A kind of semiconductor device and its preparation method, electronic device

A semiconductor and device technology, applied in the field of semiconductor devices and their preparation, can solve the problems of rough slope profile, unfavorable process, difficult and other problems, and achieve the effect of improving performance and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

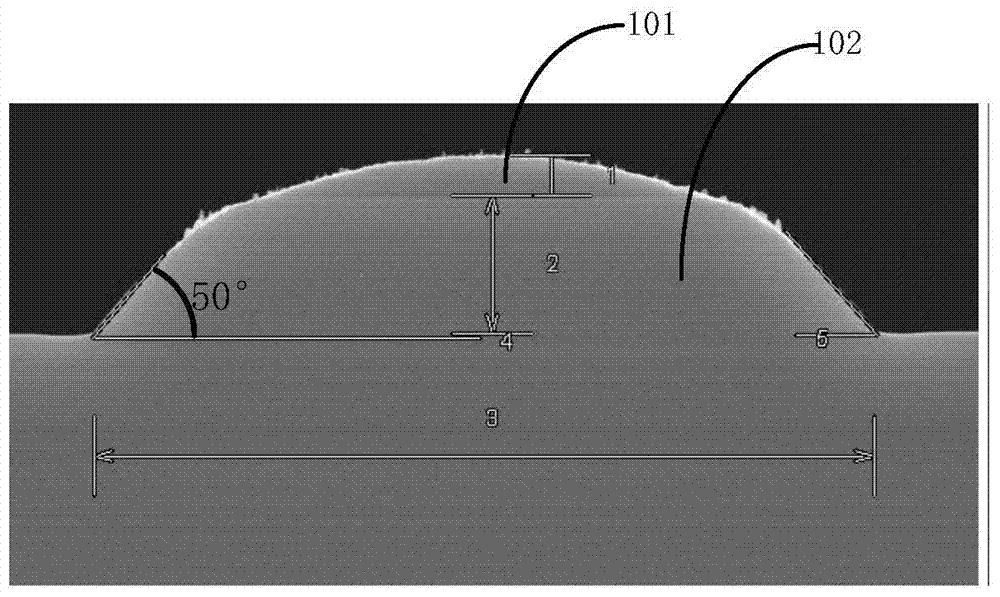

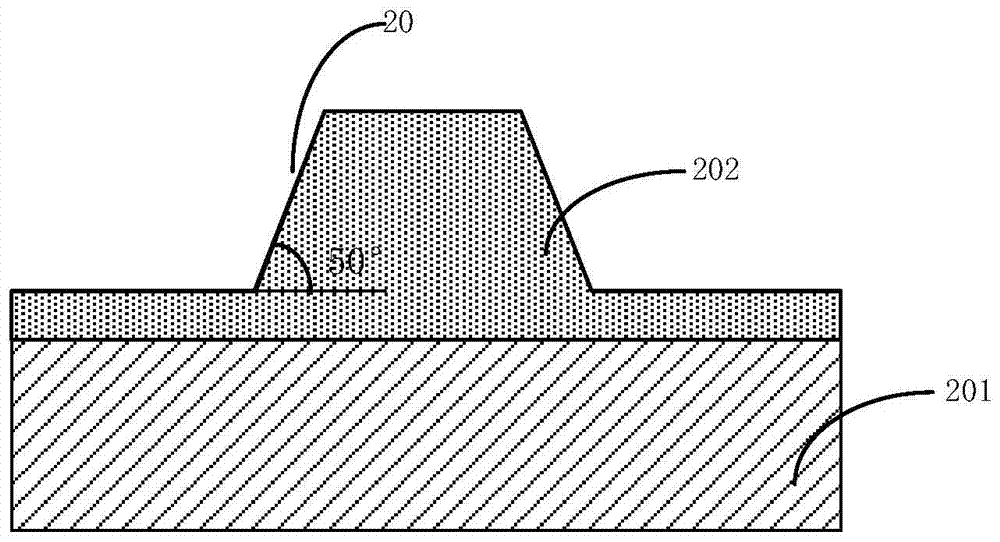

[0051]There are currently two methods for preparing slopes in semiconductor devices: the first one is to provide a base 102, and then form a patterned photoresist 101 on the base, the photoresist layer has a tapered profile, and then the The pattern is transferred to the substrate 102. The second method is to provide the substrate, then use dry etching, and adjust the parameters in the dry etching process to obtain the target slope, but the above two methods have disadvantages, such as the target slope The acute angle formed with the horizontal plane is 30-40°, but the acute angle formed between the slope prepared by the above two methods and the horizontal plane is about 50°, such as figure 1 As shown, it is difficult to achieve the target angle, the process is difficult to control, and the prepared inclined surface is rough, which is not conducive to the subsequent process.

