Device and method for automatically measuring multiple motor characteristics

An automatic measurement and characteristic technology, applied in the direction of motor generator testing, etc., can solve problems such as time-consuming, high manufacturing cost, and unsatisfactory adjustment effect accuracy, to achieve voltage accuracy guarantee, reduce measurement and operation time, and manufacturing cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

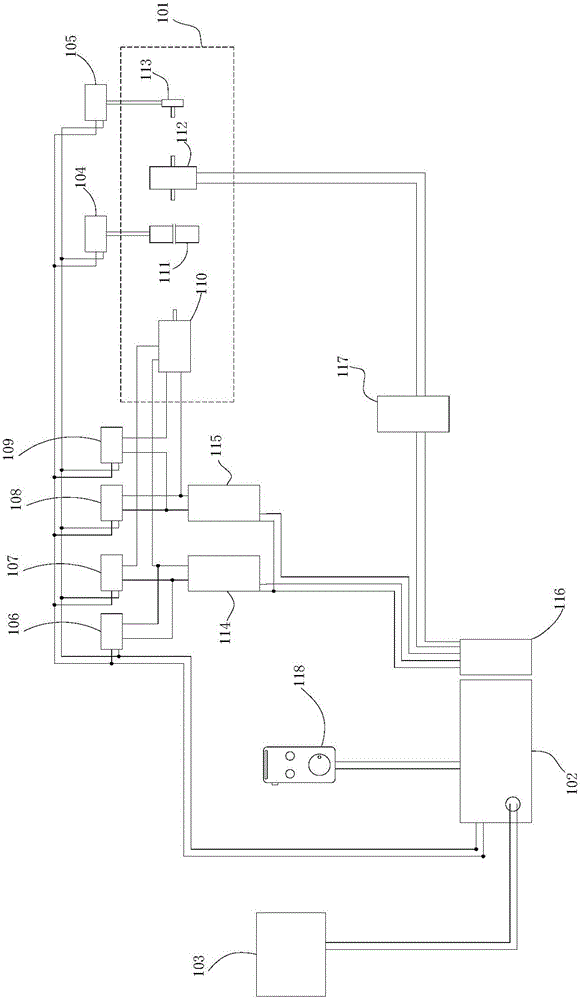

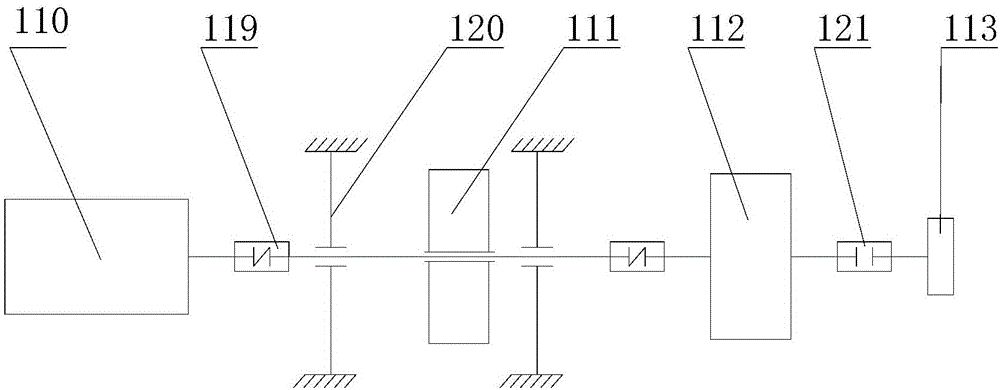

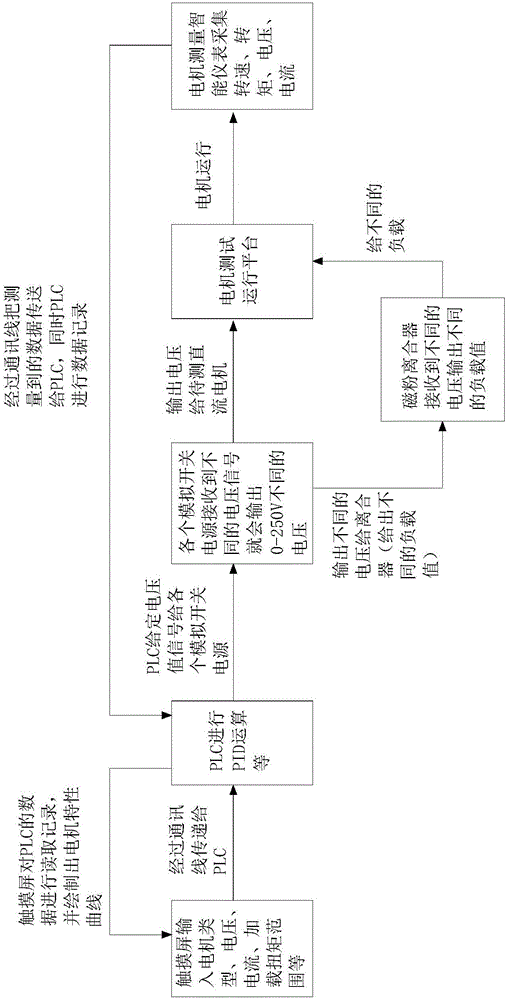

[0047] Such as figure 1 As shown, a variety of motor characteristic automatic measurement devices include a DC motor operating platform 101 to be tested and a PLC 102, wherein the DC motor operating platform 101 to be tested includes a DC motor to be tested 110, a rotary encoder 111, a magnetic powder clutch 112, a static torque The sensor 113 is connected coaxially among the four in turn; in addition, it also includes a touch screen 103 connected to the PLC 102 in communication, and the touch screen 103 is provided with a motor parameter setting module, a measurement data recording module and a PLC switch control module. By setting the motor parameter setting module and the PLC switch control module, the user can set the motor parameters and control the startup and shutdown of the PLC102 on the touch screen 103. The motor parameter setting module and the PLC switch control module are specifically displayed on the touch screen in the form of a setting interface. display; and b...

Embodiment 2

[0063] Such as Figure 4 As shown, a variety of motor characteristic automatic measurement devices include an AC motor operating platform 201 to be tested and a PLC 202, wherein the AC motor operating platform 201 includes a DC motor to be tested 207, a rotary encoder 208, a magnetic powder clutch 209, a static torque The sensor 210 is connected coaxially among the four in sequence. In addition, it also includes a touch screen 203 communicating with the PLC 202. The touch screen 203 is provided with a motor parameter setting module, a measurement data recording module and a PLC switch control module. By setting the motor parameter setting module and the PLC switch control module, the user can set the motor parameters and control the startup and shutdown of the PLC202 on the touch screen 203. The motor parameter setting module and the PLC switch control module are specifically displayed on the touch screen in the form of a setting interface. display; and by setting the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com