Optical diaphragm, backlight module and display device

An optical film and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of not being able to provide light focusing effect and anti-scratch, shielding and other properties at the same time, high haze of lens structure, anti-scratch It can improve the light transmittance, good shading, and high light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

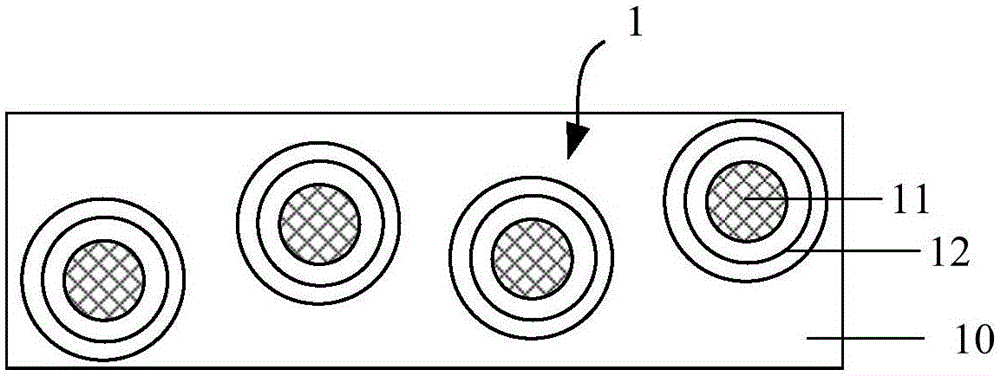

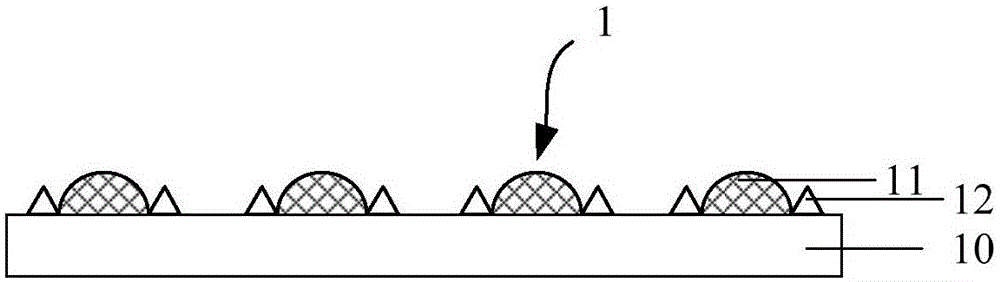

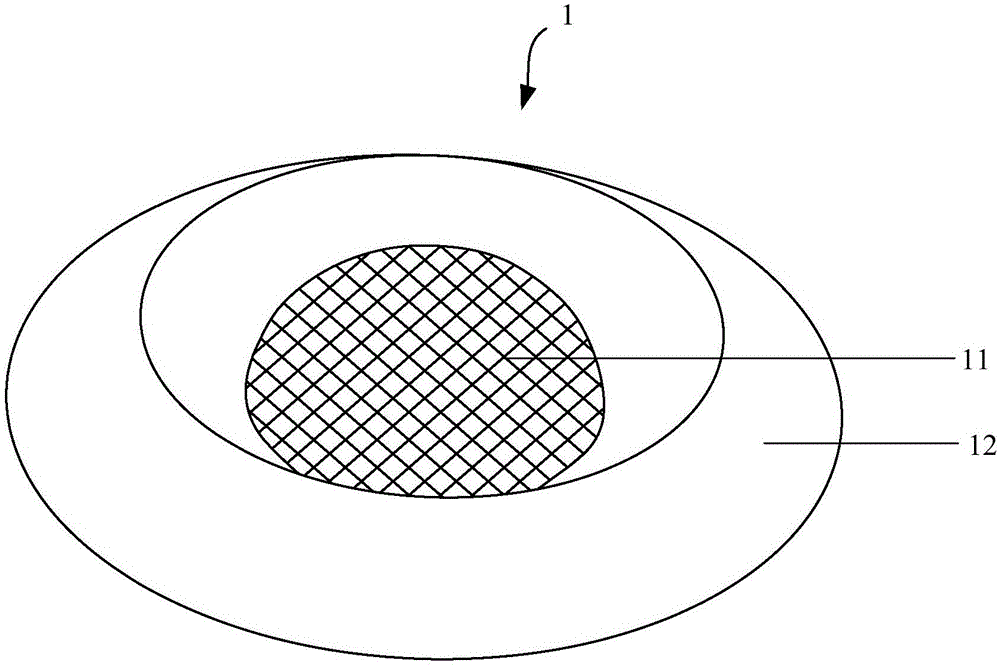

[0028] The optical film of the invention is used for converging light, and combines the advantages of convex lenses and prisms. It not only has high light transmittance, but also has high haze and good shielding performance, and improves the effect of converging light.

[0029] The optical film includes a plurality of optical structures, the optical structures include a convex lens structure and a prism structure, and the prism structure is located at the periphery of the convex lens structure. The prism structure located at the periphery has a strong converging effect on light and has a high light transmittance, thereby improving the light transmittance of the entire optical film and improving the brightness of the light source. The convex lens structure located in the middle has a higher haze, which can increase the shielding performance of the entire optical film. Therefore, the optical film of the present invention has the advantages of high light transmittance and high ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com