A kind of preparation method of cigar cigarette wrapper tobacco leaf

A technology for cigars and wrappers, which is applied in the field of tobacco production, can solve the problems of difficulty in meeting the needs of rapid development of cigars, restricting the rapid development of cigars, and low yield of wrappers, so as to achieve no bad smell, improve formulation efficiency and The effect of leveling and widening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

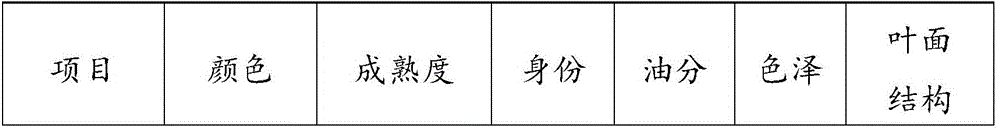

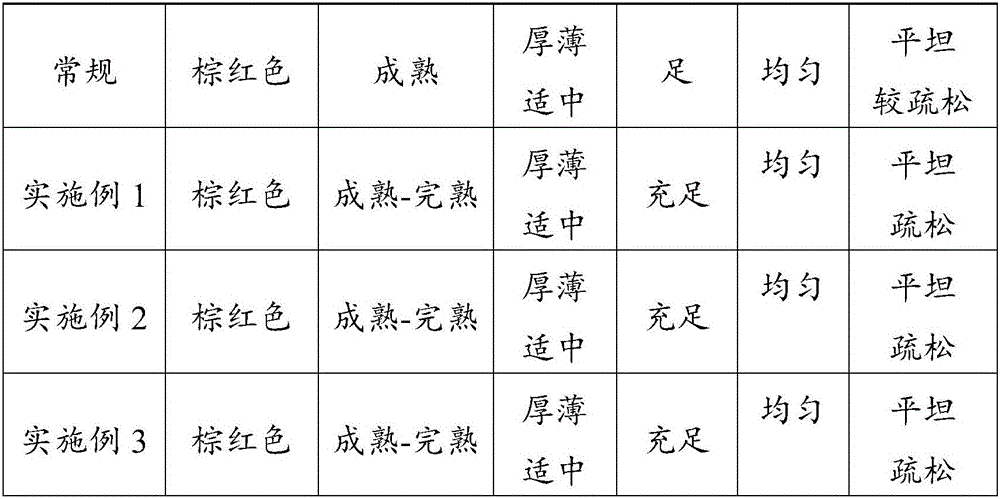

Examples

Embodiment 1

[0016] The first step, preparation of cigar tobacco raw material extraction solution: select 100kg of cigar tobacco low-grade tobacco leaves, powder, tobacco stems, etc., as raw materials, soak in 80kg of 70% ethanol for 5 hours, then heat and boil for 30 minutes, filter Concentrate the alcoholic solution under reduced pressure to obtain the cigar tobacco raw material extract, the concentration factor is 15 times, and collect the alcoholic solution, which can be reused.

[0017] The second step is to air-cure the mature flue-cured tobacco leaves after harvesting: after the middle part of the flue-cured tobacco leaves mature, the lower 3-5 pieces and the middle 6-8 pieces are harvested and stringed at one time, and air-cured according to the cigar preparation standard. The specific steps of air-curing are as follows: according to the color change of tobacco leaves, the air-curing process is divided into four stages: wilting, yellowing, browning, and tendon drying: (1) Withering ...

Embodiment 2

[0020] The first step, the preparation of cigar tobacco raw material extraction solution: select 100kg of cigar tobacco low-grade tobacco leaves, powder, tobacco stems, etc., as raw materials, soak in 100kg of 70% ethanol for 4 hours, then heat and boil for 30 minutes, filter Concentrate the alcoholic solution under reduced pressure to obtain the cigar raw material extract, the concentration factor is 20 times, and collect the alcoholic solution, which can be reused.

[0021] The second step is to air-cure the mature flue-cured tobacco leaves after harvesting: after the middle part of the flue-cured tobacco leaves mature, the lower 3-5 pieces and the middle 6-8 pieces are harvested and stringed at one time, and air-cured according to the cigar preparation standard. The air-curing steps are as follows: according to the color change of the tobacco leaves, the air-curing process is divided into four stages: withering, yellowing, browning, and tendon drying: (1) Withering stage: sm...

Embodiment 3

[0024] The first step, preparation of cigar tobacco raw material extraction solution: select 100kg of cigar tobacco low-grade tobacco leaves, crushed powder, tobacco stems, etc. as raw materials, soak in 120kg of 70% ethanol for 6 hours, then heat and boil for 40 minutes, filter Concentrate the alcoholic solution under reduced pressure to obtain the cigar raw material extract, the concentration factor is 10 times, and collect the alcoholic solution, which can be reused.

[0025] The second step is to air-cure the mature flue-cured tobacco leaves after harvesting: after the middle part of the flue-cured tobacco leaves mature, the lower 3-5 pieces and the middle 6-8 pieces are harvested and stringed at one time, and air-cured according to the cigar preparation standard. The air-curing steps are as follows: according to the color change of the tobacco leaves, the air-curing process is divided into four stages: withering, yellowing, browning, and tendon drying: (1) Withering stage:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com