Full-automatic closing machine for needle valve

A fully automatic, closing machine technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low installation efficiency, achieve the effects of improving production efficiency, realizing automatic machine operation, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

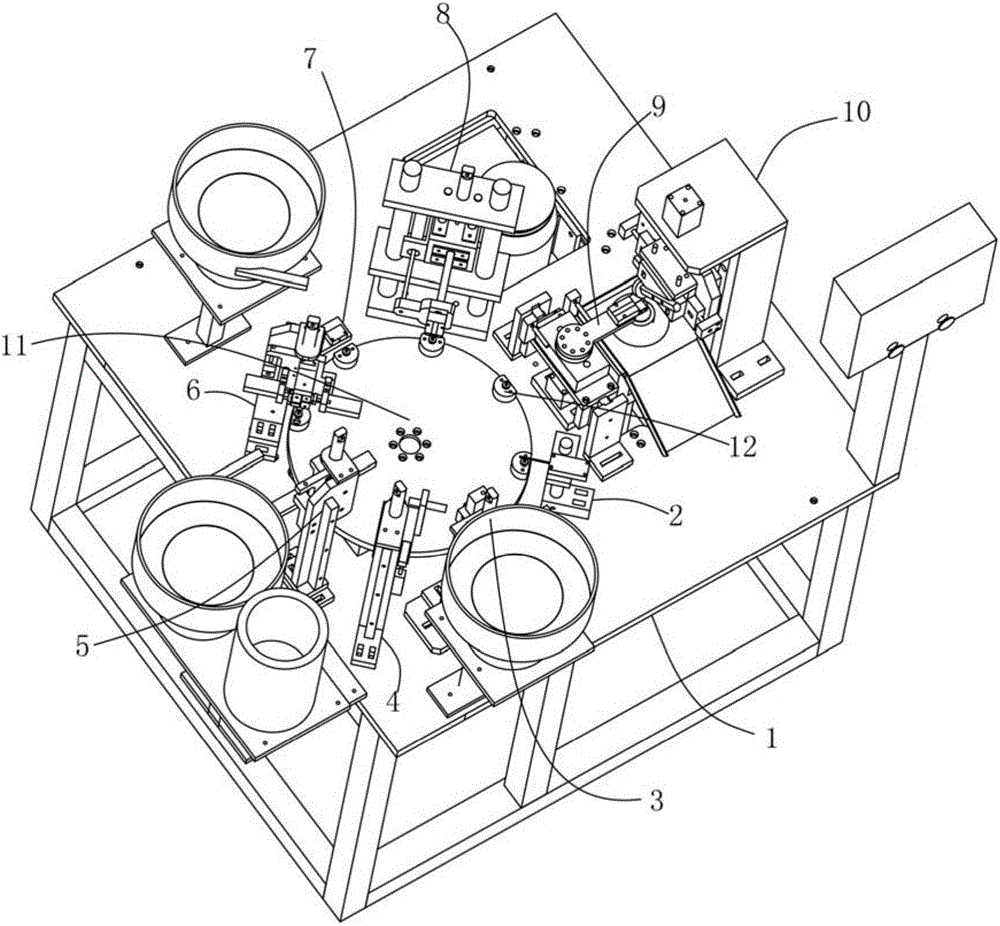

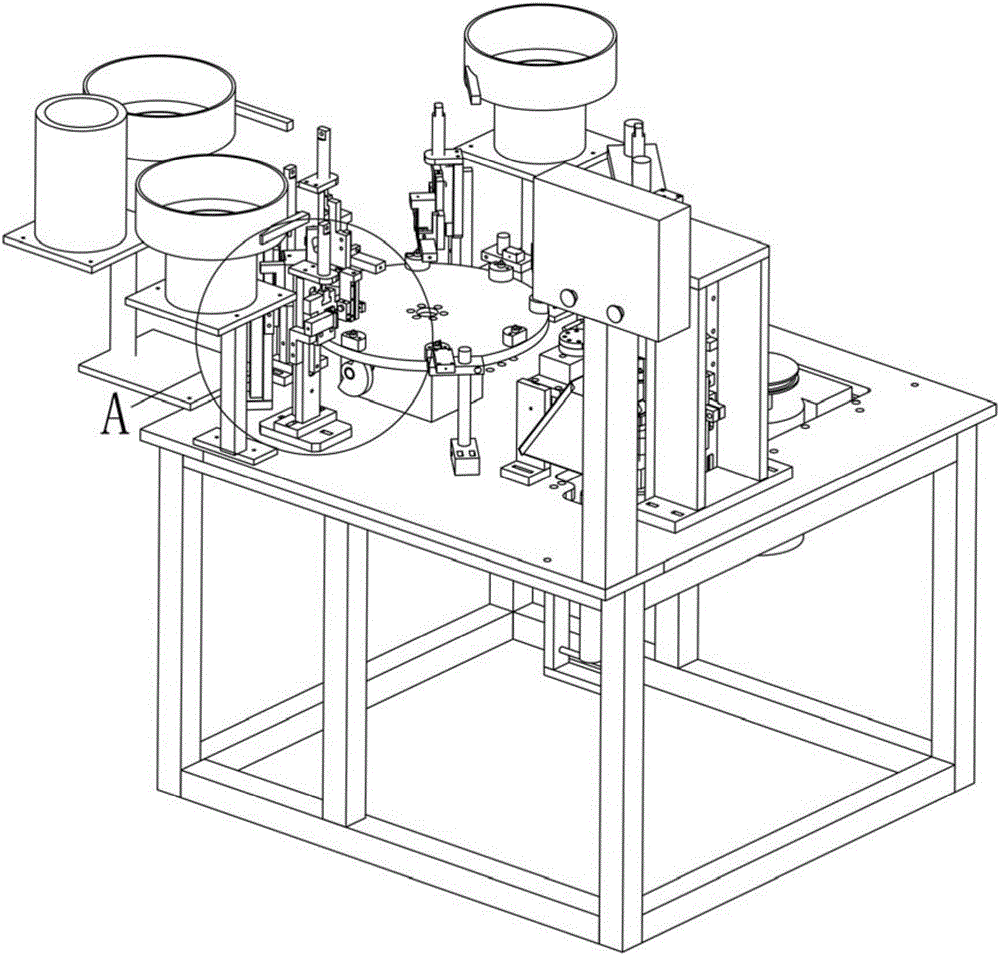

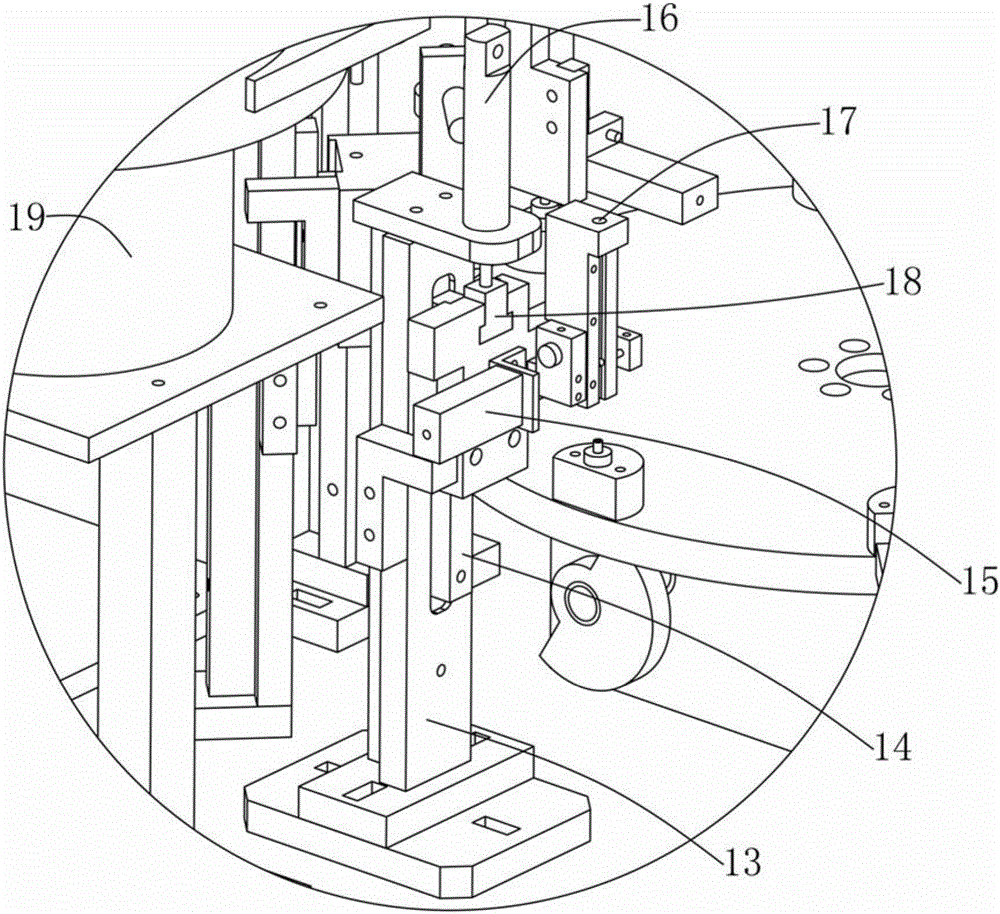

[0027] Such as Figure 1 to Figure 4 As shown, a needle valve automatic closing machine of the present invention includes a workbench 1, an induction switch 2, a needle valve automatic feeding mechanism 3, a detection mechanism 4, a spring feeding mechanism 5, a pin feeding mechanism 6, and an infrared detection mechanism. 7, a rotary feeding mechanism 9, a rolling riveting mechanism 10 and a turntable 11; the turntable 11 is rotatably installed on the workbench 1; the turntable 11 is provided with several positioning tooling 12 for tightening the needle valve; The induction switch 2, the needle valve automatic feeding mechanism 3, the detection mechanism 4, the spring un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap