Variable-frequency cable

A frequency conversion cable and cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of inability to maintain the stability of the cable structure, affect the reliability and life of the motor, and poor corrosion resistance, so as to ensure the self-lubricating characteristics , Outstanding shock absorption and buffering effect, and the effect of improving shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below through specific embodiments. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

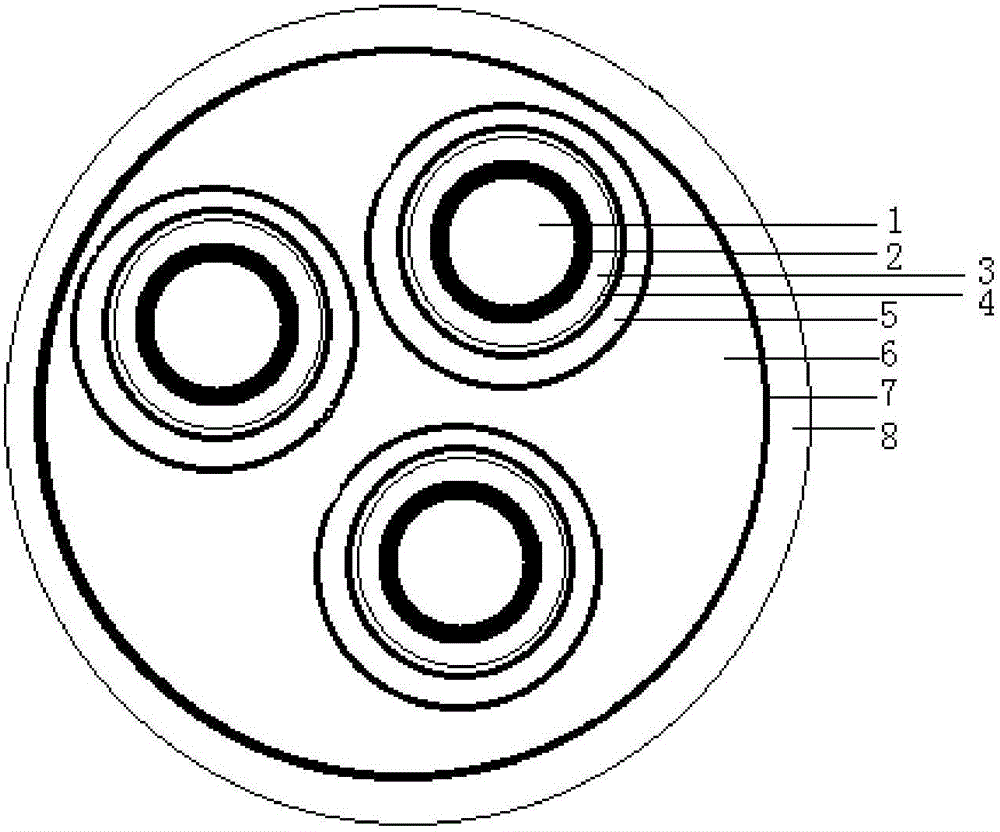

[0024] The present invention provides a figure 1 The frequency conversion cable shown includes an outer sheath layer 8 and an insulating layer 5. The outer sheath layer 8 includes fluororubber, polyisocyanate and polyurethane elastomer; the insulating layer 5 includes an inner insulating layer and an outer insulating layer. The insulating layer includes fluoroplastics and polyvinyl chloride, and the outer insulating layer includes polyhexamethylene adipate.

[0025] The cable also includes an inner core and an inner liner 3, the inner liner 3 is close to the outside of the inner core of the cable, and the inner liner 3 includes polyvinyl chloride and polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com