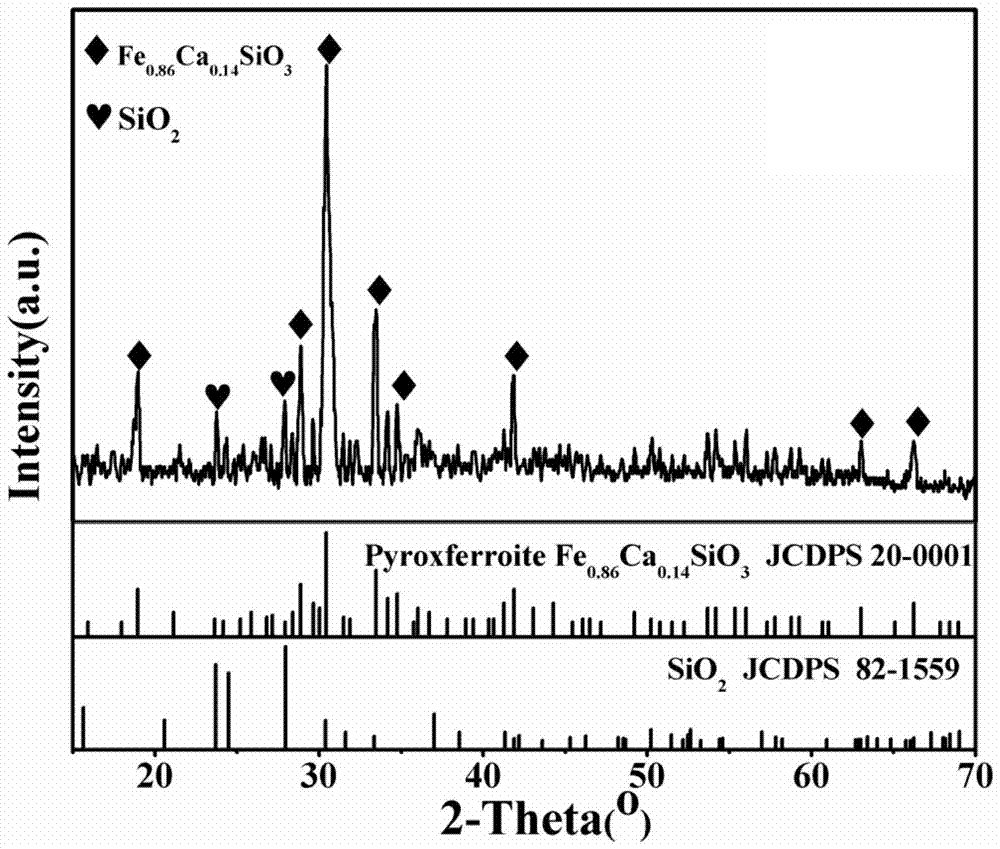

A kind of glass-ceramic containing triclinic iron pyroxene crystal phase and its preparation method

A technology of triclinic pyroxene and glass-ceramics, which is applied in the field of preparation of bioactive glass-ceramics, and can solve the problems that there are no relevant reports on the preparation of triclinic pyroxene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Combine analytically pure calcium carbonate, analytically pure boric acid, SiO 2 , CeO 2 and Sb 2 o 3 Mixing, so that meet according to mass parts, the CaO of 20 parts, the Fe of 20 parts 2 o 3 , 40 copies of B 2 o 3 , 20 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0030] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1250°C for melting to form molten glass, and keep warm at 1250°C for 1 hour to obtain a clear and homogeneous molten glass;

[0031]Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool down to room temperature with the furnace to obtain calcium-iron-borosilicate glass;

[0032] Step 4: Cut the prepared calcium-iron-borosilicate glass into a certain shape, place the cut sample on an alumina...

Embodiment 2

[0037] Step 1: Combine analytically pure calcium carbonate, analytically pure boric acid, SiO 2 , CeO 2 and Sb 2 o 3 Mixing, so that meet according to mass parts, the CaO of 20 parts, the Fe of 20 parts 2 o 3 , 30 copies of B 2 o 3 , 30 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0038] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1300°C for melting to form molten glass, and keep warm at 1300°C for 1 hour to obtain a clear and homogeneous molten glass;

[0039] Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool to room temperature with the furnace to obtain calcium-iron-borosilicate glass;

[0040] Step 4: Cut the prepared calcium-iron-borosilicate glass into a certain shape, place the cut sample on an alumina pla...

Embodiment 3

[0042] Step 1: Combine analytically pure calcium carbonate, analytically pure boric acid, SiO 2 , CeO 2 and Sb 2 o 3 Mixing, so that meet according to mass parts, the CaO of 20 parts, the Fe of 20 parts 2 o 3 , 20 copies of B 2 o 3 , 40 parts of SiO 2 , 0.3 parts of CeO 2 and 0.2 parts of Sb 2 o 3 , mixed evenly to obtain the batch material;

[0043] Step 2: Add the uniformly mixed batch material into a corundum crucible at 1100°C, heat up to 1350°C for melting to form molten glass, and keep warm at 1350°C for 1 hour to obtain a clear and homogeneous molten glass;

[0044] Step 3: Quickly pour the evenly melted molten glass onto a stainless steel plate, transfer it to an annealing furnace at 500°C immediately after forming, keep it warm for 2 hours, and then cool to room temperature with the furnace to obtain calcium-iron-borosilicate glass;

[0045] Step 4: Cut the prepared calcium-iron-borosilicate glass into a certain shape, place the cut sample on an alumina pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com