Polishing method of glass sleeve for chalcogenide glass optical fiber preform prepared by tube rod method

An optical fiber preform and glass sleeve technology, which is applied in the polishing field, can solve the problems of no polishing method and polishing device, small inner hole size, long depth, etc., and achieve the effect of improving polishing effect, simple steps and good polishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the polishing method of the glass bushing for preparing the chalcogenide glass optical fiber preform by the pipe-and-rod method, comprising the following steps:

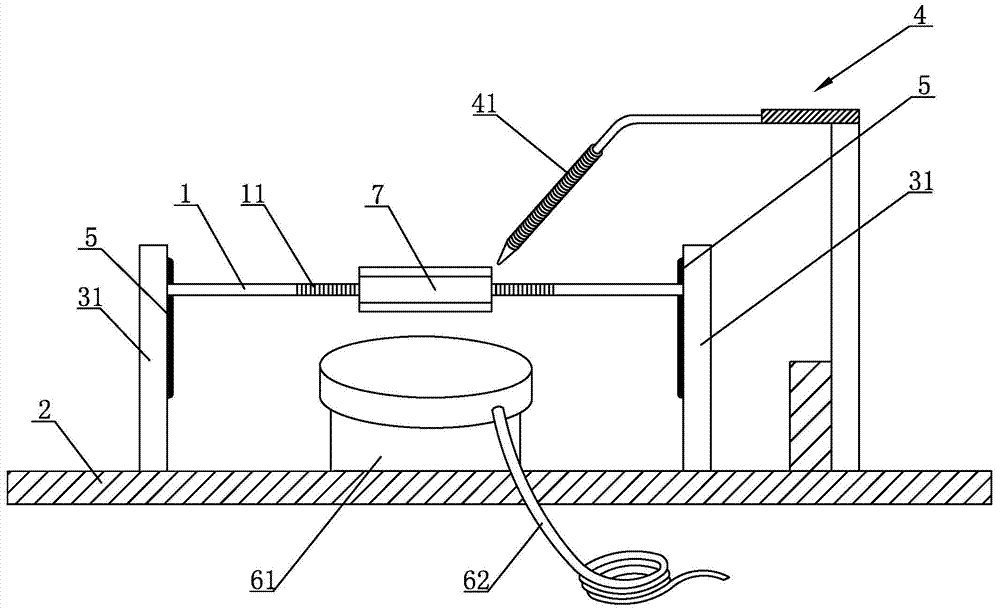

[0026] 1) Prepare a polishing device, such as figure 1As shown, the polishing device includes a high-hardness stainless steel round rod 1, a base 2, a fixing mechanism installed on the base 2, a cleaning mechanism 4 and a waste liquid recovery mechanism; the cleaning mechanism 4 is used to alternately provide inorganic polishing liquid and organic polishing The inorganic polishing liquid is distilled water, and the organic polishing liquid is a mixture of high-grade polishing powder and distilled water. The cleaning mechanism 4 is provided with a liquid outlet hose 41, and the liquid outlet angle of the liquid outlet hose 41 is adjustable; For reclaiming the polishing liquid, the waste liquid recovery mechanism includes a waste liquid bucket 61, which is connected with a liquid outlet conduit 62,...

Embodiment 2

[0031] Embodiment 2: the polishing method of the glass bushing used for preparing the chalcogenide glass optical fiber preform by the pipe-and-rod method, comprising the following steps:

[0032] 1) Prepare a polishing device, such as figure 1 As shown, the polishing device includes a high-hardness stainless steel round rod 1, a base 2, a fixing mechanism installed on the base 2, a cleaning mechanism 4 and a waste liquid recovery mechanism; the cleaning mechanism 4 is used to alternately provide inorganic polishing liquid and organic polishing The inorganic polishing liquid is distilled water, and the organic polishing liquid is a mixture of high-grade polishing powder and distilled water. The cleaning mechanism 4 is provided with a liquid outlet soft tube 41, and the liquid outlet angle of the liquid outlet hose 41 is adjustable; For reclaiming the polishing liquid, the waste liquid recovery mechanism includes a waste liquid bucket 61, which is connected with a liquid outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com