Seal device

A sealing device and combined sealing technology, which is applied in the direction of engine seals, piston rings, mechanical equipment, etc., can solve the problem of large assembly resistance when inserting external components, and achieve the effect of avoiding oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

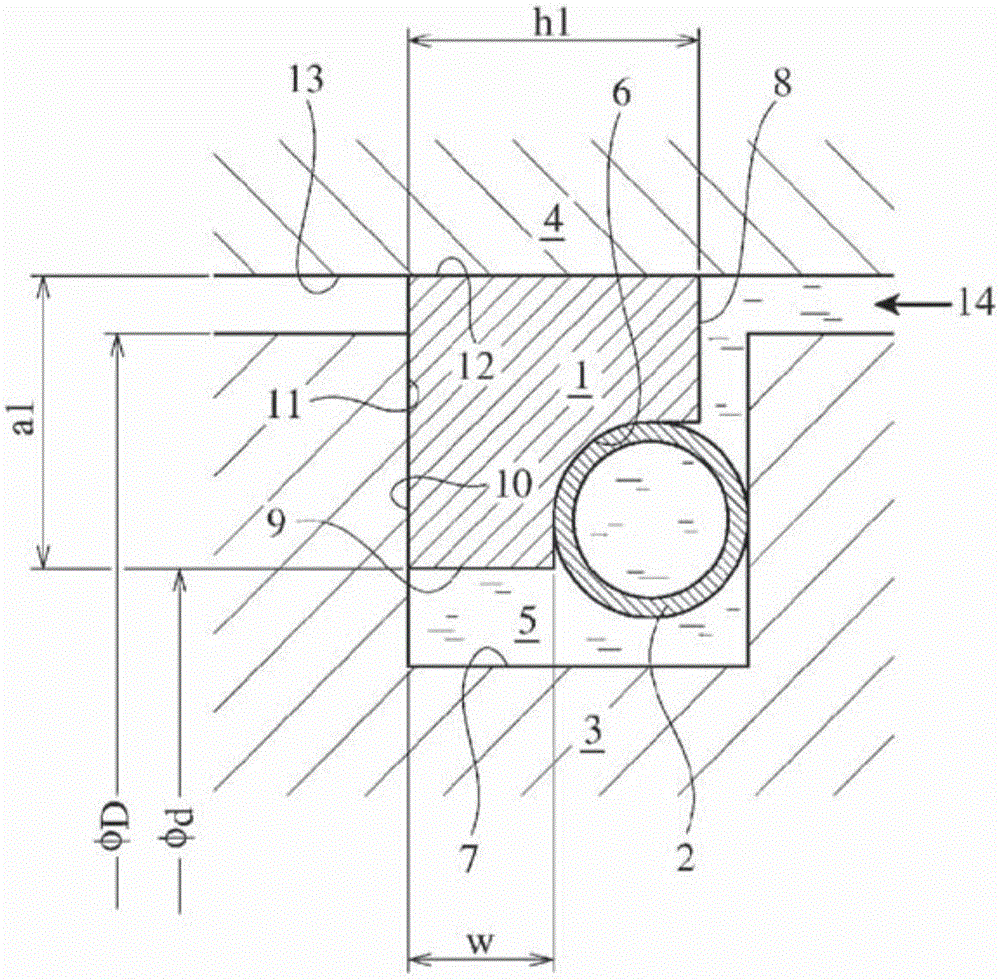

[0036] Using PTFE resin made of composite carbon, a ring-type resin ring without a joint is produced. Here, the outer diameter (nominal diameter) of the resin ring was 114.5 mm, the thickness (radial width a1) was 3.2 mm, and the width (axial width h1) was 2.7 mm. In the obtained resin rings, there are formed in figure 1 In the cross section shown, the opening width (w) on the inner peripheral surface side is 1.0 mm, and the cutout portion has a radius of curvature of 0.8 mm. In addition, using a SWOSC-V material with a wire diameter of 0.6mm, a spiral expander with a coil diameter of φ1.5mm, a gap of 1.65mm in a free state, and a tension of 10N when combined with a resin ring was produced.

[0037] leak test

[0038] use Figure 6 A leak test machine whose outline is shown in The manufactured combined seal ring is fitted into the seal ring groove 5 provided in the inner member 3 and inserted into the outer member 4 . The diameter of the inner member 3 of the leak tester...

