Lightweight air chamber bracket of vehicle

A lightweight, air chamber technology, applied in the field of vehicles, can solve problems such as unreasonable structure and heavy weight, and achieve the effects of reducing machine cost, improving power performance, and reducing vehicle cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

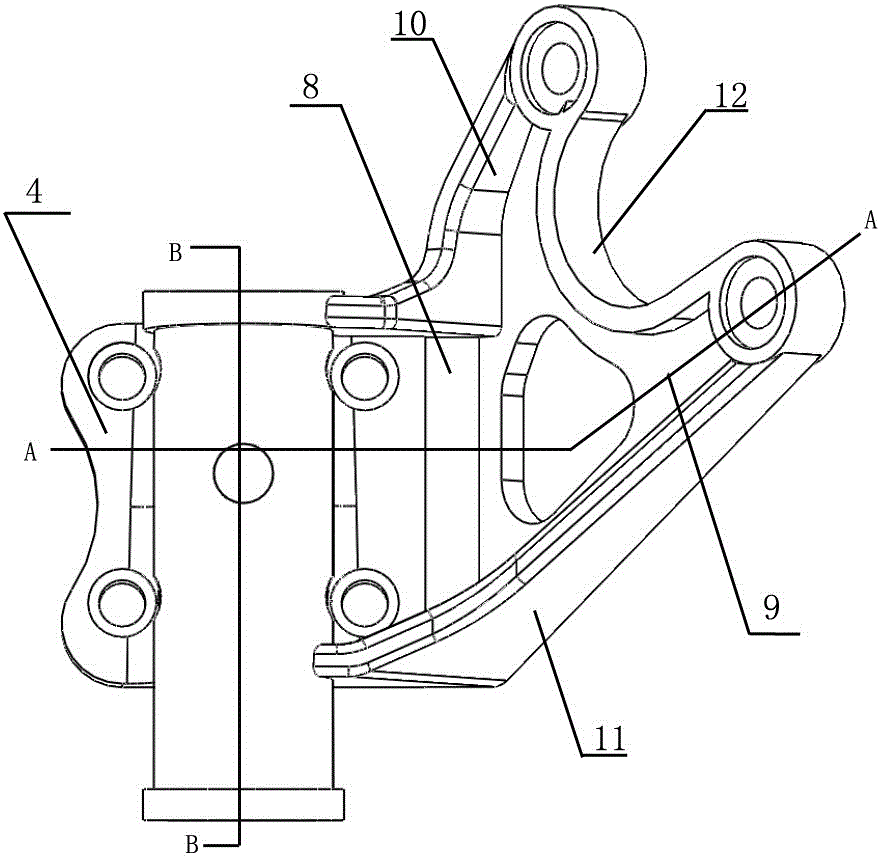

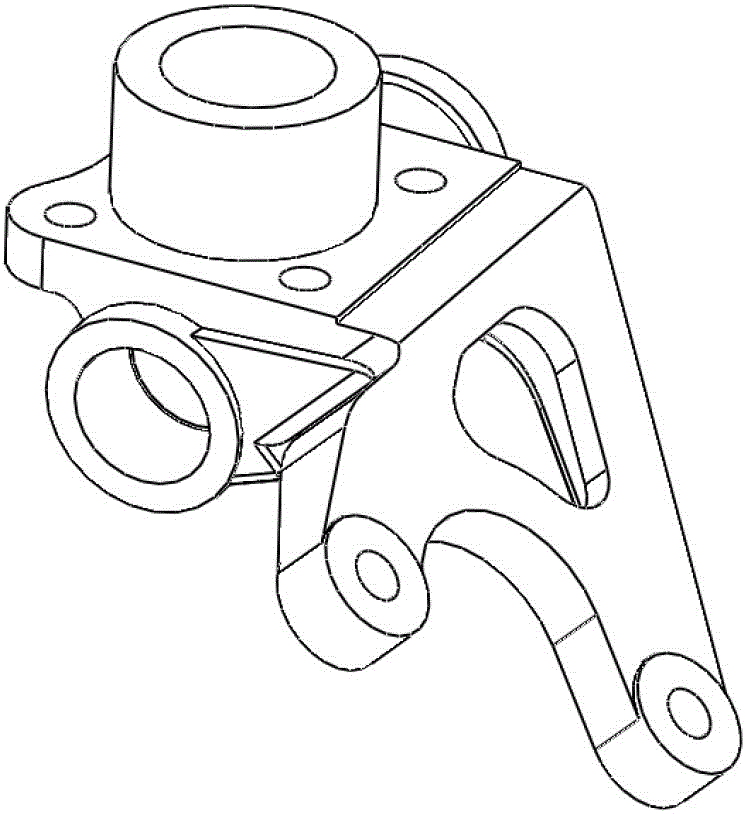

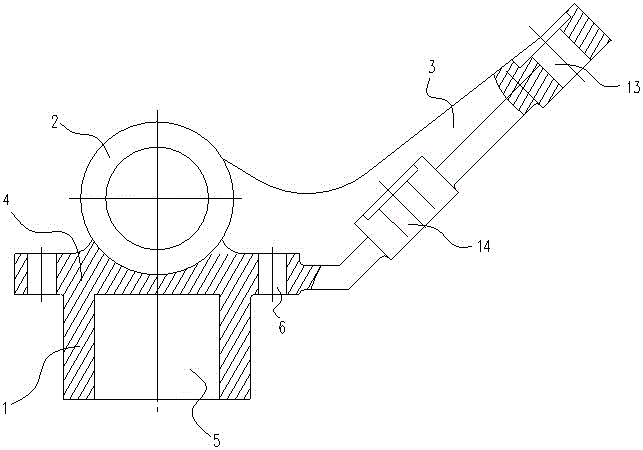

[0020] Such as figure 1 , 2 , Shown in 3 and 4, a light-weight air chamber support for automobiles, the air chamber support is integrally cast, and it includes a kingpin bearing seat 1, a camshaft bearing seat 2 and an air chamber mounting seat 3; the kingpin bearing seat 1 has A mounting part 4 for fixing the air chamber bracket and a hollow cylindrical part 5 arranged below the mounting part 4, the hollow cylindrical part 5 is used for installing the kingpin shaft, and an oil hole 16 is arranged on the cylindrical surface of the hollow cylindrical part 5 , the lower surface of the mounting part 4 is also provided with an air chamber bracket orientation pin hole 17 at a position close to the hollow cylindrical part 5, and 4 bolt holes 6 are provided on the mounting part 4; the camshaft bearing housing 2 has a hollow long cylindrical part 7. Set above the installation part 4, it is used to install the camshaft, and the connecting part between the installation part 4 and the c...

Embodiment 2

[0022] Such as figure 1 , 2 , Shown in 3 and 4, a light-weight air chamber support for automobiles, the air chamber support is integrally cast, and it includes a kingpin bearing seat 1, a camshaft bearing seat 2 and an air chamber mounting seat 3; the kingpin bearing seat 1 has A mounting part 4 for fixing the air chamber bracket and a hollow cylindrical part 5 arranged below the mounting part 4, the hollow cylindrical part 5 is used for installing the kingpin shaft, and an oil hole 16 is arranged on the cylindrical surface of the hollow cylindrical part 5 , the lower surface of the mounting part 4 is also provided with an air chamber bracket orientation pin hole 17 at a position close to the hollow cylindrical part 5, and 4 bolt holes 6 are provided on the mounting part 4; the camshaft bearing housing 2 has a hollow long cylindrical part 7. Set above the installation part 4, it is used to install the camshaft, and the connecting part between the installation part 4 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com