[0052] In order to obtain a slope with a gentler slope, the present invention eliminates the limitat...

Embodiment 1

[0056] Attached below Figure 2a-2e The method is described further.

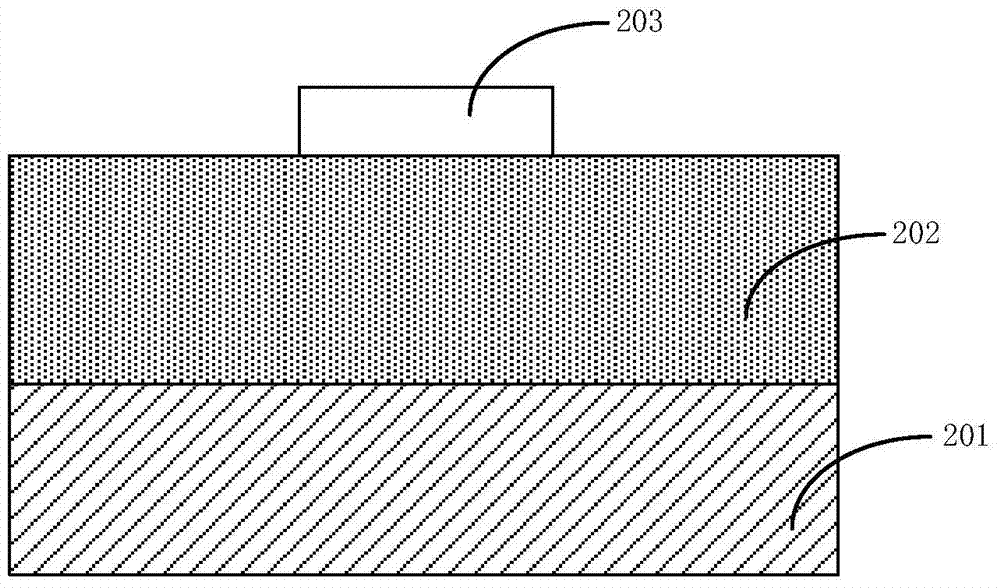

[0057] First, step 201 is performed to provide a semiconductor substrate 201 on which an oxide layer 202 is formed.

[0058] Specifically, such as Figure 2a As shown, the semiconductor substrate 201 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI ), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0059] In this embodiment, the semiconductor substrate 201 is made of silicon.

[0060] The oxide layer 202 is silicon oxide, but not limited to silicon oxide, the oxide mask layer can also be ZnO, CdO, TiO 2 、Al 2 o 3 , SnO, Cu 2 O, NiO, CoO, FeO, and Cr 2 o 3 One of.

[0061] Step 202 is executed to form a patterned mask layer 203 on the oxide layer 202 , and a stripe pattern is formed in the mask layer 203 .

[0062] Specifically, the mask layer 203 can be...

Embodiment 2

[0101] Attached below Figure 3a-3f The method is described further.

[0102] First, step 301 is performed to provide a semiconductor substrate 301 on which an oxide layer 302 is formed.

[0103] Specifically, such as Figure 3a As shown, the semiconductor substrate 301 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI ), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0104] In this embodiment, the semiconductor substrate 301 is silicon.

[0105] The oxide layer 302 is silicon oxide, but not limited to silicon oxide, the oxide mask layer can also be ZnO, CdO, TiO 2 、Al 2 o 3 , SnO, Cu 2 O, NiO, CoO, FeO, and Cr 2 o 3 One of.

[0106] Step 302 is executed to form a patterned mask layer 303 on the oxide layer 302 , and a stripe pattern is formed in the mask layer 303 .

[0107] Specifically, the mask layer 303 can be a mask ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com