An ultrafiltration membrane unit for a water purifier

A technology of ultrafiltration membrane and water purifier, which is applied in the direction of ultrafiltration, osmosis/dialysis water/sewage treatment, etc. It can solve the problems of increasing the cost of water purifier, the quality of washing cannot be guaranteed, and the ultrafiltration membrane is easy to be blocked. Improve flushing effect, save material cost and service cost, and facilitate popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

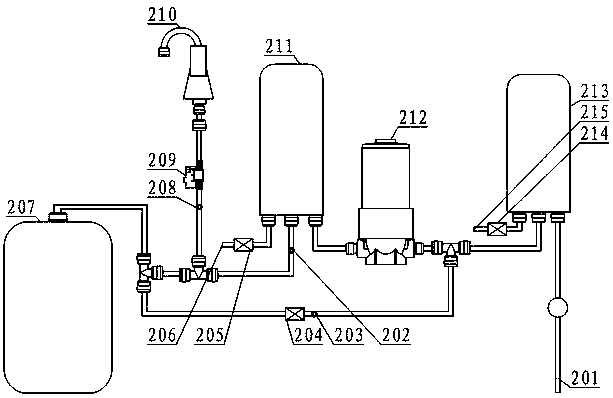

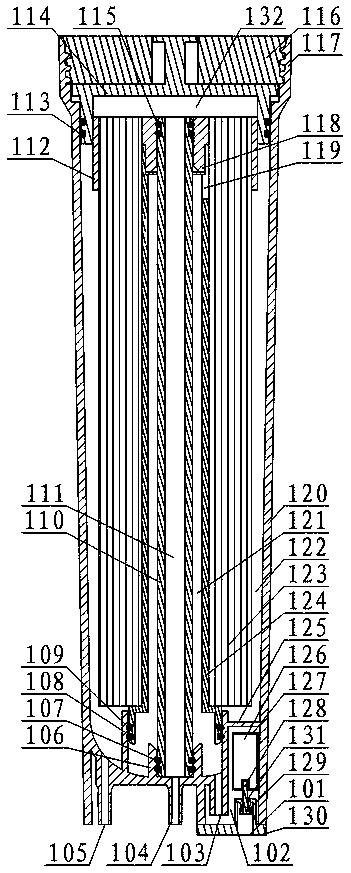

[0021] Such as figure 1 As shown, a water purifier includes a water inlet pipe 201, a solenoid valve 1 204, a pressure water storage tank 207, a reverse osmosis membrane filter group 211, a booster pump 212, an ultrafiltration membrane filter group 213, a solenoid valve 3 214 and a flushing pipe Road, wherein, the ultrafiltration membrane filter group 213 is provided with a water suction port 103, a filtered water outlet 104 and a water discharge port 105, the water inlet pipe 201 is connected with the water suction port 103 of the ultrafiltration membrane filter group 213, and the water outlet of the ultrafiltration membrane filter group 213 105 is connected with flushing water pipe 2 215, solenoid valve 3 214 is arranged on flushing water pipe 2 215, booster pump 212 adopts a booster pump with self-priming capability, and its inlet is connected with filtered water outlet 104 of ultrafiltration membrane filter group 213. The reverse osmosis membrane filtration group 211 of th...

Embodiment 2

[0024] This embodiment makes the following further limitations on the basis of Embodiment 1: this embodiment is also equipped with a one-way valve two 203 during specific settings, wherein the one-way valve two 203 is set on the flushing pipeline and controls the flow of water from the electromagnetic The valve one 204 communicates with the outlet end of the flushing pipeline in one direction.

Embodiment 3

[0026] This embodiment makes the following further limitations on the basis of embodiment 1 or embodiment 2: this embodiment is also equipped with a one-way valve 202 during specific settings, wherein the one-way valve 202 is connected to the reverse osmosis membrane filter At the water purification outlet of the group 211, and the water flow through the water purification outlet of the reverse osmosis membrane filtration group 211 is controlled to circulate in one direction from the inside of the reverse osmosis membrane filtration group 211 to the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com