Process for electroplating sand nickel on automobile heat-dissipation grating

A technology of heat dissipation grille and electroplating process, applied in jewelry and other directions, can solve the problems of poor brightness and softness of pearl nickel coating, and achieve the effect of being conducive to chemical bonding, improving bonding force and long service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

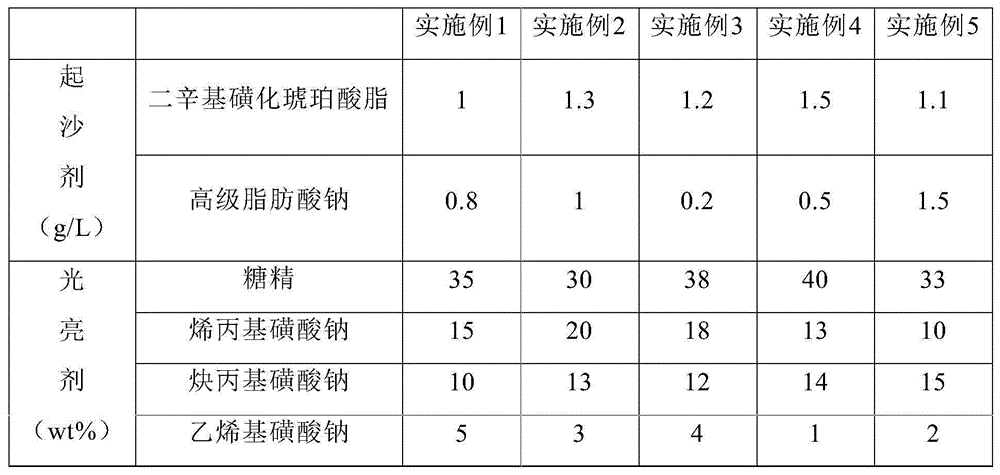

Examples

Embodiment Construction

[0055] The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the manufacturer's conditions, and the unspecified implementation conditions are usually conventional experimental conditions.

[0056] A kind of sandy nickel electroplating process of automobile radiator grille according to the present invention comprises the following steps:

[0057] 1) Degreasing

[0058] Carry out degreasing and dust removal treatment on the surface of the plastic substrate of the injection-molded automobile radiator grille, and then put it into the cleaning tank and rinse it with water;

[0059] 2) coarsening

[0060] Send the plastic substrate into the roughening liquid tank for roughening treatment, then put it into the cleaning tank and rinse it with clean water. The roughening temperature is 50-60°C, and the roughening ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com