Two-way flexible loading system and method for simulating three-dimensional coal seam mining test bench

A loading system and flexible loading technology, which is applied in the field of simulation systems, can solve problems such as inability to completely discharge air, short life, and inaccurate test results, so as to improve authenticity and credibility, light and easy to operate, and improve test reality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with specific embodiments.

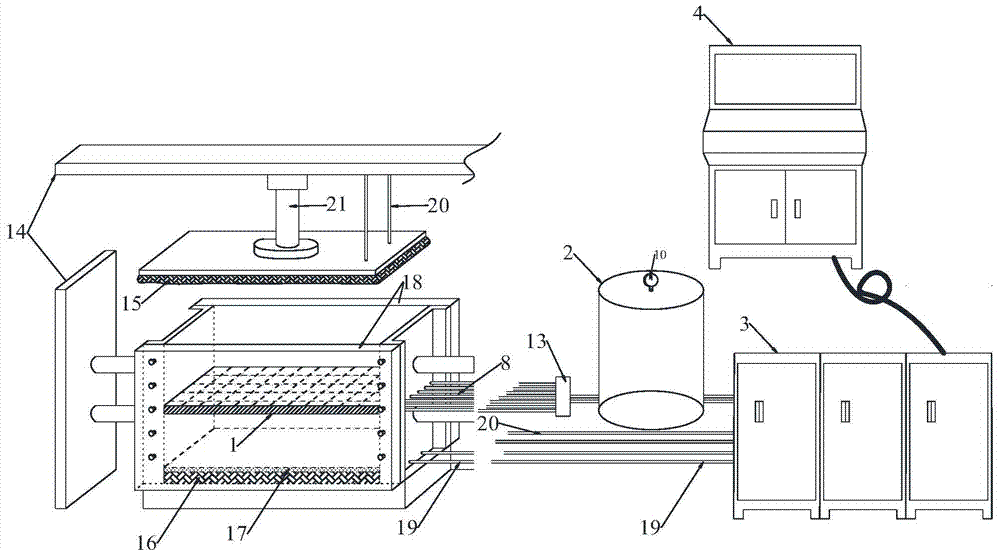

[0049] The present invention is a loading system for simulating a three-dimensional coal seam mining test bench, such as figure 1 As shown, it includes a frame test bench 14 carrying a model, a three-dimensional mining simulation system, a pneumatic loading system 3 and a numerical control system 4, wherein the pneumatic loading system 3 and the numerical control system 4 are used to provide and deliver gas to the three-dimensional mining simulation system, It can adopt the loading system and numerical control system of the conventional structure in the prior art.

[0050] The innovative part of the present invention will be described in detail below.

[0051] Frame type test bench 14, comprises upper opening, is positioned at front, rear, left and right side wall panels, and base plate; Front and rear side wall panels are plexiglass plates, can conveniently observe the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com