Intelligent control system of pattern sewing machine

An intelligent control system and technology for pattern sewing machines, applied in the field of control systems, can solve the problems of inability to meet pattern sewing machines, affect control speed, and limited computing accuracy, and achieve the effects of shortening training cycles, reducing work intensity, and improving sewing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

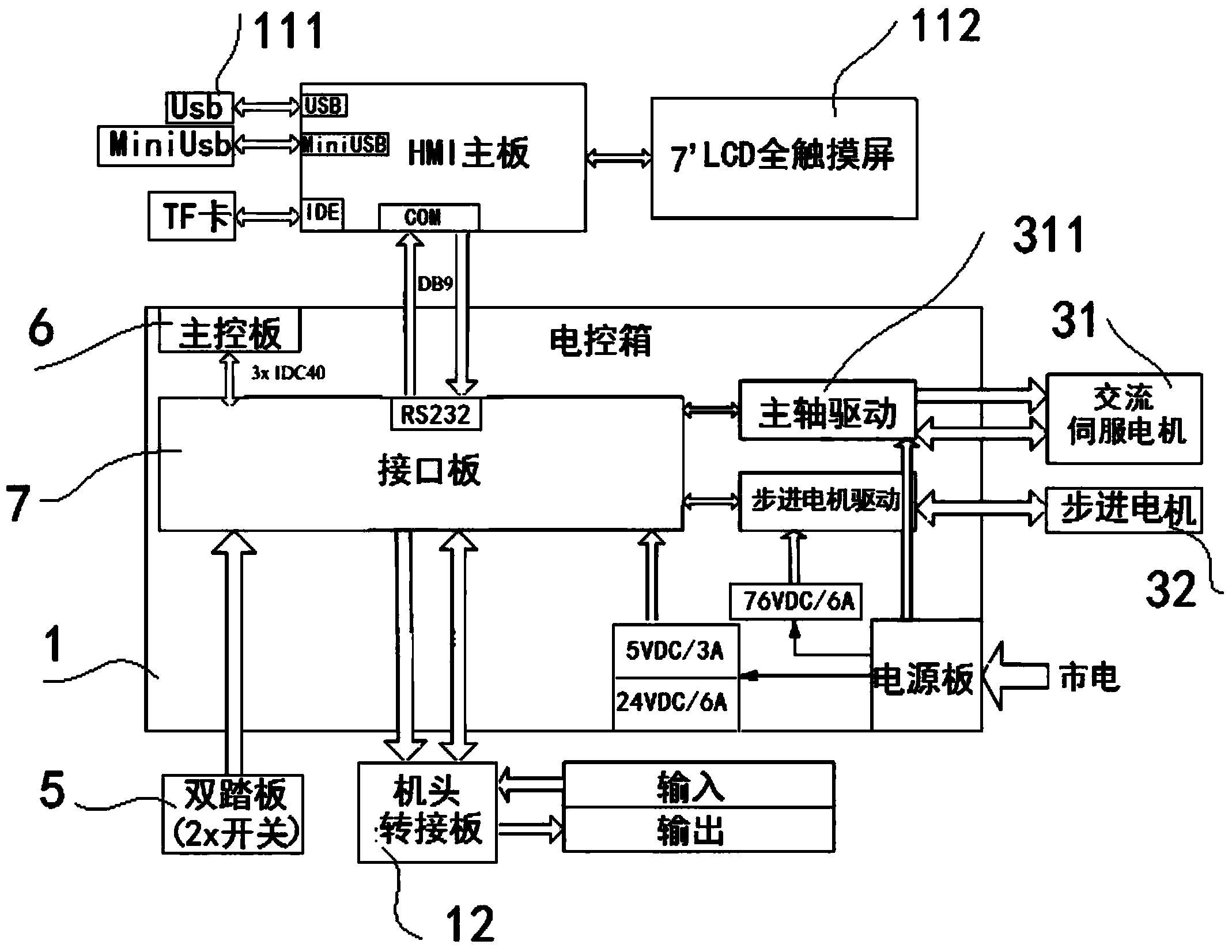

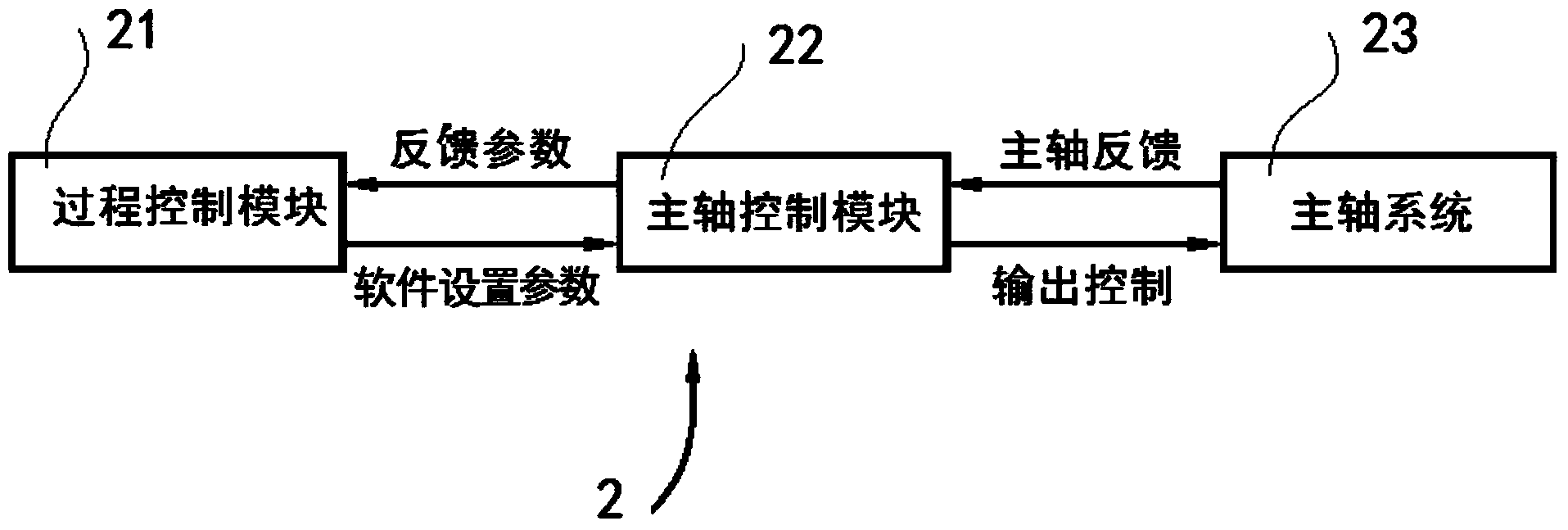

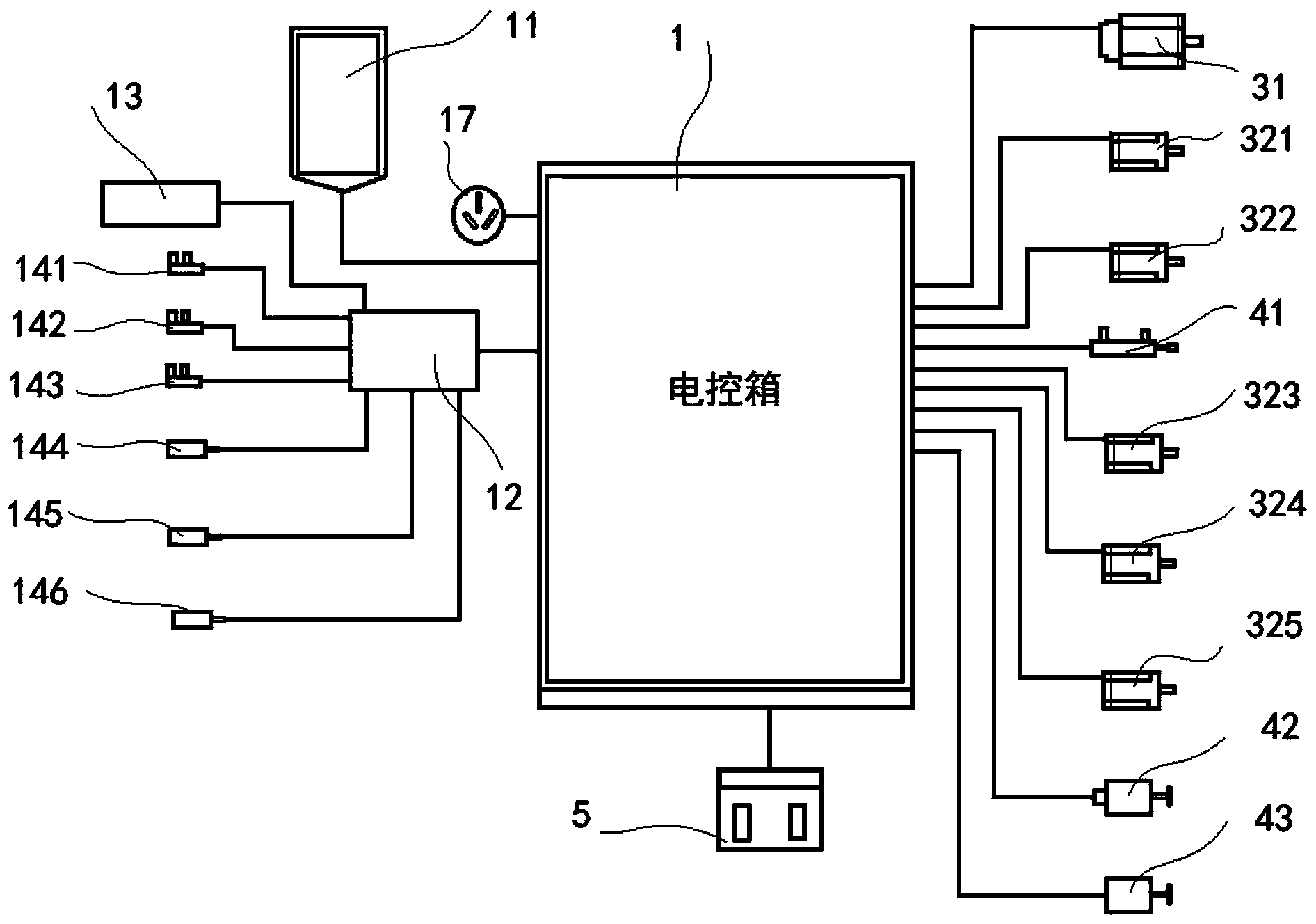

[0028] Example: such as figure 1As shown, an intelligent control system of a pattern sewing machine includes a software system, a hardware system and a structural system. The structural system includes the electric control box 1, and the hardware system includes the spindle control subsystem and the subsystems that control the needle bar mechanism, thread hooking mechanism, thread take-up mechanism, feeding mechanism and presser foot mechanism. The spindle control subsystem is equipped with a position closed-loop control movement Control module and spindle system fault handling and enabling control module 2; the needle bar mechanism, thread hooking mechanism and thread take-up mechanism are controlled by AC servo motors, the feeding mechanism is controlled by an XY motor composed of two stepping motors, and the thread take-up mechanism and the presser foot mechanism are each controlled by a stepping motor; the core of the hardware system is composed of DSP+ARM dual-core system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com