Surface mounting machine clamping device

A technology of clamping device and placement machine, which is applied in the direction of assembling printed circuit of electrical components, electrical components, PCB positioning during processing, etc. It can solve the problems of easily damaged PCB board, slow response speed, and low processing accuracy. Achieve the effects of high degree of automation, fast response and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

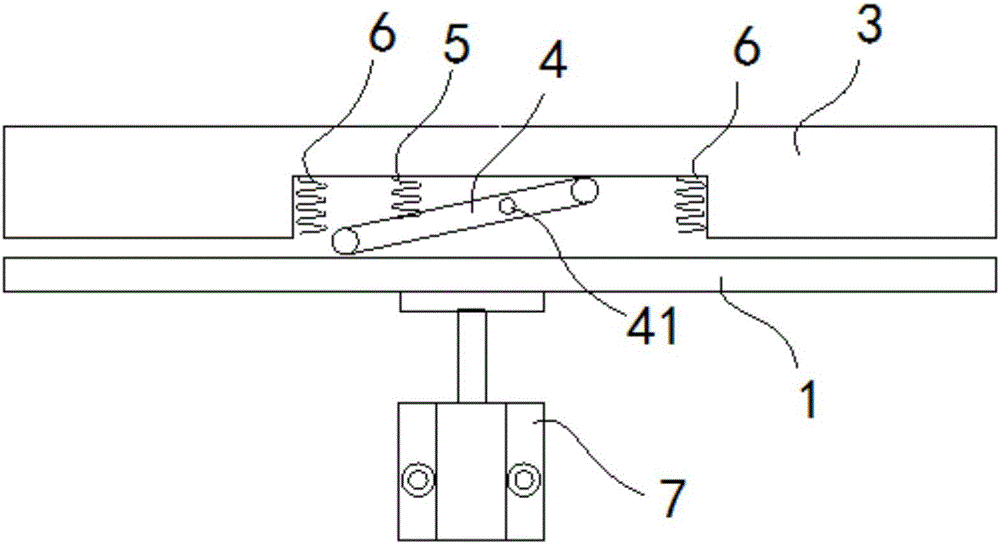

[0025] like figure 1 As shown, the clamping device of the chip mounter of the present invention includes: a first clamping plate 1 , a second clamping plate 3 , a lever 4 , a compression spring 5 , a tension spring 6 , and an air cylinder 7 .

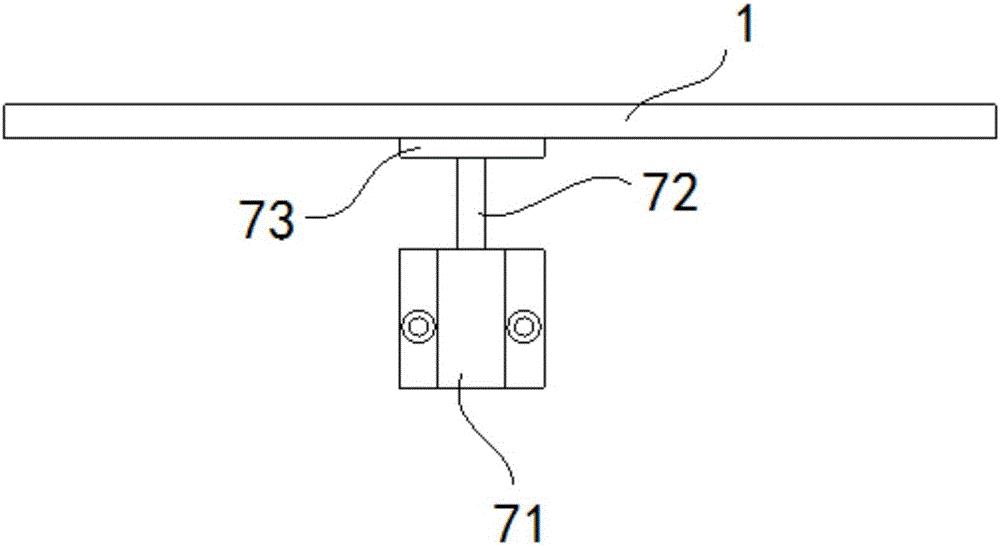

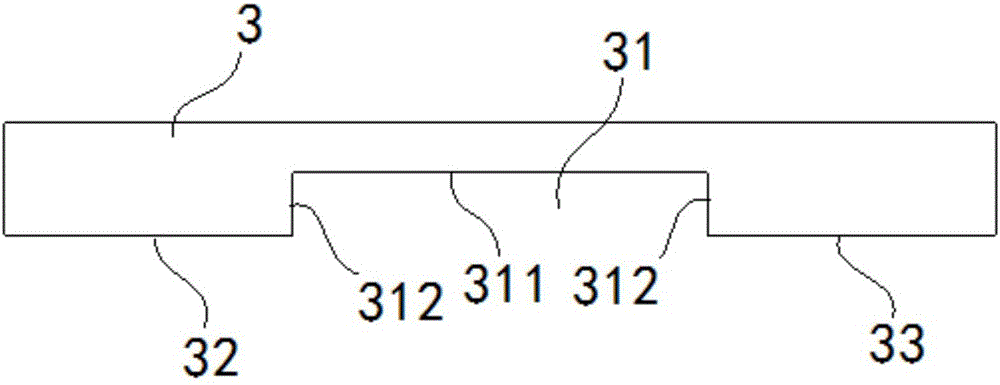

[0026] The first clamping plate 1 is arranged below the transmission belt 2 (not shown in the figure). The width of the first clamping plate 1 is greater than the width of the second clamping plate 3 . The first splint 1 is a straight plate, and a plurality of array holes can be set on the first splint 1 for inserting support nails. On the one hand, the quality of the first splint itself is reduced. When inserting the support pins, it can withstand the PCB board, avoid the depression in the middle of the PCB board, and reduce the patch error. like figure 2 As shown, a cylinder 7 is arranged below the first clamping plate 1 , and the cylinder 7 is connected to the lower surface of the first clamping plate 1 . The cylinder 7 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com