Embodiment 2

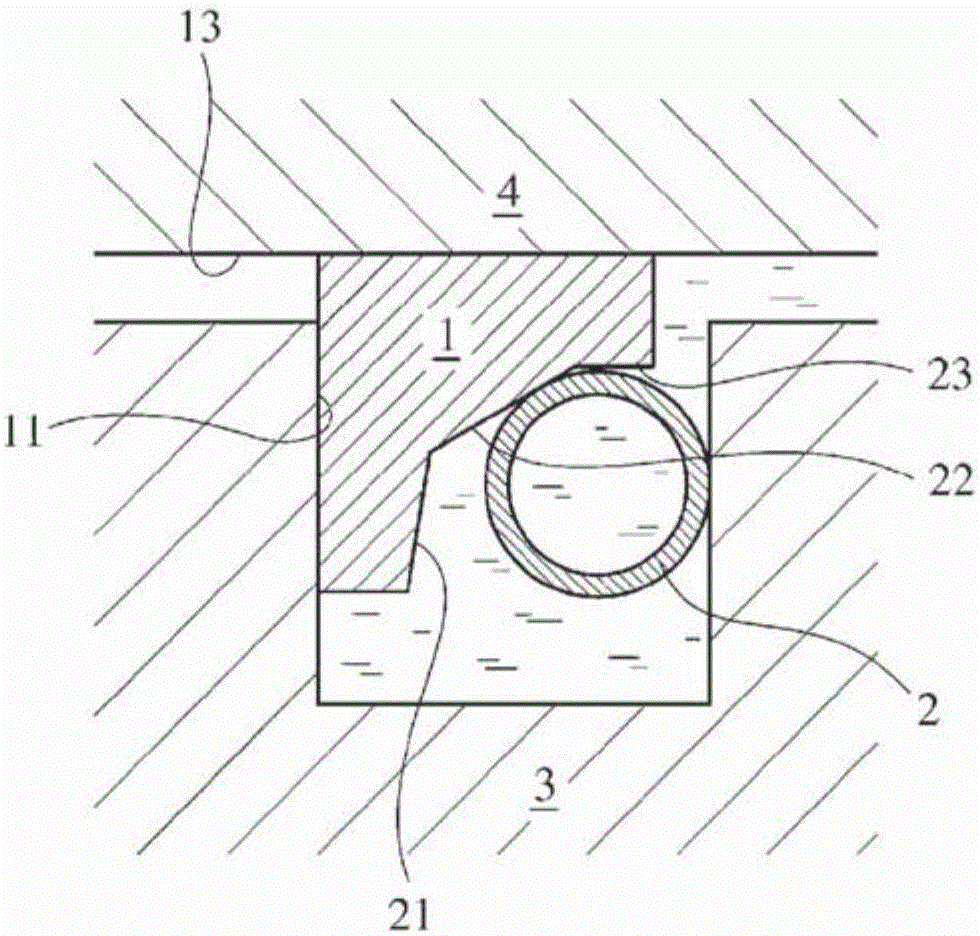

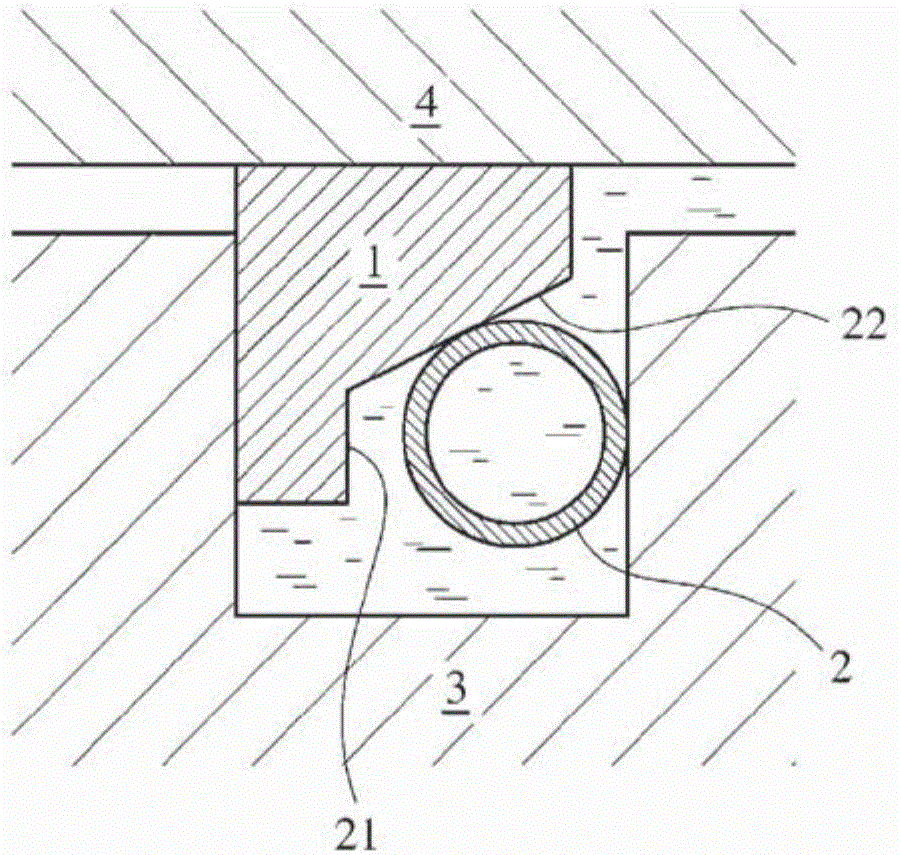

[0040] In addition to making figure 2 A combined seal ring was produced in the same manner as in Example 1 except for the shown resin ring 1 having a cut portion composed of three surfaces 21 , 22 , and 23 . Here, the opening width (w) of the inner peripheral surface side of the cutting portion is 2.0 mm (74% of h1), the surface 23 is 0.9 mm parallel to the axial direction of the resin ring 1, and the inclination angle of the surface 22 is 30°. The angle of inclination of the face 21 is 80°. As a result of the same leak test as in Example 1, no leak occurred before and after the heat history.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com