Anti-cutting cladding yarn and preparation method and purpose

A cut-resistant and yarn-resistant technology, which is applied in yarns, applications, textiles and papermaking, etc., can solve the problems of insufficient cut resistance and thermal contact resistance, insufficient wear resistance, difficulty in cutting resistance and thermal contact resistance, etc., to achieve Excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

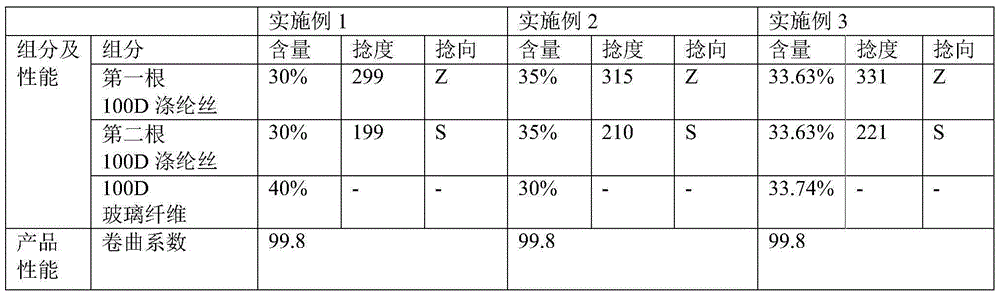

[0046] Embodiments 1 to 3 provide a covered yarn and its preparation method. The preparation method is to use 100D glass fiber as the core thread, and wrap the core thread with two wound 100D polyester filaments. Specifically The parameters are shown in Table 1;

[0047] The performance of the covered yarn obtained in the above-mentioned embodiments 1 to 3 is detected, and the results are shown in Table 1;

[0048] Table 1

[0049]

Embodiment 4~6

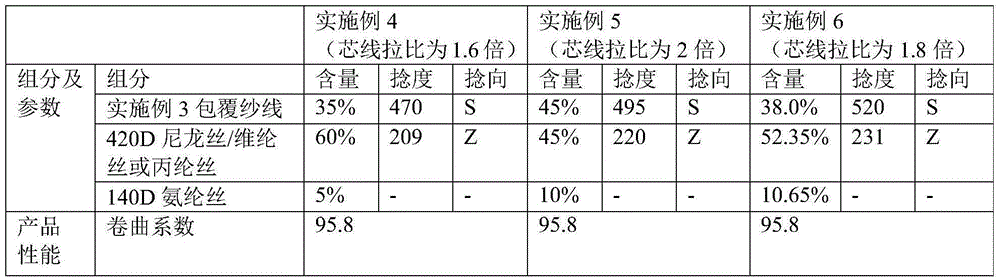

[0051] Embodiments 4 to 6 provide a cut-resistant coated yarn based on the covered yarn described in Example 3 and a preparation method thereof, using 140D spandex yarn as the core thread, and wrapping the yarn described in Example 3 after winding Yarn, 420D nylon filament or vinylon or polypropylene fiber is coated on described core thread, obtains, and specific parameters are shown in Table 2;

[0052] The performance of the coated yarn obtained in the above-mentioned Examples 4-6 is detected, and the results are shown in Table 2;

[0053] Table 2

[0054]

Embodiment 7~9

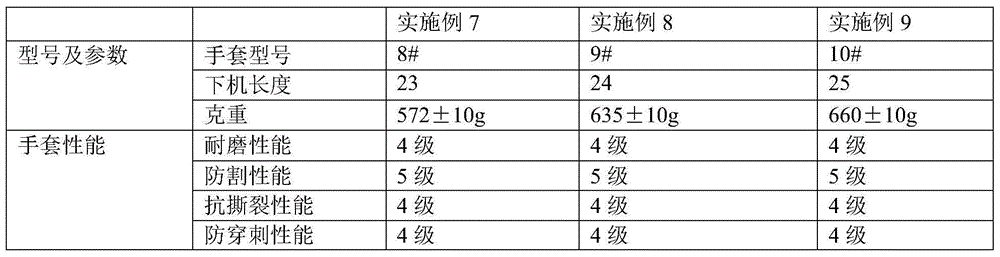

[0056] Embodiments 7 to 9 provide a glove woven with the cut-resistant covered yarn described in Embodiment 6. The glove is woven using a 13-needle knitting machine. The type, parameter setting and performance test of the glove are shown in Table 3 :

[0057] table 3

[0058]

[0059]

[0060] When knitting 8# gloves, control the number of gyrations of the little finger to 58, the number of gyrations of the ring finger to 78, the number of gyrations of the middle finger to 84, the number of gyrations of the index finger to 74, the number of gyrations of the thumb to 35, and the number of gyrations of the four fingers is 56, the number of turns of the five-fingered palm is 38, and the number of turns of the thread portion is 76.

[0061] When knitting 9# gloves, control the number of turns of the little finger to 60, the number of turns of the ring finger to 80, the number of turns of the middle finger to 56, the number of turns of the index finger to 76, the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com