Forced heat recovery type energy-saving tobacco curing barn

A heat recovery type, flue-cured tobacco room technology, applied in the preparation of tobacco, tobacco, final product manufacturing, etc., can solve problems such as waste, non-energy saving, and serious problems, and achieve the effects of avoiding heat loss, saving electric energy, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention is further introduced below in conjunction with the accompanying drawings and specific embodiments:

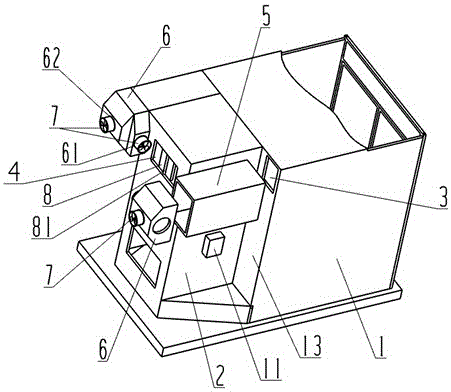

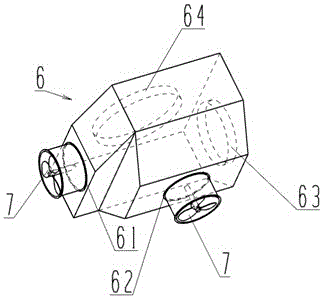

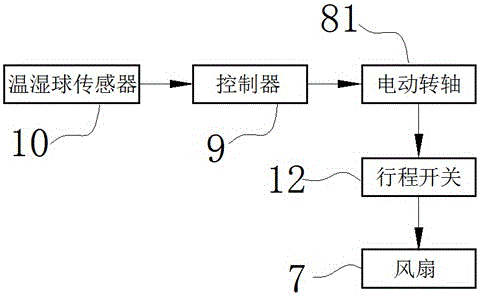

[0025] like figure 1 As shown in the figure, a forced heat recovery type energy-saving flue-curing room includes a smoke-loading room 1, a heating room 2 and a total heat exchanger 6. The smoke-loading room 1 and the heating room 2 are separated by an insulating wall 13, so The two top corners of the heat insulating wall 13 are respectively provided with a moisture exhaust port 3 that communicates with the smoke chamber 1. The heating chamber 2 is provided with an air inlet 4, and the air inlet 4 passes through an electric rotating shaft 81. A damper 8 is provided in connection, and a total heat exchanger 6 is connected to the two moisture exhaust ports 3 through insulation pipes 5 respectively. The fresh air outlet 61 of the total heat exchanger faces the air inlet 8. A fan 7 is provided on both the fresh air outlet 61 and the moisture exhaust gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com