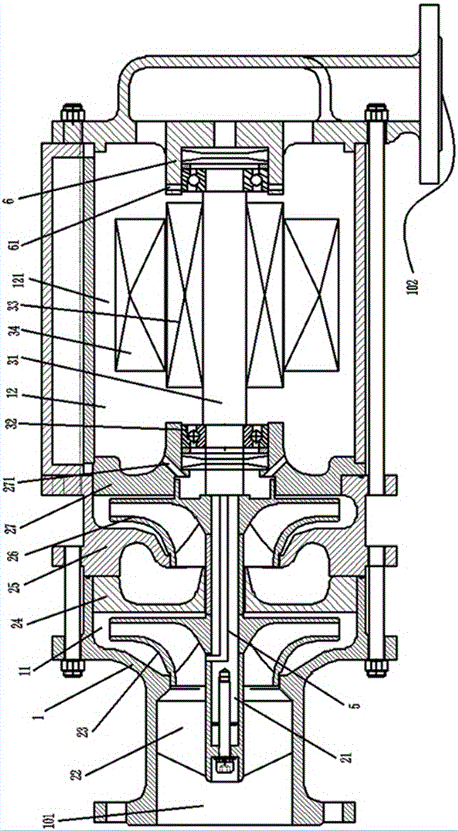

[0022] A kind of sealless LNG submersible pump, as attached figure 2 As shown, it includes a casing 1 forming a first cavity 11 and a second cavity 12, a pump main body set in the first cavity 11 through a pump main shaft, and a low temperature bearing 32 set in the second cavity 12. Drive motor; the second cavity 12 is located above the first cavity 11, the housing 1 has a liquid inlet 101 below the first cavity 11, and a liquid outlet 102 above the second cavity 12, LNG It is output from the liquid inlet 101 through the first cavity 11 and the second cavity 12 to the liquid outlet. The functional parts arranged along the pump main shaft 21, from the liquid inlet 101 to the liquid outlet 102, sequentially include the inducer 22, the first impeller 23, the first guide vane 24, the secondary housing 25, the secondary impeller 26, and the secondary guide vane 27 , the driving shaft 31 of the driving motor is arranged coaxially with the pump main shaft 21, and the secondary gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com