Fireproofing board manufacturing machine having automatic feeding function

A technology of automatic feeding and fireproof board, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems affecting the manufacturing quality of fireproof board, easy curing and water evaporation, etc., to reduce water loss and reduce gaps and bubbles, minus the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

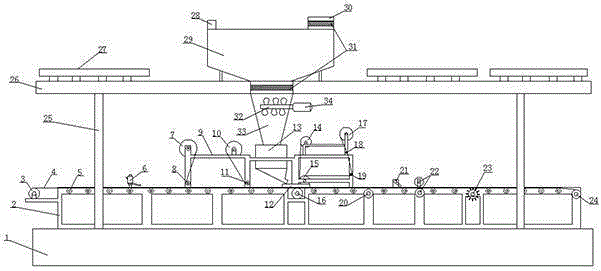

[0028] like figure 1 , image 3 The shown a kind of automatic feeding fireproof board manufacturing machine includes a frame 2 and a belt transmission device, the frame 2 is provided with a plurality of rolling rollers 5 equidistantly arranged in parallel, and the upper end surfaces of the plurality of rolling rollers 5 are At the same level, the frame 2 is located on the upper end of the rolling roller 5, and is sequentially provided with a dust removal device 6, a non-woven fabric rotating roller 7, a glass fiber rotating roller 10, a feeding funnel 13, a polytetrafluoroethylene film rolling roller 14, and a fireproof exterior decoration. Layer rolling roller 17, defoaming brush 21 and pressing device, the upper end of the frame 2 is also provided with a fixed frame 9, the non-woven fabric rotating roller 7, glass fiber rotating roller 10, feeding funnel 13, polytetrafluoroethylene Vinyl film rolling roller 14 and fireproof outer decoration layer rolling roller 17 are all a...

Embodiment 2

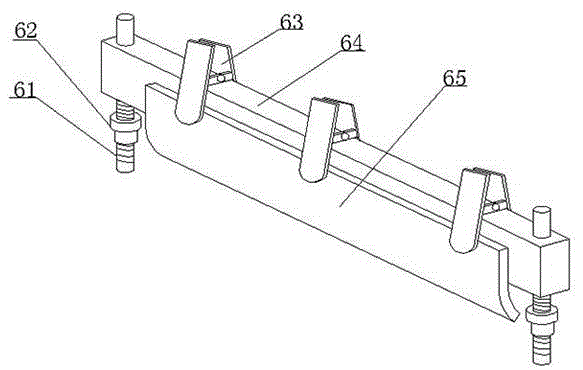

[0036] This embodiment adds the following structure on the basis of Embodiment 1: specifically: the lower ends of the non-woven fabric rotating roller 7, the glass fiber rotating roller 10 and the fireproof exterior decoration layer rolling roller 17 are respectively provided with The non-woven fabric pressing roller 8, the glass fiber pressing roller 11 and the fireproof exterior decoration layer pressing roller 19, the nonwoven fabric pressing roller 8, the glass fiber pressing roller 11 and the fireproof exterior decoration layer pressing roller 19 are all Located at the upper end of the rolling roller 5, the fixed frame 9 is located between the rolling roller 17 of the fireproof outer decoration layer and the pressing roller 19 of the fireproof outer decoration layer, and a buffer adjustment roller 18 is also provided.

[0037] The non-woven fabric pressing roller 8, the glass fiber pressing roller 11 and the fireproof outer decoration layer pressing roller 19 in the presen...

Embodiment 3

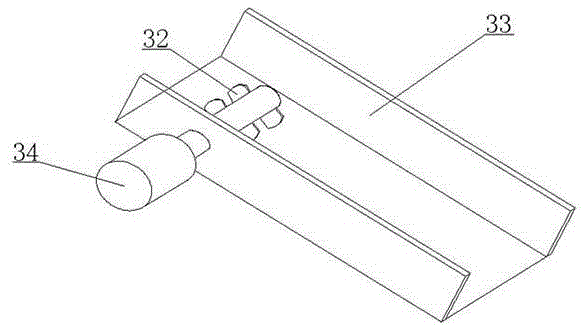

[0039] This embodiment is optimized as follows on the basis of embodiment 1 or embodiment 2: the mixer 29 includes a water inlet 28, a feed port 30 and a discharge port, and the feed port 30 and the discharge port are all provided with The filter screen 31, the discharge port is connected with the feed tank 33.

[0040] The stirrer 29 of the present embodiment is used for stirring and mixing the mixed slurry evenly, the water inlet 28 enters the water, the feed port 30 feeds the material, and the discharge port sends the mixed slurry and sends it into the feeding tank 33; Solid particles or incompletely mixed solid slurry enter the subsequent process and cause processing problems. In this embodiment, filter screens 31 are provided in the feed inlet 30 and the discharge port to filter the particles in the mixed slurry and improve the quality of the slurry. mixed precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com