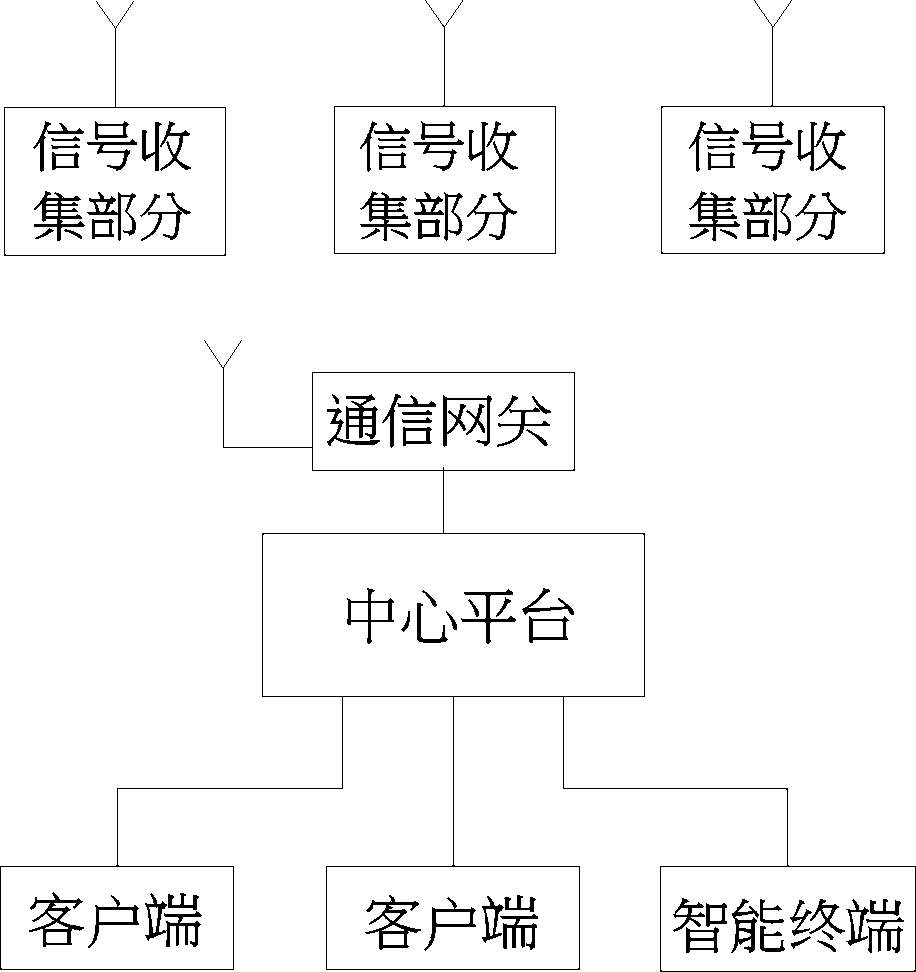

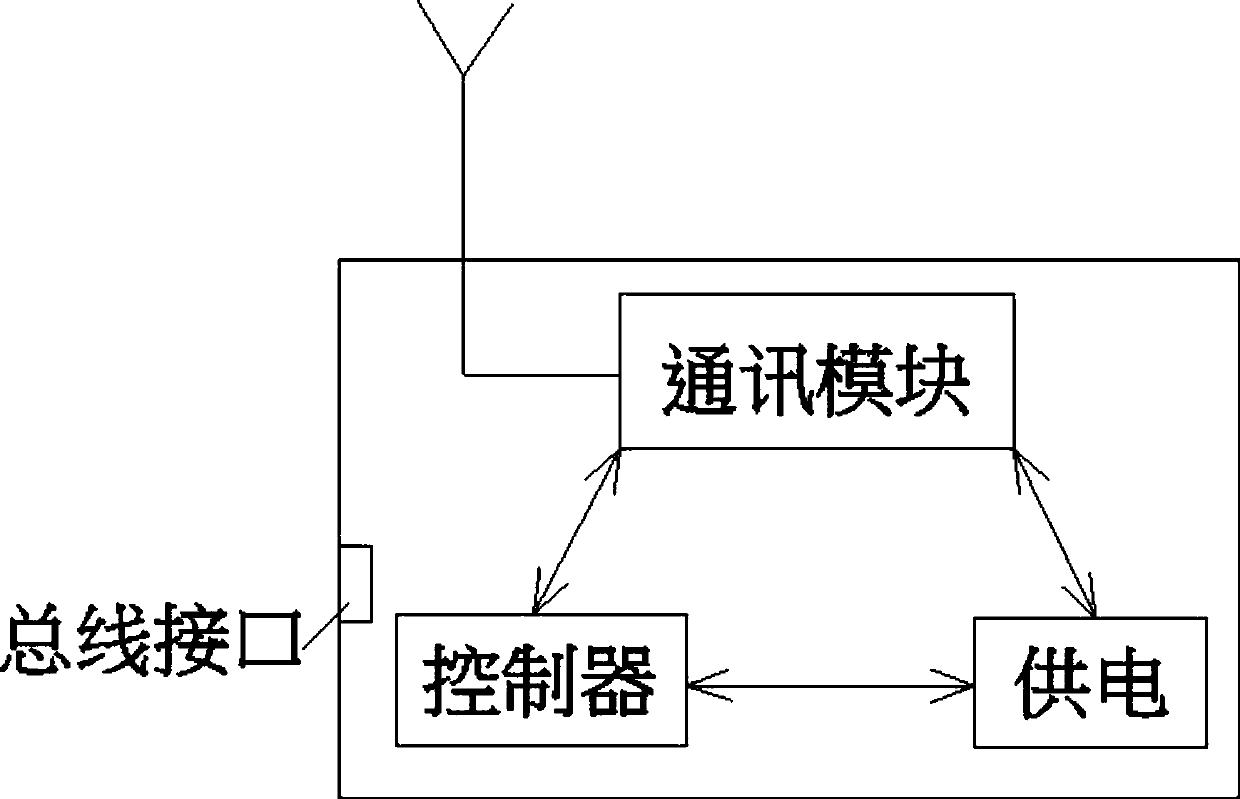

Single-core high-voltage cable joint intelligent monitoring system and intelligent monitoring method

A high-voltage cable, intelligent monitoring technology, applied in measuring devices, measuring heat, measuring electrical variables, etc., can solve the problems of incomplete parameter analysis method, incomplete monitoring data, cable explosion, etc., to prevent untimely reporting of parameters or Inaccurate, accurate cable operating conditions, and the effect of saving misrepair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

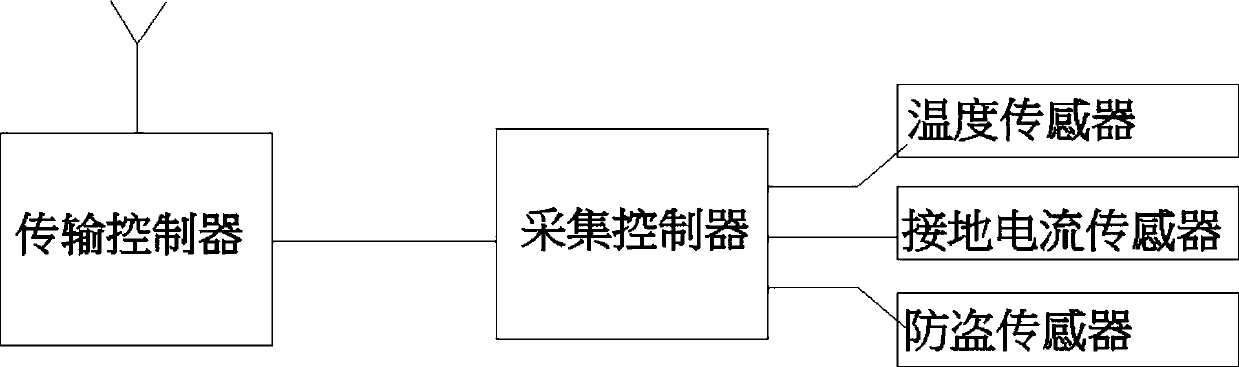

[0100] For cable temperature monitoring:

[0101] Preset the temperature comparison value in the acquisition controller: the ambient temperature T1, the cable surface temperature T2, and the core temperature T3 are all <60°C, the first difference ΔT21<5°C, the second difference ΔT32<10°C; and : A change in the first difference ΔT21 greater than 5°C within 1 hour is considered abnormal; a rise of 5°C within 1 hour for T2 and T3 is considered abnormal.

[0102] The acquisition controller collects data every 5 minutes. The current collected data is that the ambient temperature T1 is 25°C, the cable surface temperature T2 is 27°C, and the core temperature T3 is 29°C; and calculate the first difference ΔT 21 =2°C, everything is within the normal data; then the data is transmitted to the central platform every 12 hours.

[0103] For ground wire current monitoring:

[0104] In the acquisition controller, the preset value of the grounding current of the three-phase wires connected t...

Embodiment 2

[0115] For cable temperature monitoring:

[0116] The acquisition controller collects data every 5 minutes. The current collected data is that the ambient temperature T1 is 25°C, the cable surface temperature T2 is 31°C, and the core temperature T3 is 32°C; and calculate the first difference ΔT 21 =4℃, the second difference ΔT 32 =3°C, where the first difference is ΔT 21 =6℃ is an abnormal value

[0117] The collection controller shortens the data collection time to once every 2 minutes.

[0118] The data collected three times in a row is in an abnormal state, and the collector immediately sends the abnormal state data to the central platform. And send data to the central platform every 4 minutes thereafter.

[0119] The central platform issues early warnings to clients and smart terminals.

[0120] For ground wire current monitoring:

[0121] The acquisition controller collects the A-phase ground current I1A=61; the B-phase ground current I1B=62, and the C-phase ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com