Manufacturing process for high-toughness forged and pressed anti-abrasion liner plates

A wear-resistant lining plate and manufacturing process technology, which is applied in the field of high-toughness forging wear-resistant lining plate manufacturing technology, can solve the problems of affecting the service life of the lining plate, many impurities, low impact toughness, etc., so as to reduce production costs, reduce pollution, reduce The effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

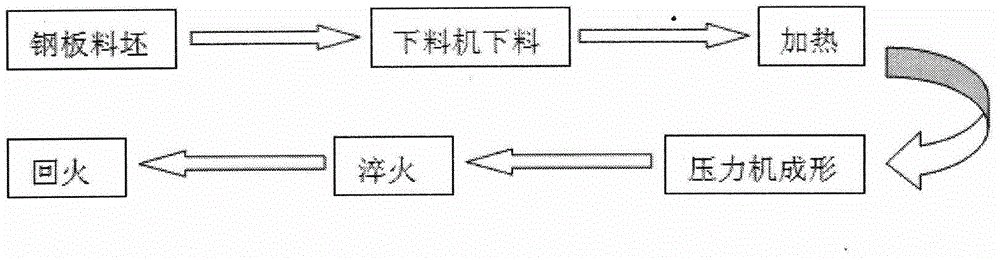

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. The invention discloses a high-toughness forged wear-resistant liner manufacturing process, which includes the following steps: steel plate - cutting and blanking - forging - machining - quenching - tempering - inspection - finished product;

[0017] 1. The steel plate is cut, blanked and forged according to the size of the lining plate.

[0018] 2. The forging temperature is 950-1000°C, and heat preservation and slow cooling are carried out after forging;

[0019] 3. Machined bolt holes, grid plates and other parts, and the raised parts can be welded by resistance welding;

[0020] 4. Heating to 780--900°C with an electric furnace, and heat preservation treatment, after being out of the furnace at 750-850°C, quenching with water-based quenching liquid;

[0021] 5. Tempering at 200-320°C after quenching;

[0022] 6. Carry out grinding and inspection to obtain a high-performance forged lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com