Steel wire brush drill rotor rotor rotor and solve the method of buried drills, drilling, and stuck drills

A wire brush and drill bit technology, applied in the field of basic engineering, can solve problems such as harsh noises, crane overturning, uncertainty, etc., and achieve the effects of overcoming the influence of buoyancy, ensuring quality, and expanding the applicable field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

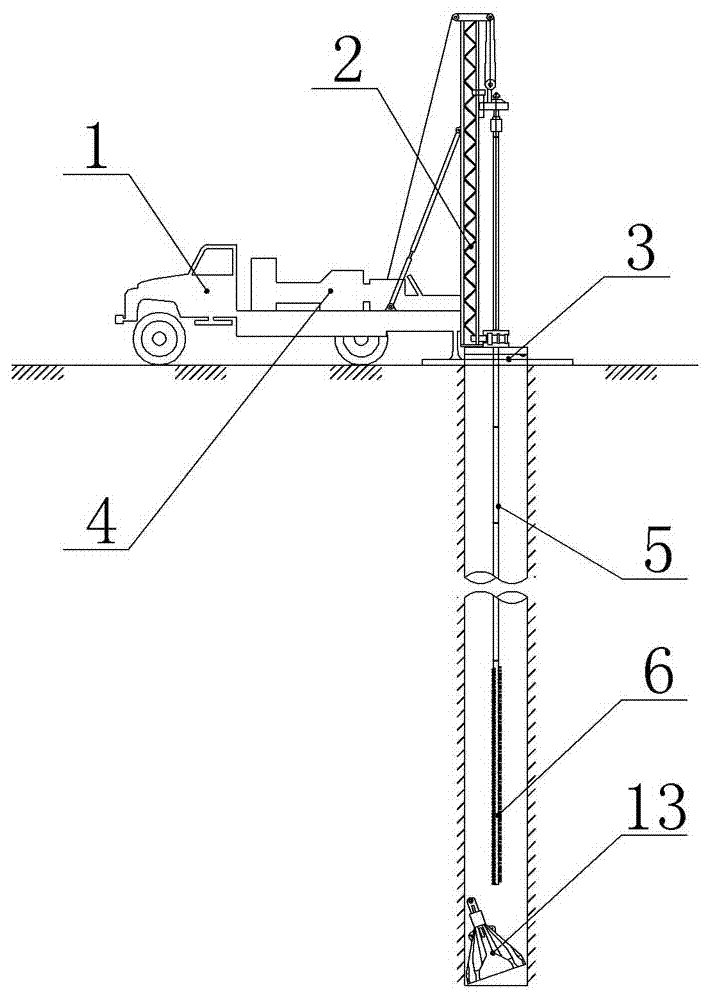

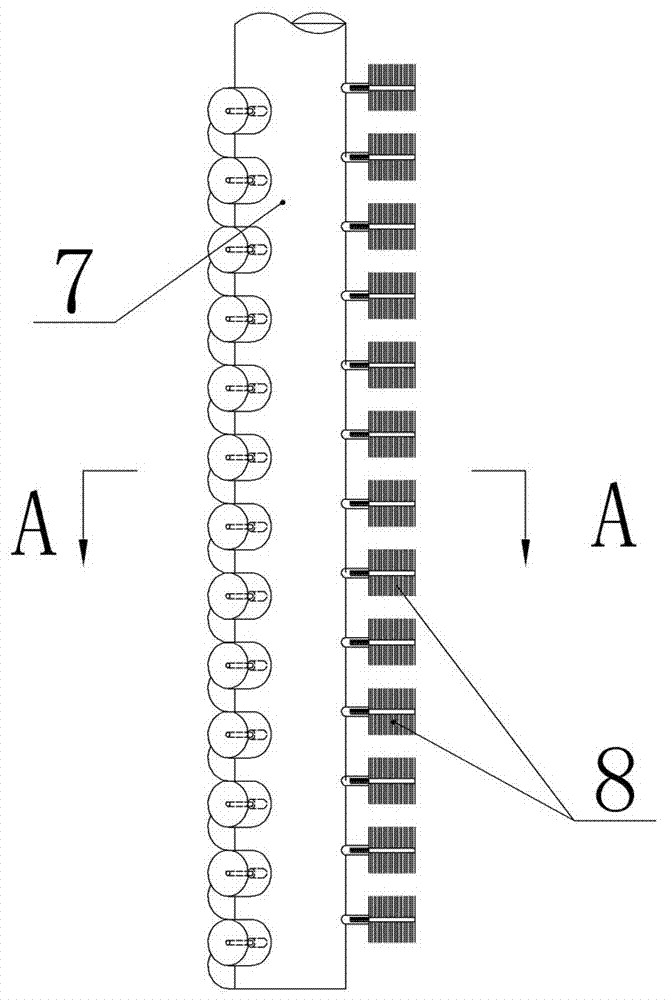

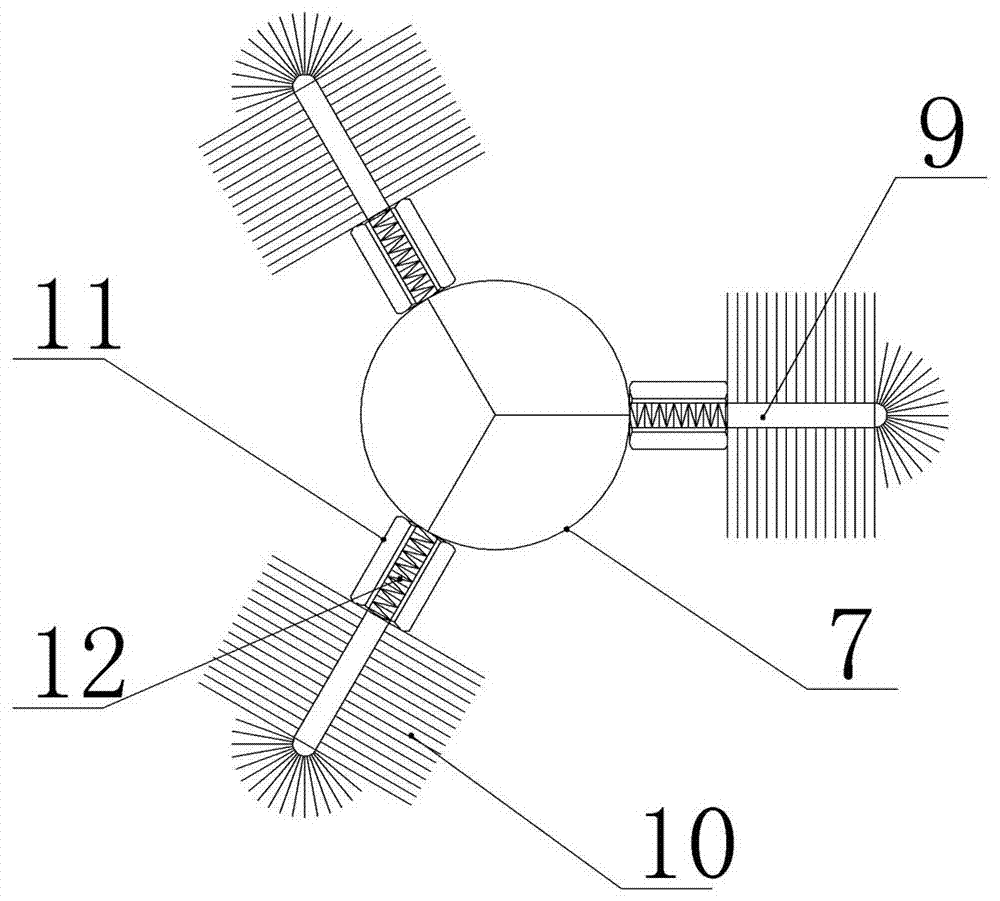

[0040] Embodiment one: see Figure 1-Figure 4 , a wire brush drill bit rotary drilling rig according to the present invention, comprising auxiliary walking and transportation equipment 1, a power mechanism 4 is arranged on the auxiliary walking and transportation equipment 1, a drill frame 2 is arranged corresponding to the well hole, a rotary Well frame 3, hollow drill pipe 5 and wire brush drill bit 6, described auxiliary walking and transportation equipment 1 is automobile or power tricycle, and described wire brush drill bit length is 4m~6m, and described wire brush drill bit 6 includes Solid drill rod 7 and the steel wire brush 8 that is fixedly distributed on the solid drill rod 7, described steel wire brush 8 comprises the steel wire brush body 9 that is fixedly connected with solid drill rod 7 and the steel wire 10 that implants steel wire brush body 9, so The steel wire brush body 9 described above is a multi-strand twisted steel wire rope with a certain rigidity, and...

Embodiment 2

[0042] Embodiment two: see Figure 1-Figure 4 , a method for solving buried, dropped, and stuck drills using the wire brush drill bit rotary drilling rig described in Embodiment 1, for the situation of buried drills, dropped drills, or stuck drills in the drill bit of the drilling rig during the construction process, carry out the salvage of the drill bit Operation, first check the design drawings, find out the hydrogeological conditions, check the construction hole records, ask and investigate the operators, determine the cause of the accident and the corresponding depth of the drill bit, and carry out the following salvage steps:

[0043] ① Put the wire brush drill bit rotary drilling rig in place in the well hole, connect the drill pipe and the wire brush bit until it reaches the accident location, and then slowly drill in to observe the resistance, difficulty, and amount of footage received by the drilling rig, until until the footage cannot be continued;

[0044] ② Lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com