Flue gas desulphurization system suitable for downstream spraying semi-dry method

A desulfurization system, semi-dry technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy blockage of water adding devices, difficult operation, and high energy consumption, and can improve the contact surface area and increase the reaction. Speed, the effect of prolonging the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific embodiments, so as to help understand the content of the present invention.

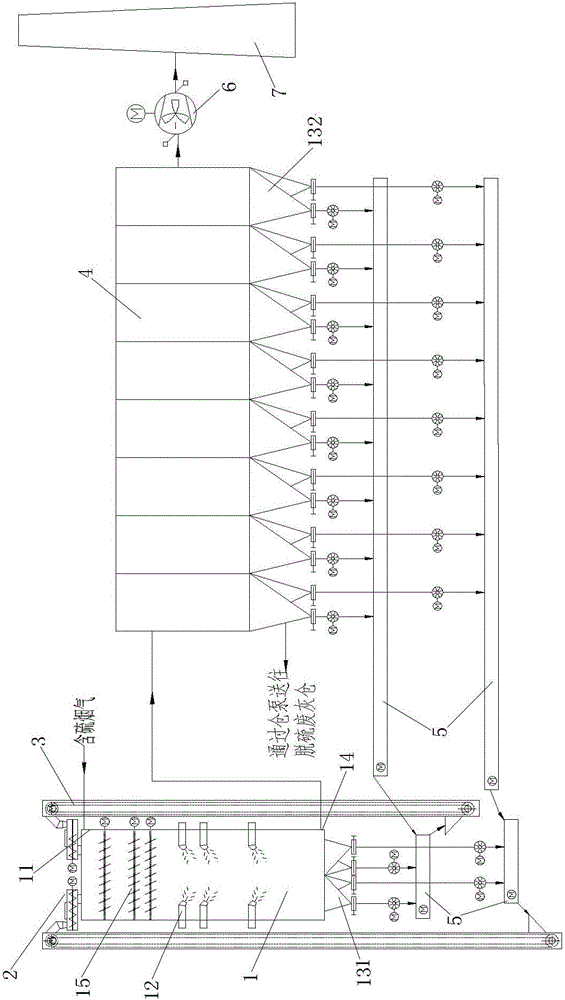

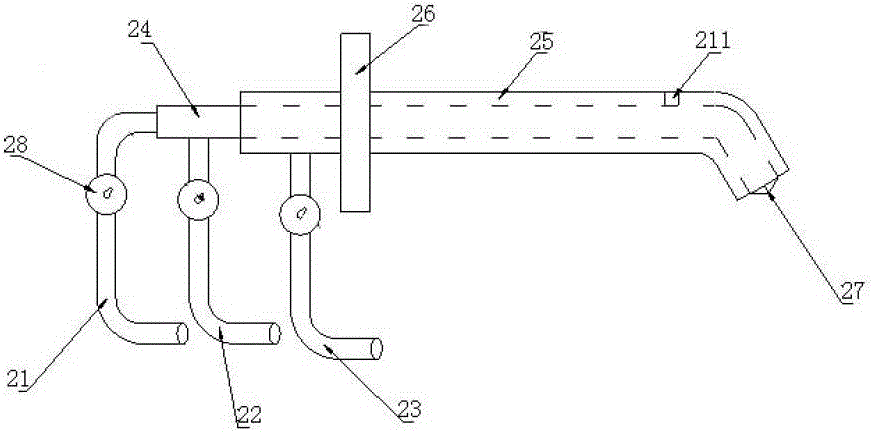

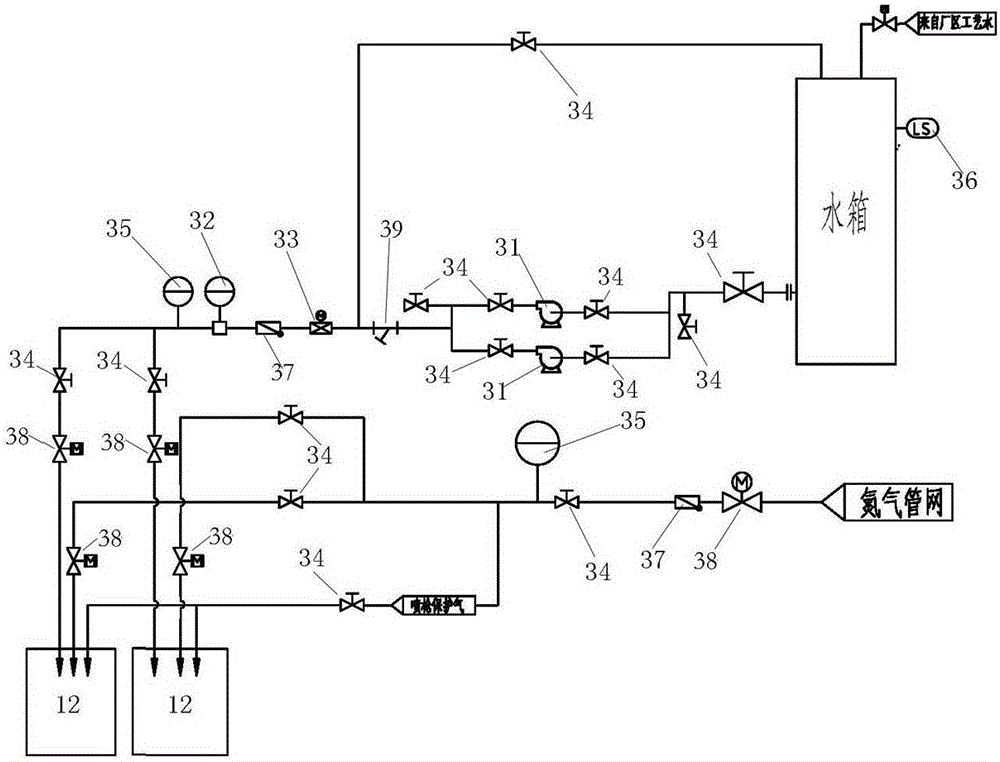

[0042] Such as figure 1 As shown, the flue gas desulfurization system applicable to the downstream spray semi-dry method of the present invention includes a desulfurization tower 1, a distribution machine 2, a material lifting and conveying device 3 and a bag filter 4, the desulfurization tower 1 is vertical, and the distribution machine 2 Located on the top of the desulfurization tower 1, the tower wall below the distribution machine 2 is provided with a flue gas inlet 11, and the space below the distribution machine 2 is also equipped with a material agitator 15, and a three-stage mist is installed from top to bottom along the axial direction of the middle of the desulfurization tower 1. There are at least two atomizing spray guns 12 arranged symmetrically in each stage, and the atomizing spray guns 12 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com