A polygonal modular house box with plate unit

A modular and polygonal technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor corrosion resistance, difficult to expand the internal space, complex molding process, etc., to achieve excellent mechanical and corrosion resistance, Broad application prospects and economic benefits, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

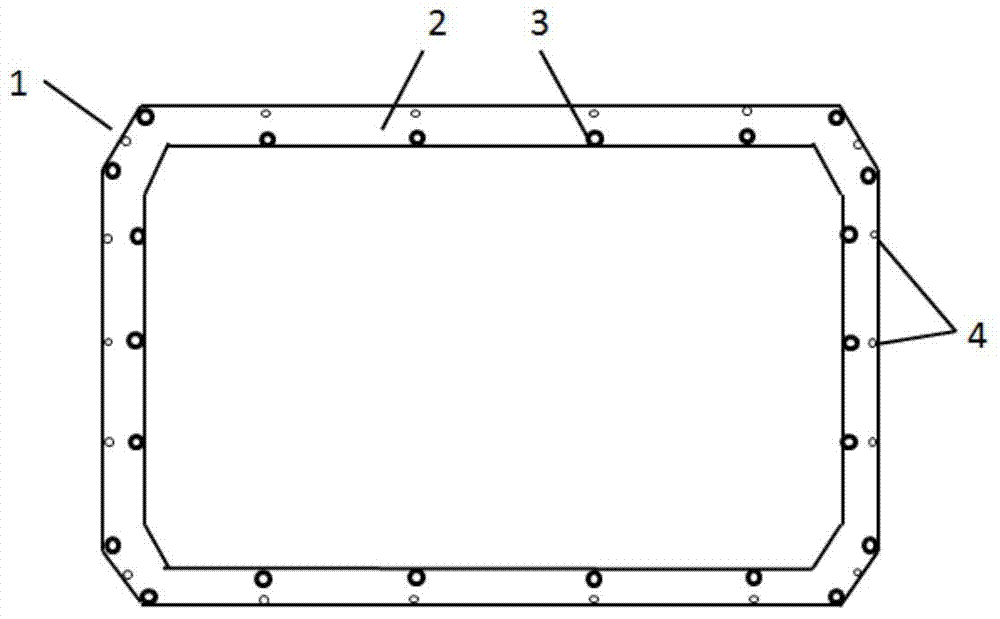

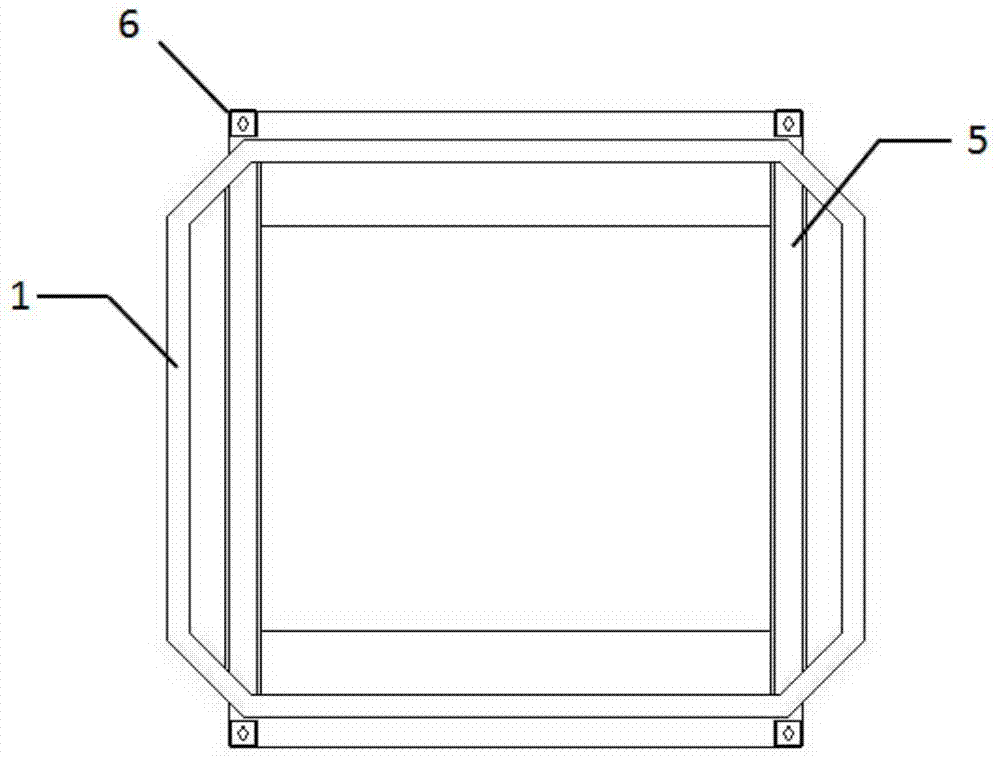

[0033] The preparation process of the plate unit 1 is as follows: the plate-shaped base material is sent to the conveying device, and the distance between adjacent cutting corners, the diameter of the punching hole and the transmission speed are set according to the shape of the required room box, and the processing equipment is started. The material advances on the conveying device, and the punching, corner cutting, rolling, and cutting processes are performed in sequence to obtain the plate unit base material; the width of the plate base material is 60-80cm, and the diameter of the pipeline hole in the punching process is 15-22cm . The chamfering can be triangular chamfering, arc chamfering or other common chamfering shapes, and the width of the flanging part during the rolling process is 8-15cm.

[0034] After finishing making board unit 1, see image 3 , fold upwards along the rolling lines AA', BB' to form the flanging part 2, and then fold upwards along the center line ...

Embodiment 1

[0039] Such as Figure 1-4 As shown, the galvanized aluminum sheet is sent to the conveying device, the distance between adjacent cut corners, the diameter of the punching hole and the transmission speed are set, the processing equipment is started, the galvanized aluminum sheet advances on the conveying device, and punching, corner cutting, and rolling are performed in sequence. The plate unit base material is obtained through the manufacturing and cutting process; the width of the plate base material is 60cm, and the diameter of the pipeline hole in the punching process is 20cm. The corner cutting can be an arc-shaped corner cutting, and the width of the flanging part during the rolling process is 10cm.

[0040] After finishing making board unit 1, see image 3 , turn up along the rolling line AA', BB' to form the flanging part 2, and then turn up along the center line CC' of the alignment chamfer to finally form a closed ring structure, and connect the two ends of the plat...

Embodiment 2

[0042] Such as Figure 5 As shown, the double-layer combined modular room box of the present invention is that a plurality of modular room boxes are connected with hinged rings through the hinge unit 6, and windows are provided in each room box, and external stairs and external corridors are included. The modular room box is composed of anti-corrosion metal plate, thermal insulation layer, heat insulation aluminum foil layer and decorative layer from the wall panel to the inside, and windows can also be opened on the wall panel of the room box.

[0043] The combined modular room box can also be arranged and combined into various shapes according to actual needs to meet actual needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com